新闻资讯banner

How to carry out PCBA board reliability test

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-04

- Views:0

(Summary description)We know that the PCBA manufacturing process is extremely complicated. In addition to attaching importance to SMT chip processing, any material problems will have many collateral effects, which will affect the overall effect of the PCBA board. Therefore, in view of this situation, it is necessary to have sufficient material testing capabilities, supplier management capabilities, technical analysis capabilities, and reliability testing capabilities.

However, reliability testing is often ignored by PCBA processing manufacturers. Many times they will think that as long as the PCBA test is okay, in fact, many PCBA boards will have many problems in the terminal products, such as unstable performance and use. Short life, etc., therefore, PCBA reliability testing is an indispensable link. How should the PCBA reliability test be carried out? Let’s take a look at the following Sanjing:

(1) Aging test. Place the PCBA board with intact test functions under specific temperature and humidity conditions, perform repeated switch machine tests, simulated function operation, load operations, etc., and check the stability of the PCBA through...

How to carry out PCBA board reliability test

(Summary description)We know that the PCBA manufacturing process is extremely complicated. In addition to attaching importance to SMT chip processing, any material problems will have many collateral effects, which will affect the overall effect of the PCBA board. Therefore, in view of this situation, it is necessary to have sufficient material testing capabilities, supplier management capabilities, technical analysis capabilities, and reliability testing capabilities.

However, reliability testing is often ignored by PCBA processing manufacturers. Many times they will think that as long as the PCBA test is okay, in fact, many PCBA boards will have many problems in the terminal products, such as unstable performance and use. Short life, etc., therefore, PCBA reliability testing is an indispensable link. How should the PCBA reliability test be carried out? Let’s take a look at the following Sanjing:

(1) Aging test. Place the PCBA board with intact test functions under specific temperature and humidity conditions, perform repeated switch machine tests, simulated function operation, load operations, etc., and check the stability of the PCBA through...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-04

- Views:0

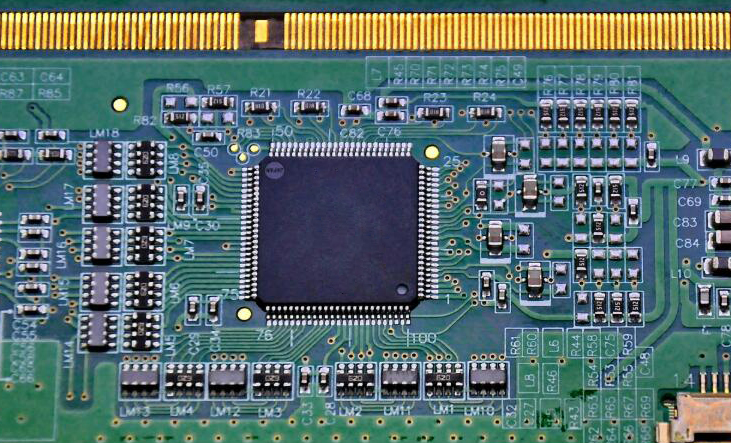

We know that the PCBA manufacturing process is extremely complicated. In addition to attaching importance to SMT chip processing, any material problems will have many collateral effects, which will affect the overall effect of the PCBA board. Therefore, in view of this situation, it is necessary to have sufficient material testing capabilities, supplier management capabilities, technical analysis capabilities, and reliability testing capabilities.

However, reliability testing is often ignored by PCBA processing manufacturers. Many times they will think that as long as the PCBA test is okay, in fact, many PCBA boards will have many problems in the terminal products, such as unstable performance and use. Short life, etc., therefore, PCBA reliability testing is an indispensable link. How should the PCBA reliability test be carried out? Let’s take a look at the following Sanjing:

(1) Aging test. Place the PCBA board with intact test functions under specific temperature and humidity conditions, perform repeated switch machine tests, simulated function operation, load operations, etc., and check the stability of the PCBA through 24-72 hours of uninterrupted operation. Because the aging test takes a long time, it is not suitable for large-scale batch operations. Generally, sampling tests are selected, and the overall yield rate of the batch of products is judged by sampling the qualified rate.

(2) Vibration test. When many PCBA boards are delivered to customers, it is inevitable that they will encounter some problems caused by vibration during transportation, such as component shedding and pad cracks. Through the vibration test, the vibration effect during transportation can be effectively simulated, and defects in the welding process can be exposed, so as to avoid batch welding defects to the greatest extent and improve the overall yield rate of delivery.

(3) Surge impact test. This situation often occurs in PCBA processing: PCBA runs well under normal voltage, but it will appear bad when it encounters a surge. This is because many circuits are designed without considering the fatal impact of instantaneous voltage or current impact on the entire circuit, so it is necessary to take samples for surge impact testing before mass production.

(4) Packaging drop test. Compared with the previous tests, this test is the easiest to be overlooked. Even if all the previous links are intact, if the packaging is not in place, dropping during transportation will cause damage to the PCBA, so it is necessary to test the packaging.

Strictly speaking, PCBA reliability testing is not limited to the above mentioned items. If you want to pursue higher quality, you can negotiate a reliability test plan with customers according to the actual situation.

The above is about how to carry out the reliability test of PCBA board, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback