新闻资讯banner

PCB common problems and solutions

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-07-16

- Views:0

(Summary description)①The PCB board is short-circuited. This problem is one of the common faults that directly cause the PCB board to fail to work. There are many reasons for this problem. The biggest cause of PCB short circuit is improper solder pad design. The solution is to change the round solder pad to The oval shape increases the distance between points to prevent short circuits.

Secondly, the improper design of the direction of the PCB parts will also cause the board to short-circuit and fail to work. Therefore, the part orientation can be appropriately modified...

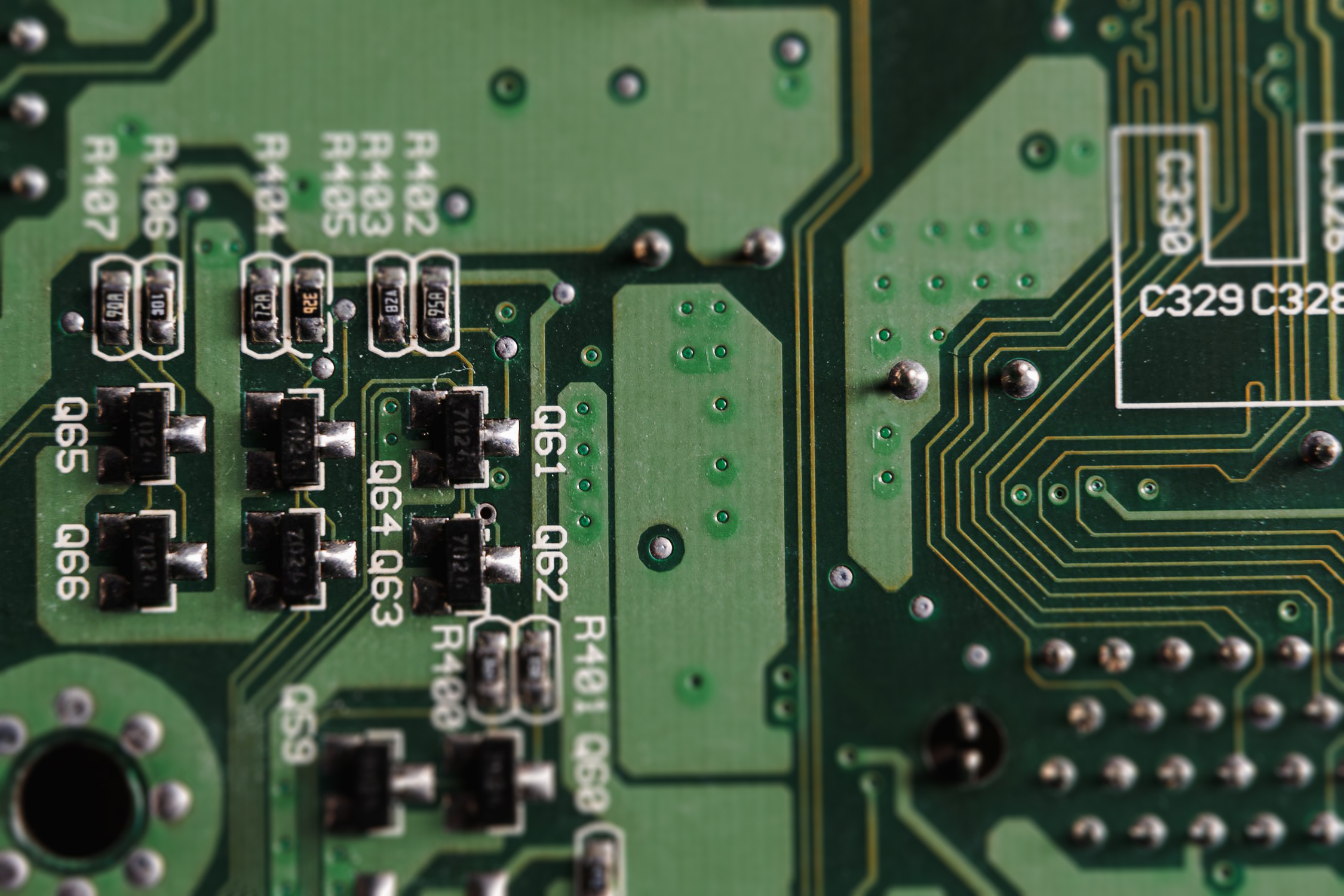

PCB common problems and solutions

(Summary description)①The PCB board is short-circuited. This problem is one of the common faults that directly cause the PCB board to fail to work. There are many reasons for this problem. The biggest cause of PCB short circuit is improper solder pad design. The solution is to change the round solder pad to The oval shape increases the distance between points to prevent short circuits.

Secondly, the improper design of the direction of the PCB parts will also cause the board to short-circuit and fail to work. Therefore, the part orientation can be appropriately modified...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-07-16

- Views:0

①The PCB board is short-circuited. This problem is one of the common faults that directly cause the PCB board to fail to work. There are many reasons for this problem. The biggest cause of PCB short circuit is improper solder pad design. The solution is to change the round solder pad to The oval shape increases the distance between points to prevent short circuits.

Secondly, the improper design of the direction of the PCB parts will also cause the board to short-circuit and fail to work. Therefore, the part orientation can be appropriately modified.

There is another possibility that will cause short circuit failure of the PCB, that is, the automatic plug-in bent foot. As IPC stipulates that the length of the pin is less than 2mm, the solder joint must be more than 2mm away from the circuit. In addition, there are also some reasons that can cause short circuit failures of the PCB board, such as too large a hole in the substrate, too low temperature of the tin furnace, poor solderability of the board, failure of the solder mask, and contamination of the board. More common failure causes, so we must pay special attention to the production process, try to avoid these problems.

② Dark and grainy contacts appear on the PCB board. The problem of dark color or small-grained contacts on the PCB is mostly due to contamination of the solder and excessive oxides mixed in the molten tin. Another reason for this problem is that the composition of the solder used in the manufacturing process has changed, and the impurity content is too high. It is necessary to add pure tin or replace the solder.

③PCB solder joints become golden yellow. Under normal circumstances, the solder on the PCB board is silver gray, but occasionally there are golden solder joints. The main reason for this problem is that the temperature is too high. At this time, you only need to lower the temperature of the tin furnace.

④ Welding problems. Poor welding can lead to short circuits, open circuits, cold solder joints, etc. Therefore, welding quality problems should be strictly controlled during the welding process to avoid product short circuits.

⑤ Loose or misplaced components. Possible reasons for shifting or tilting include insufficient circuit board support, reflow oven settings, solder paste issues, human error, etc.

⑥PCB is open. When the trace is broken, or when the solder is only on the pad and not on the component leads, an open circuit can occur.

⑦The badness of the board is also affected by the environment. Due to the structure of the PCB itself, it is easy to cause damage to the PCB when it is in an unfavorable environment. Extreme temperature or temperature fluctuations, excessive humidity, high-intensity vibration and other conditions are all factors that cause the board's performance to decrease or even scrap. On the other hand, moisture in the air can cause oxidation, corrosion and rust on the metal surface, such as exposed copper traces, solder joints, pads, and component leads. Accumulation of dirt, dust or debris on the surface of components and circuit boards can also reduce the air flow and cooling of the components, causing PCB overheating and performance degradation.

⑧ Human error. Most of the defects in PCB manufacturing are caused by human error. In most cases, the wrong production process, the wrong placement of components and unprofessional manufacturing specifications are the important reasons for the defects of most products.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback