新闻资讯banner

Printing solder paste sampling inspection

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-06-08

- Views:0

(Summary description)In the SMT production and processing link, the printing solder paste process plays a very critical role in the SMT assembly quality, so the quality of the printing solder paste must be strictly controlled. Next, Sanjing will share with you how to inspect the printed solder paste.

There are different inspection methods in different situations. For example, when there is a narrow pitch (the lead center distance is less than 065mm), it must be fully inspected. When there is no narrow interval, it can be inspected regularly (such as once every hour), or it can be randomly inspected according to...

Printing solder paste sampling inspection

(Summary description)In the SMT production and processing link, the printing solder paste process plays a very critical role in the SMT assembly quality, so the quality of the printing solder paste must be strictly controlled. Next, Sanjing will share with you how to inspect the printed solder paste.

There are different inspection methods in different situations. For example, when there is a narrow pitch (the lead center distance is less than 065mm), it must be fully inspected. When there is no narrow interval, it can be inspected regularly (such as once every hour), or it can be randomly inspected according to...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-06-08

- Views:0

In the SMT production and processing link, the printing solder paste process plays a very critical role in the SMT assembly quality, so the quality of the printing solder paste must be strictly controlled. Next, Sanjing will share with you how to inspect the printed solder paste.

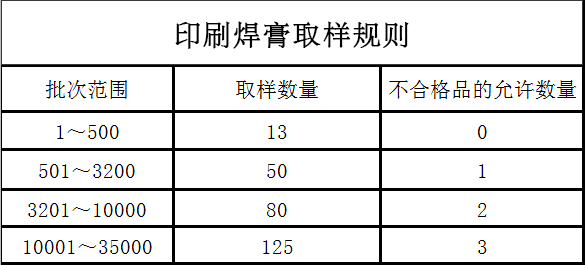

There are different inspection methods in different situations. For example, when there is a narrow pitch (the lead center distance is less than 065mm), it must be fully inspected. When there is no narrow interval, it can be inspected regularly (such as once every hour), or it can be randomly inspected according to the sampling rules shown in the figure below.

What is the specific inspection method? The inspection methods mainly include: visual inspection and solder paste inspection machine inspection.

1. Visual inspection, use a magnifying glass of 2 to 5 times or a microscope of 3.5 to 20 times.

2. Use solder paste inspection machine (SPI) to inspect for narrow pitch.

The solder paste printing process is very unstable compared to other processes in SMT production. According to numerous studies, the maximum amount of change in this process is 60%. This is because the solder paste printing process involves many related process parameters, about 35 parameters need to be controlled, these parameters include solder paste type, environmental conditions (temperature, humidity, etc.), template type (chemical corrosion, laser cutting, laser Cutting and polishing, electroforming), template thickness, opening shape, aspect ratio, area ratio, printer model, squeegee, printing head technology, printing speed, etc. These factors greatly reduce the repeatability of printing.

Generally, the density can be detected by 2DSPI. It can be tested on the whole board or locally. The test points for the whole board test should be selected at the top, bottom, left, right and middle 5 points on the printed surface; local testing is generally used for high-density parts on the board and for BGA, CSP and other devices. For testing, the thickness of solder paste is required to be between -10% and +15% of the thickness of the template.

For narrow-pitch QFP, CSP, 01005, POP and other packages, 3DSPI solder paste inspection machine should be used for inspection.

Finally, no matter what kind of inspection method, it should be carried out according to relevant inspection standards. In addition to strict control over the quality of printed solder paste, all PCBA processes must pay attention to detail control. Only by striving for every step can we welcome customers.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback