新闻资讯banner

PCBA repair in SMT patch processing.

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-03

- Views:0

(Summary description)Generally speaking, if PCBA has problems in the SMT chip manufacturing process and use process, that is, processing errors, improper use or aging of components, there will be abnormal work or even poor use of the entire PCBA product. But because many products do not need to be completely replaced, certain maintenance of the circuit board is required. How to perform maintenance? The following Sanjing briefly share some circuit board repair technical experience and skills for you, hope it will be helpful to everyone!

Generally, when facing a circuit board that needs to be repaired, our technical maintenance personnel will perform the following operations:...

PCBA repair in SMT patch processing.

(Summary description)Generally speaking, if PCBA has problems in the SMT chip manufacturing process and use process, that is, processing errors, improper use or aging of components, there will be abnormal work or even poor use of the entire PCBA product. But because many products do not need to be completely replaced, certain maintenance of the circuit board is required. How to perform maintenance? The following Sanjing briefly share some circuit board repair technical experience and skills for you, hope it will be helpful to everyone!

Generally, when facing a circuit board that needs to be repaired, our technical maintenance personnel will perform the following operations:...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-03

- Views:0

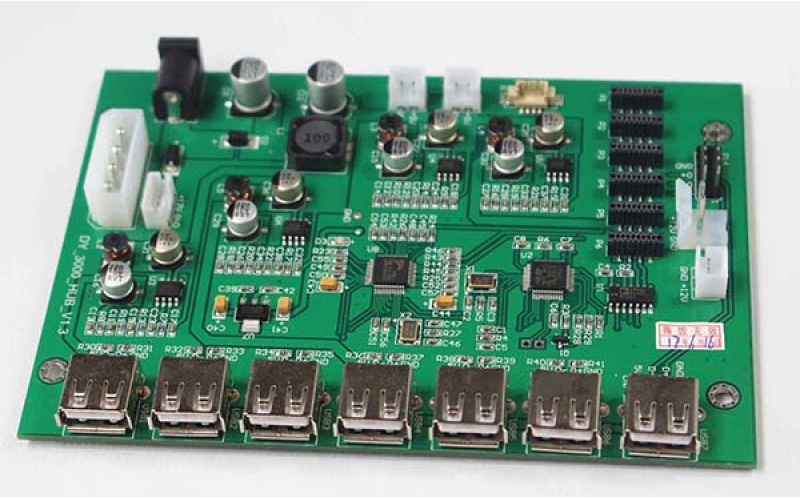

Generally speaking, if PCBA has problems in the SMT chip manufacturing process and use process, that is, processing errors, improper use or aging of components, there will be abnormal work or even poor use of the entire PCBA product. But because many products do not need to be completely replaced, certain maintenance of the circuit board is required. How to perform maintenance? The following Sanjing briefly share some circuit board repair technical experience and skills for you, hope it will be helpful to everyone!

Generally, when facing a circuit board that needs to be repaired, our technical maintenance personnel will perform the following operations:

1. Check the components

Before repairing a faulty circuit board, it is generally necessary to check the components of each solder joint for errors, omissions, and inversions. At the same time, check the authenticity of the materials. After these problems are eliminated, check whether there are obvious signs of burnout on the various components of the circuit board.

2. Analysis of welding status

Under normal circumstances, the cause of defective circuit boards is basically due to poor solder joints. Whether the solder joints are full or abnormal, firstly refer to the management standards of the ISO9001 quality system and various SMT processing welding quality standards to check whether there are any visible defects such as false welding, false welding, short circuit, or obvious lifting of the copper skin. . If so, it is necessary to repair the defective points of the product in time.

3. Detection of component orientation

In this link, we have basically ruled out some defects that are visible to the naked eye, but we still need to carefully observe those that are not clearly visible to the naked eye, such as diodes, electrolytic capacitors and other components on the circuit board with a large amount. If the direction is specified Or components that require positive and negative poles should be checked whether they are inserted in the wrong direction.

4. Tool inspection of components

If the previous problems that we can see with the naked eye are eliminated, we need to use some auxiliary tools to detect. The most commonly used in SMT chip processing plants is to use a multimeter to measure components such as resistors, capacitors, and transistors. The purpose is to check whether the resistance of these components meets the normal value, whether the value is stable (larger or smaller), and whether the capacitor is open. Whether the inductance is open, etc.

5, power test

The last step is to basically eliminate the conventional problems of the components, you can turn on the power for testing. If there is no short circuit or bridging that will cause ablation and damage to the circuit board after power-on, then check whether the corresponding function of the circuit board is normal.

After all the above operation procedures are completed, the technical maintenance personnel can judge and repair the defects of the product based on the customer's BOM, Gerber, and schematic diagrams.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback