新闻资讯banner

The basic operation process of SMT processing template printing

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-03

- Views:0

(Summary description)SMT processing template printing is the most basic solder paste printing method for SMT processing plants. Nowadays, there are many kinds of printing equipment and printing methods on the market, but they are invariably invariable, and the printing process is basically the same. The following Sanjing briefly introduces the basic operation flow of SMT processing template printing.

The first one is preparation before printing. Before printing, we generally have to prepare the required documents, materials and fixtures. The documents mainly include assembly technical documents, process cards and precautions; materials mainly include solder paste, PCB boards to be printed, alcohol, wipe paper, etc.; fixtures mainly include templates, scrapers, tools, etc.

When all the preparations before printing are done, the second step, template and squeegee installation can be carried out. The template installation is mainly to insert the template into the template track and push it to the final position to fix it...

The basic operation process of SMT processing template printing

(Summary description)SMT processing template printing is the most basic solder paste printing method for SMT processing plants. Nowadays, there are many kinds of printing equipment and printing methods on the market, but they are invariably invariable, and the printing process is basically the same. The following Sanjing briefly introduces the basic operation flow of SMT processing template printing.

The first one is preparation before printing. Before printing, we generally have to prepare the required documents, materials and fixtures. The documents mainly include assembly technical documents, process cards and precautions; materials mainly include solder paste, PCB boards to be printed, alcohol, wipe paper, etc.; fixtures mainly include templates, scrapers, tools, etc.

When all the preparations before printing are done, the second step, template and squeegee installation can be carried out. The template installation is mainly to insert the template into the template track and push it to the final position to fix it...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-03

- Views:0

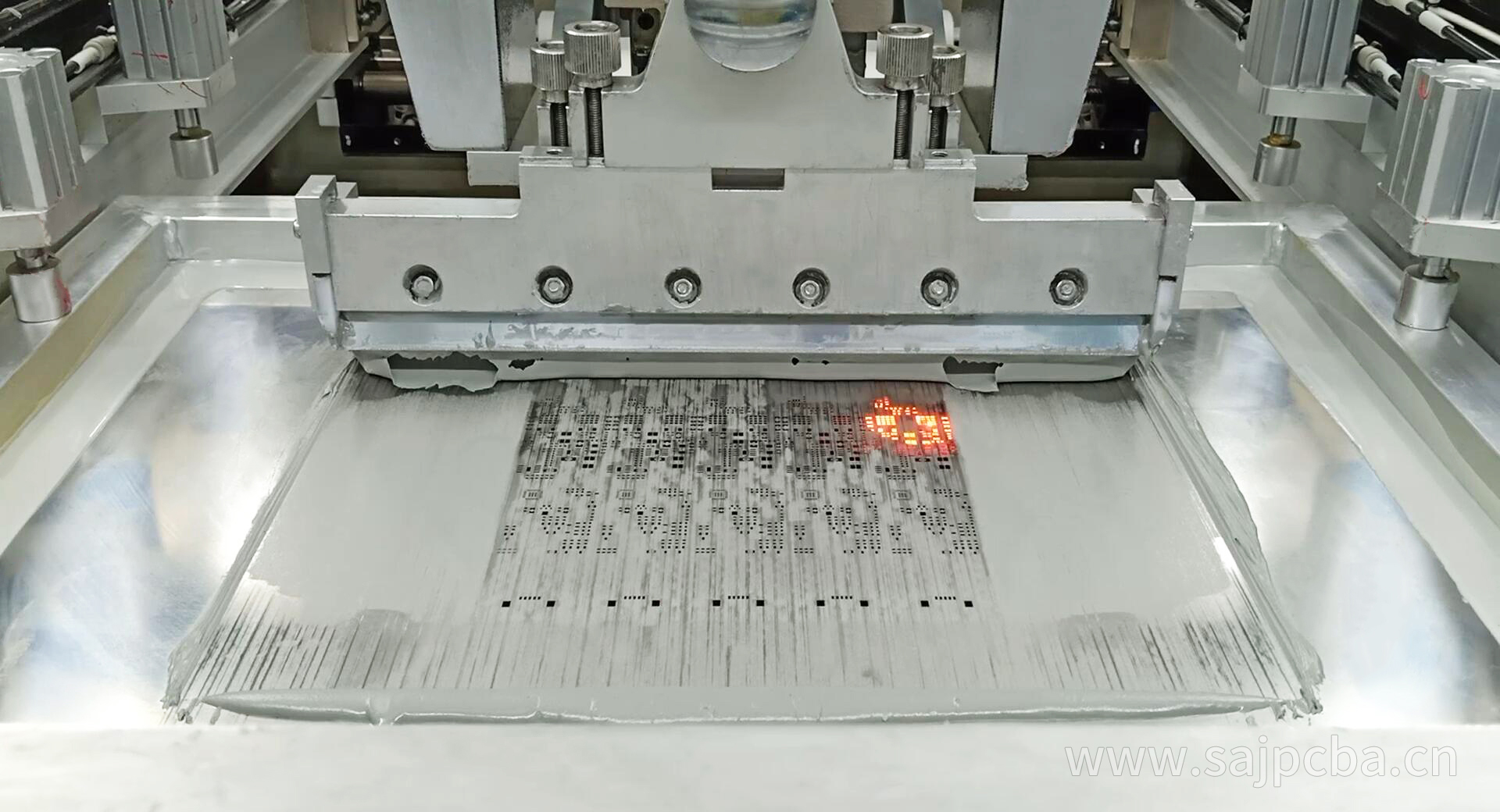

SMT processing template printing is the most basic solder paste printing method for SMT processing plants. Nowadays, there are many kinds of printing equipment and printing methods on the market, but they are invariably invariable, and the printing process is basically the same. The following Sanjing briefly introduces the basic operation flow of SMT processing template printing.

The first one is preparation before printing. Before printing, we generally have to prepare the required documents, materials and fixtures. The documents mainly include assembly technical documents, process cards and precautions; materials mainly include solder paste, PCB boards to be printed, alcohol, wipe paper, etc.; fixtures mainly include templates, scrapers, tools, etc.

When all the preparations before printing are done, the second step, template and squeegee installation can be carried out. The template installation is mainly to insert the template into the template track and push it to the final position to fix it. The installation of the scraper is to select the appropriate scraper according to the needs of the production process of the product to be assembled. Generally, a stainless steel scraper is selected. When high-density assembly is used, trailing scrapers are generally selected for installation.

After the template and squeegee are installed, you need to align the PCB positioning with the graphics. The reason for positioning the PCB is to initially adjust the substrate to the position corresponding to the template image. There are also many ways to position the substrate, such as hole positioning, edge positioning, vacuum positioning, and so on. Here, by the way, Sanjing briefly introduces several positioning methods. Hole positioning: semi-automatic equipment, vision system is required when higher accuracy is required, and special positioning posts are required. Edge positioning: Fully automatic equipment, requiring optical positioning, and high substrate thickness and flatness requirements. Vacuum positioning: Use vacuum suction to ensure printing quality.

After the PCB is aligned with the graphics, the relevant process parameters can be set, such as squeegee selection, squeegee pressure, squeegee speed and angle; separation speed, printing gap, printing stroke, cleaning mode and frequency, etc.

After the process parameters are set, solder paste can be added for printing. Adding solder paste generally uses a small squeegee to apply the solder paste evenly along the width of the squeegee behind the stencil's missing pattern. It should be noted here that solder paste cannot be applied to the stencil's leakage hole.

After the printing is completed, it is necessary to analyze the results of the stencil printing. The standard for qualified solder paste printing is: the amount of solder paste is uniform and consistent; the solder paste pattern is clear, and the adjacent patterns have no adhesion; the solder paste pattern and the land pattern have no misalignment, etc.

The last step is to analyze the solder paste defects to avoid solder paste defects when printing again.

The above is about the basic operation process of SMT processing stencil printing, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback