新闻资讯banner

Methods to improve PCBA soldering porosity problem

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-08-11

- Views:0

(Summary description)When it comes to PCBA soldering, the most common soldering we usually do are: reflow soldering, wave soldering, manual soldering and immersion tin soldering. The welding method is different, so the welding process will be different. The following Sanjing will give you a brief understanding in turn.

The first is reflow soldering: in the PCBA soldering process, the first process is reflow soldering. This step is generally after the SMT patch is completed, the PCB board is placed in the reflow oven to solder the patch components.

Wave soldering: This soldering method is to insert the components on the PCB board after the reflow soldering is completed, and complete the soldering of the inserted components and the PCB board through the wave soldering furnace...

Methods to improve PCBA soldering porosity problem

(Summary description)When it comes to PCBA soldering, the most common soldering we usually do are: reflow soldering, wave soldering, manual soldering and immersion tin soldering. The welding method is different, so the welding process will be different. The following Sanjing will give you a brief understanding in turn.

The first is reflow soldering: in the PCBA soldering process, the first process is reflow soldering. This step is generally after the SMT patch is completed, the PCB board is placed in the reflow oven to solder the patch components.

Wave soldering: This soldering method is to insert the components on the PCB board after the reflow soldering is completed, and complete the soldering of the inserted components and the PCB board through the wave soldering furnace...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-08-11

- Views:0

When it comes to PCBA soldering, the most common soldering we usually do are: reflow soldering, wave soldering, manual soldering and immersion tin soldering. The welding method is different, so the welding process will be different. The following Sanjing will give you a brief understanding in turn.

The first is reflow soldering: in the PCBA soldering process, the first process is reflow soldering. This step is generally after the SMT patch is completed, the PCB board is placed in the reflow oven to solder the patch components.

Wave soldering: This soldering method is to insert the components on the PCB board after the reflow soldering is completed, and complete the soldering of the inserted components and the PCB board through the wave soldering furnace.

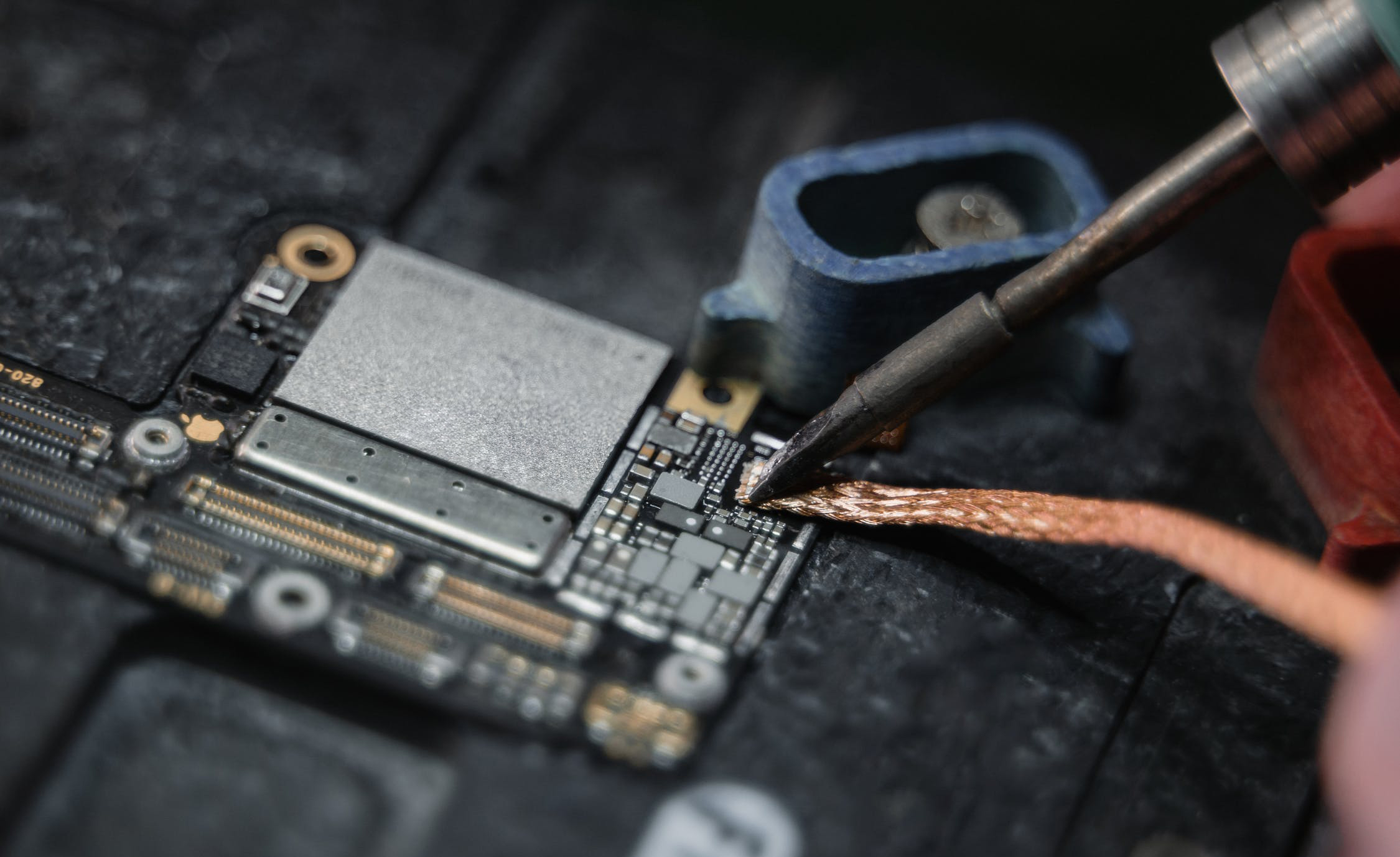

Manual welding: As the name suggests, welding is performed manually, and the main welding tool used is an electric soldering iron.

Dip soldering: For some large components or those that cannot pass wave soldering due to certain factors, soldering is often done with a tin furnace. This welding method is simpler and more convenient than other welding methods.

PCBA consists of multiple processes, and only through different welding methods can a complete PCBA board be produced.

However, during soldering, porosity (bubbles) can easily occur if you are not careful. This phenomenon is more common in reflow soldering and wave soldering processes. If it is not avoided as much as possible, it will cause damage to our PCB board. Therefore, in view of this situation, there are mainly the following solutions:

①Workshop humidity control: generally controlled between 40% and 60%. ② Solder paste quality control: When we choose solder paste, we should choose good quality solder paste, because the water in the solder paste can easily lead to pores and tin beads. At the same time, the solder paste stirring and temperature recovery should also be performed according to the actual operation. The solder paste should not be exposed to the air for too long. Reflow soldering should be carried out in time after the solder paste is printed. ③Baking: Baking PCB boards and components that have been exposed to the air for a long time to prevent moisture in the air from entering. ④ Furnace temperature curve setting and optimization: the temperature of the preheating zone should not be too low, the flux must be fully volatilized, the heating rate and the furnace passing speed should not be too fast, and the furnace temperature test needs to be carried out twice a day. ⑤Flux spraying: During wave soldering, the flux should not be sprayed too much.

In short, there are many factors that affect PCBA air holes. From the initial PCB design to the final production process, it is easy to cause various defects. Just like the soldering air holes we talked about today, you can design from the PCB. , PCB humidity, furnace temperature, flux, chain speed, tin wave height and solder composition, etc., only after continuous debugging of each link of the process, it is possible to finally produce good quality PCBA boards.

Regarding the method to improve the PCBA soldering porosity problem, Sanjing introduced here today, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback