新闻资讯banner

SMT processing, modification and replacement of chip components

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-21

- Views:0

(Summary description)We know that chip components are one of the most contacted materials in SMT processing. In SMT processing and repair, we often encounter the situation of replacing chip components. It seems simple to replace chip components, but there are many small tricks. If you don't pay attention, it will be more troublesome to operate. Therefore, in order to ensure product quality, we should strictly follow the relevant standard requirements for replacing chip components. Let’s take a look at the following Sanjing belts:

In the process of SMT processing and rework, we should prepare a grounding wire and temperature-controlled electric soldering iron before replacing chip components. The width of the soldering iron tip and the size of the metal end face of the chip components must be...

SMT processing, modification and replacement of chip components

(Summary description)We know that chip components are one of the most contacted materials in SMT processing. In SMT processing and repair, we often encounter the situation of replacing chip components. It seems simple to replace chip components, but there are many small tricks. If you don't pay attention, it will be more troublesome to operate. Therefore, in order to ensure product quality, we should strictly follow the relevant standard requirements for replacing chip components. Let’s take a look at the following Sanjing belts:

In the process of SMT processing and rework, we should prepare a grounding wire and temperature-controlled electric soldering iron before replacing chip components. The width of the soldering iron tip and the size of the metal end face of the chip components must be...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-21

- Views:0

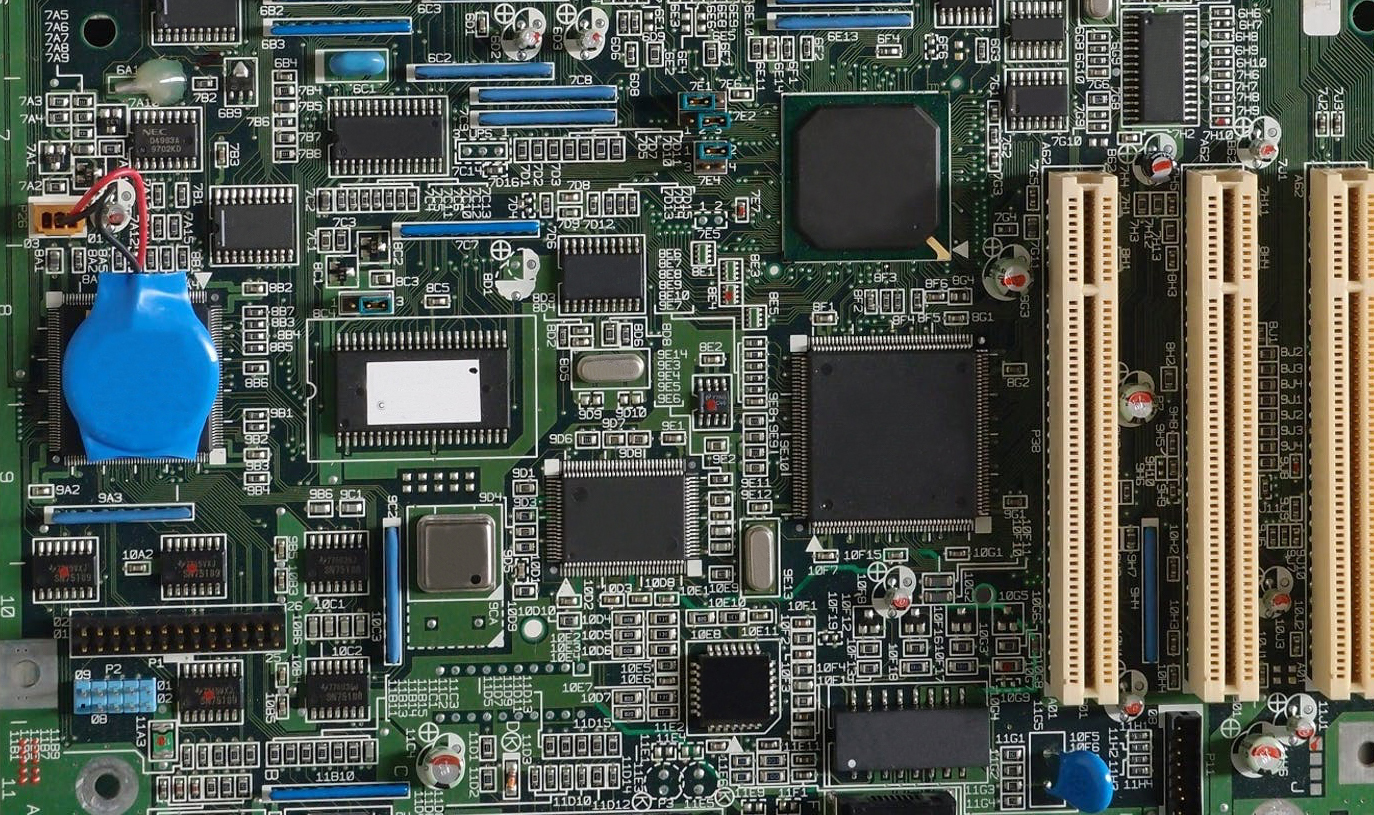

We know that chip components are one of the most contacted materials in SMT processing. In SMT processing and repair, we often encounter the situation of replacing chip components. It seems simple to replace chip components, but there are many small tricks. If you don't pay attention, it will be more troublesome to operate. Therefore, in order to ensure product quality, we should strictly follow the relevant standard requirements for replacing chip components. Let’s take a look at the following Sanjing belts:

In the process of SMT processing and rework, we should prepare a grounding wire and temperature-controlled electric soldering iron before replacing chip components. The width of the soldering iron tip and the size of the metal end face of the chip components must be in line with the temperature of the soldering iron. At 320°C, in addition to the electric soldering iron, you also need to prepare basic tools such as tweezers, tin bars, fine low-temperature rosin, and welding wire. When all the tools that need to be used are ready, the replacement work can be carried out.

When replacing chip components, you can directly put the heated soldering iron tip on the upper surface of the damaged component, and then wait until the solder on both sides of the chip component and the adhesive under the component are melted at high temperature, you can use tweezers to directly Remove the damaged component. After removing the damaged component, you need to clean the tin remaining on the circuit board with a tin removal strip, and then use alcohol to scrub the adhesive and other stains on the original pad.

When PCBA is processed, usually only one side of the circuit board will burn a proper amount of solder, and then use tweezers to place the component on the pad. In order to quickly heat the tin on the pad, it is necessary to place the molten tin contact chip component on the metal end. But one thing to note is that the tip of the soldering iron should not directly touch the component.

Under normal circumstances, as long as one end of the newly replaced chip component is fixed, the other end can be welded. The pad on the circuit board needs to be heated and an appropriate amount of solder should be added to make the pad and the component end form a bright arc. It should be noted that the amount of solder cannot be placed too much, otherwise the molten solder will flow under the component and cause soldering. The disk is short-circuited. Like the other end of the soldering pad, only the molten tin can be dipped into the metal end surface of the component, and the soldering iron tip should not touch the component, thus completing the entire replacement process.

The above is about the method of SMT processing, repair and replacement of chip components, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback