新闻资讯banner

Common causes and solutions for PCBA pseudo welding

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-12-27

- Views:0

(Summary description)In the PCBA processing process, pseudo soldering is an important reason that affects the quality of the circuit board. PCBA pseudo welding is also called cold welding. From the surface, there is no problem with welding, but the actual internal components are not connected, or the internal connection is unstable, which affects the circuit characteristics, resulting in unqualified PCB circuit boards or even scrapped. In addition, if false welding occurs, it needs to be reprocessed, which will not only increase labor pressure, but also reduce production efficiency and bring losses to the enterprise. Therefore, we must pay attention to the PCBA pseudo-welding phenomenon.

Let’s take a look at the common causes and solutions of PCBA pseudo-welding in the following Sanjing:

PCBA pseudo-soldering is a common circuit error. There are two common reasons for ...

Common causes and solutions for PCBA pseudo welding

(Summary description)In the PCBA processing process, pseudo soldering is an important reason that affects the quality of the circuit board. PCBA pseudo welding is also called cold welding. From the surface, there is no problem with welding, but the actual internal components are not connected, or the internal connection is unstable, which affects the circuit characteristics, resulting in unqualified PCB circuit boards or even scrapped. In addition, if false welding occurs, it needs to be reprocessed, which will not only increase labor pressure, but also reduce production efficiency and bring losses to the enterprise. Therefore, we must pay attention to the PCBA pseudo-welding phenomenon.

Let’s take a look at the common causes and solutions of PCBA pseudo-welding in the following Sanjing:

PCBA pseudo-soldering is a common circuit error. There are two common reasons for ...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-12-27

- Views:0

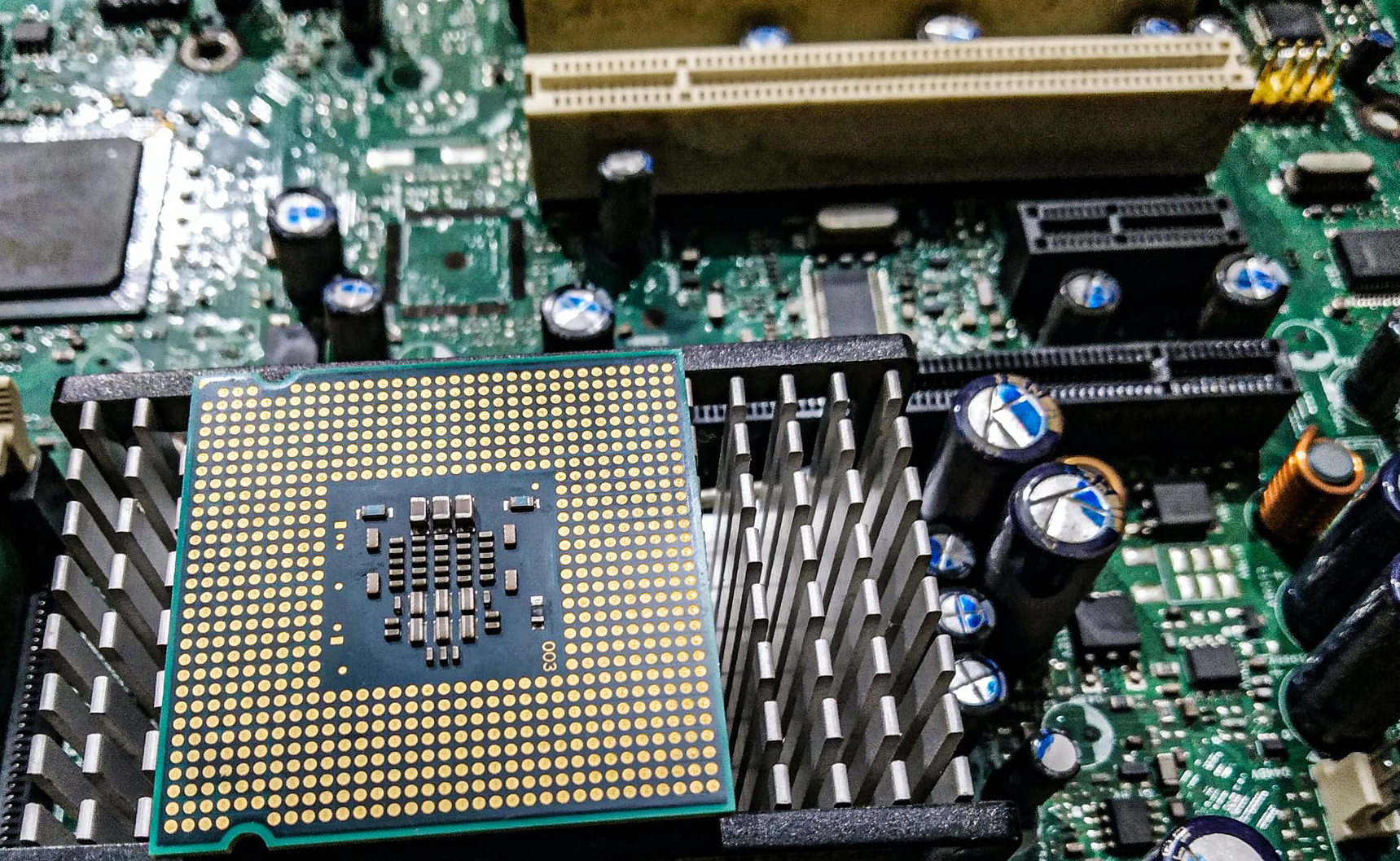

In the PCBA processing process, pseudo soldering is an important reason that affects the quality of the circuit board. PCBA pseudo welding is also called cold welding. From the surface, there is no problem with welding, but the actual internal components are not connected, or the internal connection is unstable, which affects the circuit characteristics, resulting in unqualified PCB circuit boards or even scrapped. In addition, if false welding occurs, it needs to be reprocessed, which will not only increase labor pressure, but also reduce production efficiency and bring losses to the enterprise. Therefore, we must pay attention to the PCBA pseudo-welding phenomenon.

Let’s take a look at the common causes and solutions of PCBA pseudo-welding in the following Sanjing:

PCBA pseudo-soldering is a common circuit error. There are two common reasons for solder joints: one is in PCBA processing, due to improper production, poor soldering or less tin, component feet or pads are not opened, etc., sometimes the circuit The circuit board will be in an unstable state when it is turned on or off. Second, due to long-term use of electrical appliances, some parts with severe heat generation are prone to aging and peeling, or the solder joints at the solder joints produce impurities.

However, these problems are not without solutions. The first and most important thing is to choose the PCB substrate material reasonably, and the second is to protect the components from moisture. Soldering paste and flux are required, preferably a reflow soldering machine. If manual welding is selected, the manual welding technique is required to be better.

If only the PCB circuit board welding quality is unqualified and needs repair, you need to use a magnifying glass to observe the PCBA solder joints through the appearance, focus on the parts that generate a lot of heat, shake the movable parts by hand, and observe whether the solder joints are loose, according to the failure The phenomenon judges the approximate fault range, and then repairs it.

The above is about the common causes and solutions of PCBA pseudo-welding, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback