新闻资讯banner

About SMT patch introduction

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-15

- Views:0

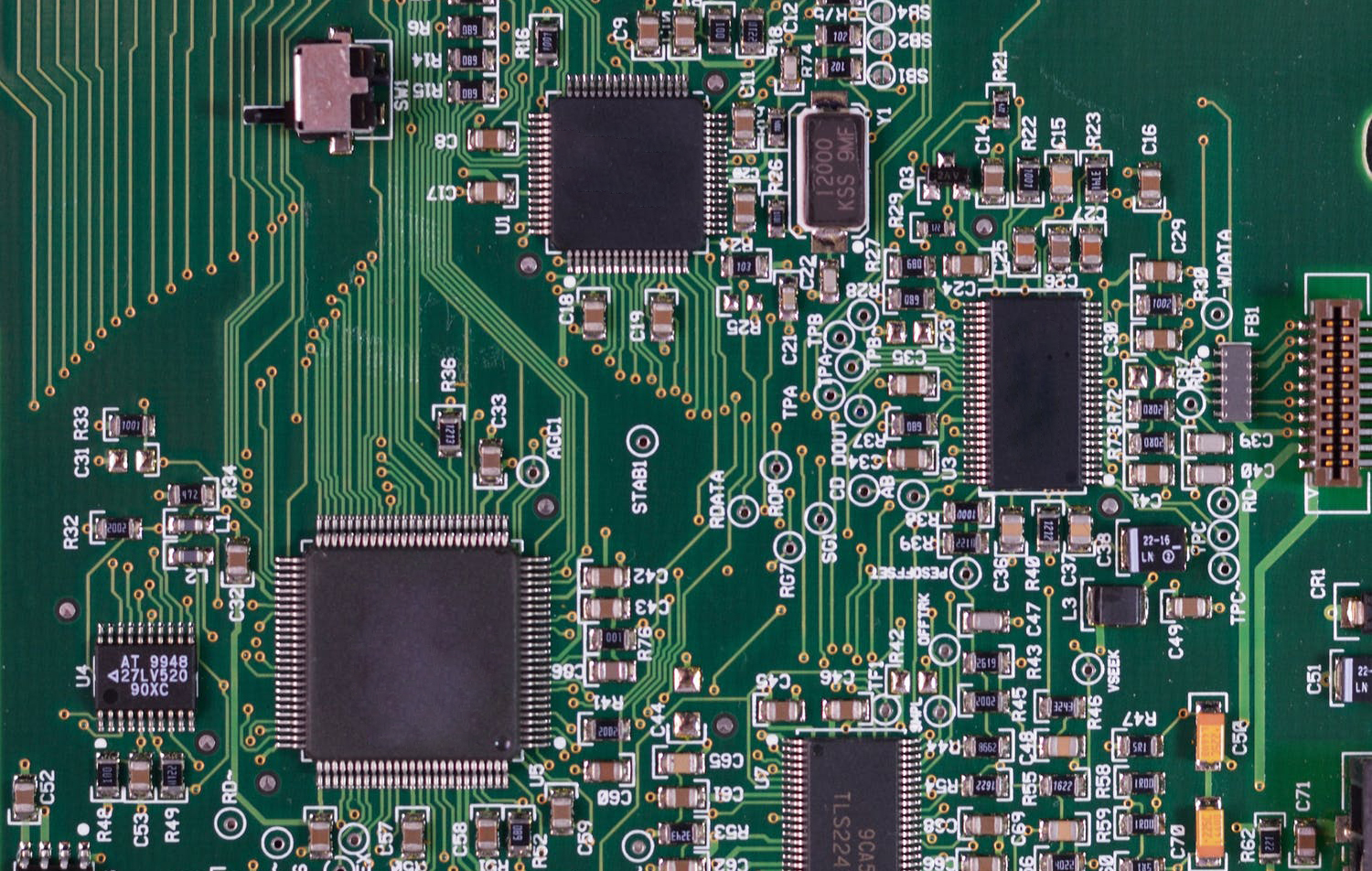

(Summary description)SMT is the abbreviation of Surface Mount Technology in English, which means surface mount (welding) technology in Chinese, that is, the technology of soldering electronic parts to the surface of the circuit board.

The advantage of using SMT technology is that it can greatly reduce the volume of electronic products, so that it can achieve the purpose of lighter, thinner and shorter.

However, there are also many people who regard SMD as SMT. Sometimes the two can be mixed, but there is still a difference in essence. SMD is the abbreviation of Surface Mount Device in English, and Chinese is surface mount welding parts, which generally refers to electronic parts that can use SMT technology. One refers to technology, and one refers to parts, so it is better to distinguish. But at this point, I believe some people will be...

About SMT patch introduction

(Summary description)SMT is the abbreviation of Surface Mount Technology in English, which means surface mount (welding) technology in Chinese, that is, the technology of soldering electronic parts to the surface of the circuit board.

The advantage of using SMT technology is that it can greatly reduce the volume of electronic products, so that it can achieve the purpose of lighter, thinner and shorter.

However, there are also many people who regard SMD as SMT. Sometimes the two can be mixed, but there is still a difference in essence. SMD is the abbreviation of Surface Mount Device in English, and Chinese is surface mount welding parts, which generally refers to electronic parts that can use SMT technology. One refers to technology, and one refers to parts, so it is better to distinguish. But at this point, I believe some people will be...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-15

- Views:0

SMT is the abbreviation of Surface Mount Technology in English, which means surface mount (welding) technology in Chinese, that is, the technology of soldering electronic parts to the surface of the circuit board.

The advantage of using SMT technology is that it can greatly reduce the volume of electronic products, so that it can achieve the purpose of lighter, thinner and shorter.

However, there are also many people who regard SMD as SMT. Sometimes the two can be mixed, but there is still a difference in essence. SMD is the abbreviation of Surface Mount Device in English, and Chinese is surface mount welding parts, which generally refers to electronic parts that can use SMT technology. One refers to technology, and one refers to parts, so it is better to distinguish. But at this point, I believe some people will be curious, how does SMT solder the electronic parts to the circuit board? Next, Sanjing will introduce to you.

The indispensable material for SMT patch is solder paste. As long as the solder paste is printed on the pads of the parts that need to be soldered, then the electronic parts are placed. The solder feet should be placed just on the position of the solder paste, and the solder paste can be reflowed at a high temperature. Soldering, the high temperature in the furnace is higher than the melting point of the solder paste (not high enough to burn the electronic parts), and the high temperature of the furnace will melt the solder paste. The solder paste becomes liquid, and the liquid solder paste will wrap the solder feet of the electronic parts. After passing through the cooling zone of the furnace, the solder paste will become solid again, and the electronic parts will be firmly soldered on the circuit board.

What are the benefits of adopting SMT technology for electronic products? First of all, the first is that electronic products can be designed to be lighter, thinner, shorter, and the parts become smaller, and the volume of the circuit board will also become smaller; secondly, more high-end products can be designed, which can be applied to more electronic products. Fields, such as CPUs and smart phones; the third is suitable for mass production. Because SMT technology replaces manual plug-in operations and uses automatic placement machines to place electronic parts, it is more suitable for mass production of high-quality and stable products. The fourth is to reduce production costs. The SMT complete line equipment is basically fully automated, from the printing machine to the placement machine to the reflow soldering, which not only increases the production capacity, but also reduces the labor cost.

Next, I will introduce SMT placement equipment.

Generally, a complete SMT production line routinely includes the following equipment: board loading machine, printing machine, docking station, SPI, placement machine, plug-in machine, reflow soldering, wave soldering, AOI, X-ray, loading machine and other equipment, The above equipment is a relatively complete smt wiring list equipment. Different factories can add or delete related equipment according to actual product needs, but the essential equipment includes printers, placement machines, and reflow soldering.

In addition to production equipment, testing equipment is also essential for SMT placement. SMT testing equipment includes: SPI solder paste tester, furnace temperature curve tester, AOI optical tester, ICT online tester, X-RAY test system, ATE test system, etc. SMT peripheral equipment: solder paste mixer, connecting table, splitter, loading and unloading machine, loading and unloading machine, buffer machine, etc.

The above is about the introduction of SMT patch, I will introduce it to you today, I hope it can be helpful to everyone! For more information, please go to the official website of Sanjing (http://www.sajpcba.cn) to view.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback