新闻资讯banner

How to control each process of PCBA processing

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-27

- Views:0

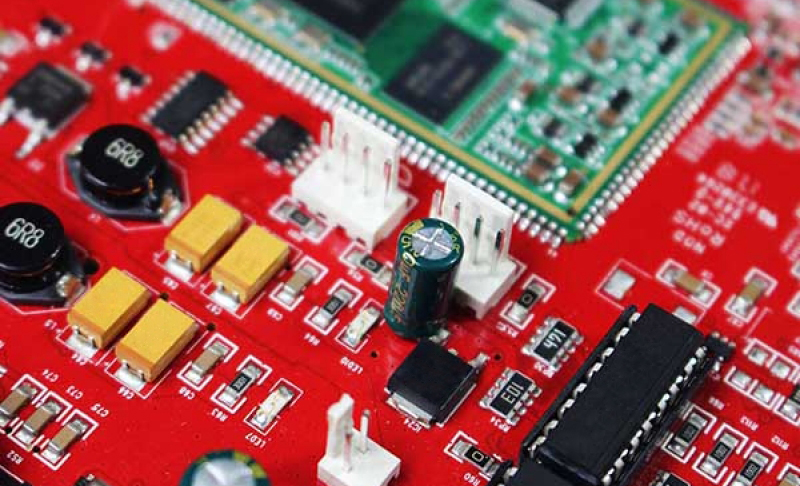

(Summary description)PCBA is a series of processing processes such as PCB circuit board manufacturing, component procurement and inspection, SMT chip processing, plug-in processing, program firing, and testing. PCBA processing involves many links, and the quality of each link must be controlled to produce good products. Let's take a look at the contents of each process of PCBA processing in the following Sanjing:

1. PCB circuit board manufacturing. Generally, after receiving a PCBA order, you need to analyze the Gerber file first. Pay attention to the relationship between the PCB hole spacing and the board's bearing capacity. Do not cause bending or breakage. At the same time, you should also consider whether the wiring is affected by high-frequency signal interference, impedance, etc. factor.

2. Procurement and inspection of components. The procurement of components requires strict control of channels. It is best to pick up the goods from large traders or original factories to avoid purchasing fake or second-hand materials. In addition, a special inspection post for incoming materials can be set up to strictly inspect PCBs, ICs and other common materials to ensure that the components are fault-free.

Here are the inspection methods for various components and materials:...

How to control each process of PCBA processing

(Summary description)PCBA is a series of processing processes such as PCB circuit board manufacturing, component procurement and inspection, SMT chip processing, plug-in processing, program firing, and testing. PCBA processing involves many links, and the quality of each link must be controlled to produce good products. Let's take a look at the contents of each process of PCBA processing in the following Sanjing:

1. PCB circuit board manufacturing. Generally, after receiving a PCBA order, you need to analyze the Gerber file first. Pay attention to the relationship between the PCB hole spacing and the board's bearing capacity. Do not cause bending or breakage. At the same time, you should also consider whether the wiring is affected by high-frequency signal interference, impedance, etc. factor.

2. Procurement and inspection of components. The procurement of components requires strict control of channels. It is best to pick up the goods from large traders or original factories to avoid purchasing fake or second-hand materials. In addition, a special inspection post for incoming materials can be set up to strictly inspect PCBs, ICs and other common materials to ensure that the components are fault-free.

Here are the inspection methods for various components and materials:...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-27

- Views:0

PCBA is a series of processing processes such as PCB circuit board manufacturing, component procurement and inspection, SMT chip processing, plug-in processing, program firing, and testing. PCBA processing involves many links, and the quality of each link must be controlled to produce good products. Let's take a look at the contents of each process of PCBA processing in the following Sanjing:

1. PCB circuit board manufacturing. Generally, after receiving a PCBA order, you need to analyze the Gerber file first. Pay attention to the relationship between the PCB hole spacing and the board's bearing capacity. Do not cause bending or breakage. At the same time, you should also consider whether the wiring is affected by high-frequency signal interference, impedance, etc. factor.

2. Procurement and inspection of components. The procurement of components requires strict control of channels. It is best to pick up the goods from large traders or original factories to avoid purchasing fake or second-hand materials. In addition, a special inspection post for incoming materials can be set up to strictly inspect PCBs, ICs and other common materials to ensure that the components are fault-free.

Here are the inspection methods for various components and materials: ①PCB: After the reflow oven temperature test, no flying leads, check whether the board surface is bent, whether the via hole is blocked or leaks ink. ②IC: Check whether the silk screen is completely consistent with the BOM, and keep it at constant temperature and humidity. ③Other common materials: check the silk screen, appearance, power-on measurement, etc., the inspection items adopt random inspection methods, and the random inspection ratio is generally 1 to 3%.

3. SMT patch processing. Solder paste printing and reflow oven temperature control are the key, and it is very important to use laser stencils of good quality and meeting process requirements. According to PCB requirements, some steel mesh holes need to be enlarged or reduced, or U-shaped holes are used to make steel mesh according to process requirements. The furnace temperature and speed control of the reflow soldering is very critical to the solder paste infiltration and soldering reliability, and it can be controlled in accordance with the normal SOP operation guidelines. In addition, AOI testing needs to be strictly implemented to minimize the defects caused by human factors.

4. DIP plug-in processing. In the plug-in process, the mold design for wave soldering is the key. How to use the mold to maximize the yield after the furnace is a process that PE engineers must continue to practice and summarize experience.

Five, program firing. In the previous DFM report, it is recommended to set some test points on the PCB, the purpose is to test the PCBA circuit continuity after the PCB and all components are soldered.

Sixth, PCBA board test. For orders with PCBA test requirements, the main test content includes ICT, FCT, aging test, temperature and humidity test, drop test, etc., which can be operated according to the customer's test plan and summarized report data.

The above is about how to control the various processes of PCBA processing, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback