新闻资讯banner

Four elements of PCBA patch processing quality control

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-06-26

- Views:0

(Summary description)We know that quality control is an indispensable link in the PCBA manufacturing process. Next, Sanjing will share with you what are the elements of PCBA quality control in the patch processing link.

1. SMT patch assembly

In SMT chip processing, the quality control details of solder paste printing and reflow soldering temperature control systems are the key to the PCBA manufacturing process. For the printing of high-precision circuit boards with special and complex processes, because of higher quality requirements and more demanding processing requirements, laser stencils need to be used according to specific conditions. At the same time, according to...

Four elements of PCBA patch processing quality control

(Summary description)We know that quality control is an indispensable link in the PCBA manufacturing process. Next, Sanjing will share with you what are the elements of PCBA quality control in the patch processing link.

1. SMT patch assembly

In SMT chip processing, the quality control details of solder paste printing and reflow soldering temperature control systems are the key to the PCBA manufacturing process. For the printing of high-precision circuit boards with special and complex processes, because of higher quality requirements and more demanding processing requirements, laser stencils need to be used according to specific conditions. At the same time, according to...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-06-26

- Views:0

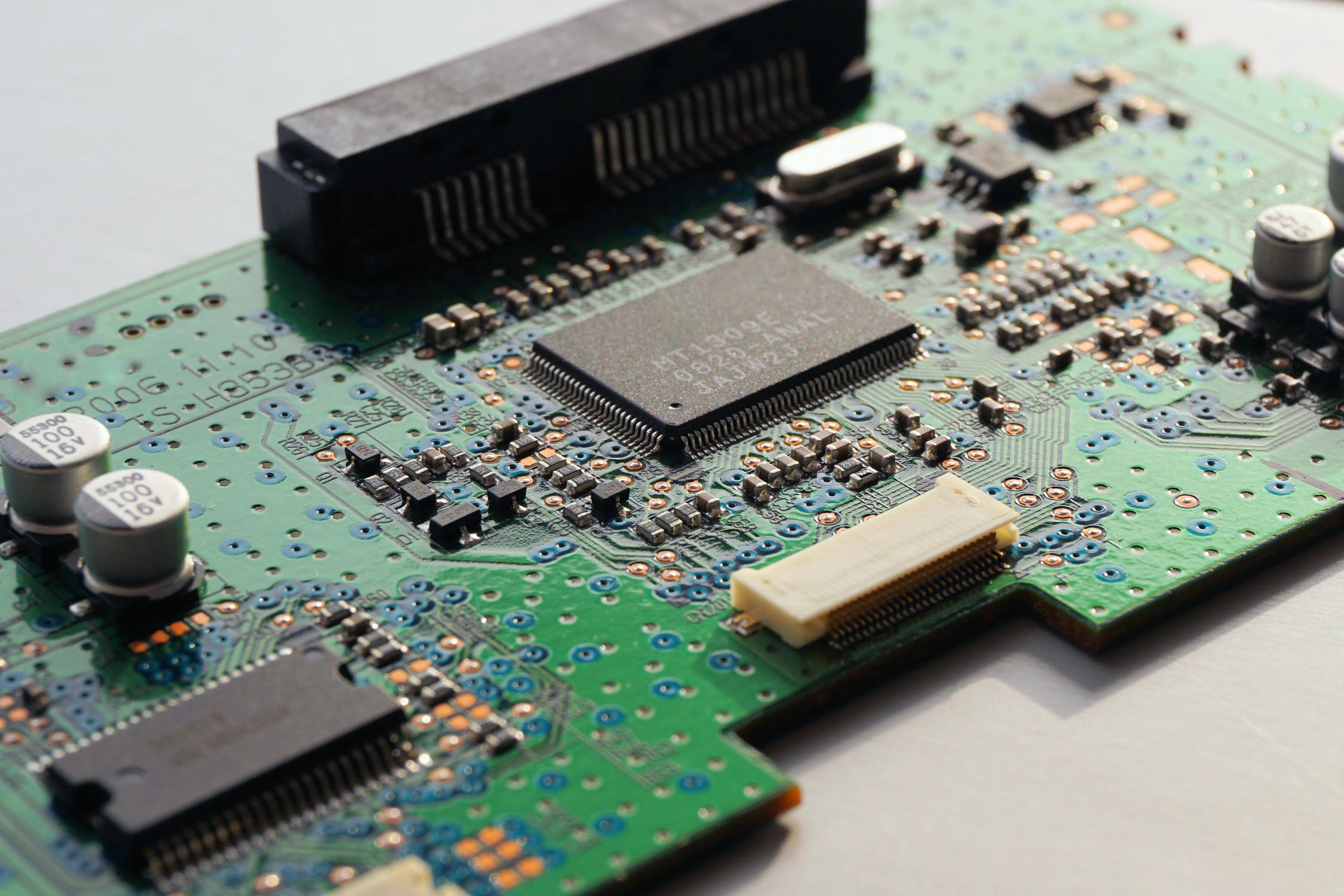

We know that quality control is an indispensable link in the PCBA manufacturing process. Next, Sanjing will share with you what are the elements of PCBA quality control in the patch processing link.

1. SMT patch assembly

In SMT chip processing, the quality control details of solder paste printing and reflow soldering temperature control systems are the key to the PCBA manufacturing process. For the printing of high-precision circuit boards with special and complex processes, because of higher quality requirements and more demanding processing requirements, laser stencils need to be used according to specific conditions. At the same time, according to PCB manufacturing requirements and customer product characteristics, some may need to increase U-shaped holes or reduce steel mesh holes, and certain processing of the steel mesh is required according to the PCBA processing process requirements. Among them, the temperature control accuracy of the reflow oven is very important for the wetting of the solder paste and the firmness of the stencil welding. It can be adjusted according to the normal SOP operation guide to minimize the quality defects of the PCBA patch processing in the SMT link. In addition, strict implementation of AOI testing can also greatly reduce defects caused by human factors.

Two, DIP plug-in post welding

Although DIP plug-in post-welding is the last process, it is also a very important link in the circuit board processing stage. Especially in the DIP plug-in post-welding process, the consideration of the furnace fixture for wave soldering is very critical. According to the different requirements of customers' products, how to use the furnace fixture to maximize the yield rate and reduce the soldering defects such as continuous tin, less tin, and more tin. PCBA processing plants need to continuously summarize experience in practice and in the process of experience accumulation Achieve technical upgrades.

Three, test and program firing

In most cases, customers who prefer one-stop PCBA processing also have certain requirements for PCBA back-end testing. These back-end tests generally include: ICT (circuit test), FCT (functional test), burn test (aging test), temperature and humidity test, drop test, etc.

Four, PCBA manufacturing test

The manufacturability report is an evaluation work before production after we receive the customer's production contract. In the previous DFM report, we can provide customers with some suggestions before PCBA processing, such as setting up some key test points on the PCBA (test point) to test the soldering of the circuit board and the continuity of the circuit after PCBA processing , Connectivity, etc. If conditions permit, you can ask the customer to provide the back-end program, and then burn the PCBA program into the core master IC through the burner. In this way, the circuit board can be tested directly by touch, which can not only test and inspect the integrity of the entire PCBA, but also find defective products in time.

Well, the above is our sharing of the four elements of quality control in PCBA patch processing, I hope it will be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback