新闻资讯banner

How to control the quality of PCBA processing

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-09-09

- Views:0

(Summary description)We know that the process of PCBA processing is very cumbersome, no matter which part of the problem occurs, it will lead to poor product processing. So how to control the quality of PCBA processing? Let’s take a look at the following Sanjing:

Quality control is an important step to ensure product quality and production efficiency, so the most important thing is to establish a complete quality management system (ISO). Take reflow soldering as an example. Although the temperature in the furnace can be controlled by the furnace temperature control system and temperature sensor in the reflow soldering, the actual temperature of the solder joints on the PCB is not necessarily equal to the preset temperature of the reflow soldering. Although the reflow soldering machine works normally and the temperature control is...

How to control the quality of PCBA processing

(Summary description)We know that the process of PCBA processing is very cumbersome, no matter which part of the problem occurs, it will lead to poor product processing. So how to control the quality of PCBA processing? Let’s take a look at the following Sanjing:

Quality control is an important step to ensure product quality and production efficiency, so the most important thing is to establish a complete quality management system (ISO). Take reflow soldering as an example. Although the temperature in the furnace can be controlled by the furnace temperature control system and temperature sensor in the reflow soldering, the actual temperature of the solder joints on the PCB is not necessarily equal to the preset temperature of the reflow soldering. Although the reflow soldering machine works normally and the temperature control is...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-09-09

- Views:0

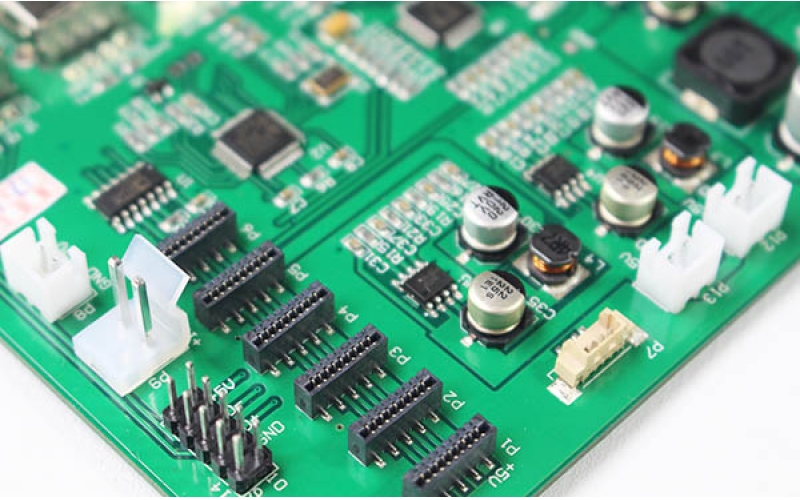

We know that the process of PCBA processing is very cumbersome, no matter which part of the problem occurs, it will lead to poor product processing. So how to control the quality of PCBA processing? Let’s take a look at the following Sanjing:

Quality control is an important step to ensure product quality and production efficiency, so the most important thing is to establish a complete quality management system (ISO). Take reflow soldering as an example. Although the temperature in the furnace can be controlled by the furnace temperature control system and temperature sensor in the reflow soldering, the actual temperature of the solder joints on the PCB is not necessarily equal to the preset temperature of the reflow soldering. Although the reflow soldering machine works normally and the temperature control is within the temperature control accuracy range of the equipment, due to uncontrollable factors such as the quality of the PCB board, the assembly density, and the number of PCBs entering the furnace, the furnace temperature curve will also fluctuate accordingly. Therefore, the temperature of the reflow soldering machine has to be continuously monitored to ensure smooth quality control.

However, the production line is changing. For example, equipment aging, personnel adjustments, and material quality will affect each other, which will cause fluctuations in the quality of PCBA processed products. Therefore, it is quite challenging to adopt effective and continuous quality monitoring without affecting production and increasing production costs.

The ISO review agency mainly reviews the PCBA processing and production quality control plan, establishes that the production site meets the standards and implements it in accordance with the specified quality control plan and measures. In addition, the audit content mainly includes the production site environment and safety assembly, production equipment, production documents, production procedures and work instructions, node settings of the production process, purchase and storage of raw materials, and professional capabilities of production operators (measurement knowledge, statistics Learning knowledge, causal analysis ability, and in-depth understanding of equipment), etc.

Therefore, each position should strictly follow the work instructions to carry out operations, so that the production can be standardized to the greatest extent, which is beneficial to reduce production quality problems. In addition, strict quality control is required from raw material procurement to production processing and final shipment inspection.

The above is about how to control PCBA processing quality, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback