新闻资讯banner

Lead-free SMT circuit board land requirements

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-04

- Views:0

(Summary description)So far, although the country has not put forward special requirements for the design of lead-free SMT circuit boards, and there is no unified SMT circuit board specification standard in the industry, in order to respond to the call of the country, it is necessary to consider circuit board material selection, manufacturing, use and Factors such as recovery costs.

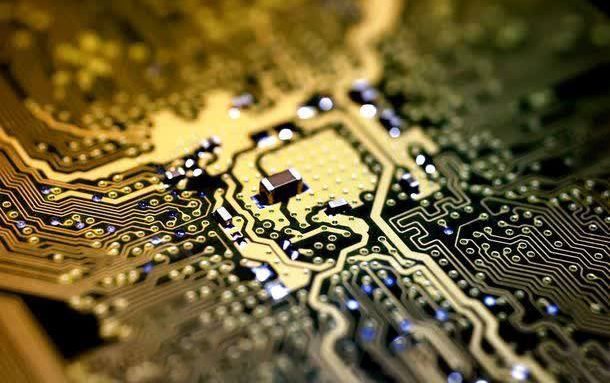

When realizing lead-free SMT circuit board manufacturing, designers should always pay attention to DFM issues, the choice of circuit board surface plating, the choice of laminate materials and through-hole considerations, the choice of components, reliability issues, and Sn-Pb Solder and lead-free component soldering or lead-free solder is compatible with traditional leaded component soldering and other issues. Let’s take a look at the following Sanjing:

(1) In order to reduce the poor soldering on the surface of the printed circuit board during SMT patch processing, careful consideration should be given to heat dissipation design, such as uniform component distribution, copper foil distribution, printed circuit board...

Lead-free SMT circuit board land requirements

(Summary description)So far, although the country has not put forward special requirements for the design of lead-free SMT circuit boards, and there is no unified SMT circuit board specification standard in the industry, in order to respond to the call of the country, it is necessary to consider circuit board material selection, manufacturing, use and Factors such as recovery costs.

When realizing lead-free SMT circuit board manufacturing, designers should always pay attention to DFM issues, the choice of circuit board surface plating, the choice of laminate materials and through-hole considerations, the choice of components, reliability issues, and Sn-Pb Solder and lead-free component soldering or lead-free solder is compatible with traditional leaded component soldering and other issues. Let’s take a look at the following Sanjing:

(1) In order to reduce the poor soldering on the surface of the printed circuit board during SMT patch processing, careful consideration should be given to heat dissipation design, such as uniform component distribution, copper foil distribution, printed circuit board...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-04

- Views:0

So far, although the country has not put forward special requirements for the design of lead-free SMT circuit boards, and there is no unified SMT circuit board specification standard in the industry, in order to respond to the call of the country, it is necessary to consider circuit board material selection, manufacturing, use and Factors such as recovery costs.

When realizing lead-free SMT circuit board manufacturing, designers should always pay attention to DFM issues, the choice of circuit board surface plating, the choice of laminate materials and through-hole considerations, the choice of components, reliability issues, and Sn-Pb Solder and lead-free component soldering or lead-free solder is compatible with traditional leaded component soldering and other issues. Let’s take a look at the following Sanjing:

(1) In order to reduce the poor soldering on the surface of the printed circuit board during SMT patch processing, careful consideration should be given to heat dissipation design, such as uniform component distribution, copper foil distribution, printed circuit board layout, etc., to reduce the possibility of soldering problems .

(2) The oval-shaped SMT printed circuit board pad can reduce the phenomenon of copper exposure on the pad after SMT chip soldering. The use of SMD pad design in the transition stage of BGA and CSP is beneficial to exhaust, reducing the generation of holes, and the excess on the pad. The hole should use blind hole technology and be flush with the surface of the pad. In addition, the pad design of BGA and CSP is divided into two types: SMD and NSMD according to different solder mask methods.

(3) Lead-free wave soldering pads for through-hole components during the transition period, such as double-sided soldering (reflow soldering on side A, wave soldering on side B), large components on side A and wave soldering pads for through-hole components can also be used SMD pad design can reduce solder joints and pad peeling.

(4) The aperture of the insertion hole of the through-hole component needs to be appropriately enlarged, which is beneficial to increase the filling height of the solder in the insertion hole.

(5) Finally, environmental protection design is promoted. Since WEEE is a directive on the recycling and reuse of waste electrical and electronic equipment, it stipulates the principle of who manufactures the recycling. Therefore, the cost of WEEE recycling and reuse should be taken into consideration when designing materials. Select process materials, SMT printed circuit board materials, components and other parts according to the environmental conditions and service life of the product, including the selection of SMT chip processing and assembly methods and SMT processing and manufacturing process design. Excessive selection of high-quality, long-life, and high-reliability parts and materials will not only increase the manufacturing cost of the product, but also increase the cost of recycling and reusing scrap electrical and electronic equipment.

The above is about the requirements of lead-free SMT circuit board pads, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback