新闻资讯banner

How to repair and maintain circuit boards in SMT chip processing and production

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-26

- Views:0

(Summary description)In the process of SMT chip processing, production and use, if there are processing errors, improper use or aging of components, it will cause abnormal operation of the PCB board or even poor use of the entire product. However, because many products only have problems with internal components, they do not need to be replaced all, which requires certain repairs and maintenance of the circuit boards in the products. So what are the specific steps? Let's take a look at the following Sanjing belts.

The first step is to check the components. In the SMT chip processing plant, when the product needs to be repaired, it is first necessary to determine whether the components of each solder joint have errors, omissions, and reverses. At the same time, it should also...

How to repair and maintain circuit boards in SMT chip processing and production

(Summary description)In the process of SMT chip processing, production and use, if there are processing errors, improper use or aging of components, it will cause abnormal operation of the PCB board or even poor use of the entire product. However, because many products only have problems with internal components, they do not need to be replaced all, which requires certain repairs and maintenance of the circuit boards in the products. So what are the specific steps? Let's take a look at the following Sanjing belts.

The first step is to check the components. In the SMT chip processing plant, when the product needs to be repaired, it is first necessary to determine whether the components of each solder joint have errors, omissions, and reverses. At the same time, it should also...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-26

- Views:0

In the process of SMT chip processing, production and use, if there are processing errors, improper use or aging of components, it will cause abnormal operation of the PCB board or even poor use of the entire product. However, because many products only have problems with internal components, they do not need to be replaced all, which requires certain repairs and maintenance of the circuit boards in the products. So what are the specific steps? Let's take a look at the following Sanjing belts.

The first step is to check the components. In the SMT chip processing plant, when the product needs to be repaired, it is first necessary to determine whether the components of each solder joint have errors, omissions, and reverses. At the same time, it should also consider the authenticity of no materials. If the problems of error, leakage, reverse, and authenticity are eliminated, when you get a faulty circuit board, you must first check whether the circuit board is intact, and whether each component is incorrectly inserted or has obvious signs of burnout.

Second, analysis of welding status. Generally speaking, the defective circuit board is basically 80% likely to be caused by defective solder joints. Whether the solder joints are full or abnormal, firstly refer to the ISO9001 quality management system standards. At the same time, there are various SMT processing welding quality standards to check whether there are false welding, false welding and short circuits, and whether the copper skin is obviously lifted and so on. The undesirable situation arises. If there are any of the above-listed conditions, you need to repair the defective points of the product, if not, you can proceed to the next step.

Third, component orientation detection. In the process of this link, we have basically eliminated some defects that can be observed with the naked eye through the previous two links. Therefore, we need to carefully check the direction of the components, such as checking diodes and electrolytic capacitors, which are the most used on circuit boards. Whether components or components that require positive and negative poles are inserted in the wrong direction.

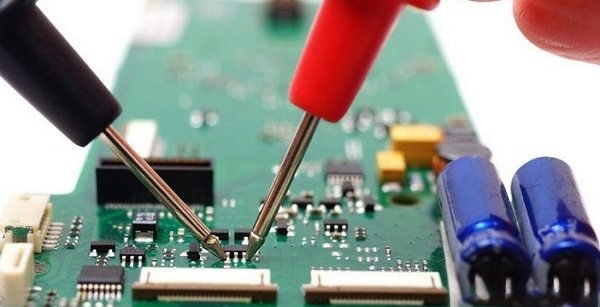

Fourth, component tool inspection. If there is no problem with the naked eye in the first few links, we need to borrow some auxiliary tools at this time, such as a multimeter. The most commonly used in SMT chip processing plants is to use a multimeter to measure whether the resistance value of components such as resistors, capacitors, and transistors does not meet the normal value, the resistance value becomes larger or smaller, whether the capacitor is open circuit, whether the inductance is open circuit, etc.

Fifth, power-on test. After all the above steps are completed, the conventional problems of the components can basically be eliminated, and then the power-on test is required. If the circuit board will not be damaged by ablation due to short circuit or bridge connection after power on, you can check whether other corresponding functions of the circuit board are normal.

The above is the introduction about how to repair and maintain the circuit board in the SMT chip processing and production. I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback