新闻资讯banner

The design and requirements of the minimum spacing of SMT components

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-03

- Views:0

(Summary description)With the rapid development of the electronics industry, SMT chip processing is gradually developing in the direction of high precision and fine pitch. At the same time, the minimum pitch design of components can also test whether the production technology and process experience of SMT manufacturers are perfect. In addition to ensuring a safe distance between SMT pads that is not easy to short in the design of the minimum spacing of components, the maintainability of the components should also be considered.

However, there are many factors related to the spacing of components. Let us understand the following Sanjing:

①Tolerance of the external dimensions of the components and the heat released by the components. ②The rotation speed and positioning accuracy of the placement machine. ③The number of PCB layers used is known, and the space required for wiring design...

The design and requirements of the minimum spacing of SMT components

(Summary description)With the rapid development of the electronics industry, SMT chip processing is gradually developing in the direction of high precision and fine pitch. At the same time, the minimum pitch design of components can also test whether the production technology and process experience of SMT manufacturers are perfect. In addition to ensuring a safe distance between SMT pads that is not easy to short in the design of the minimum spacing of components, the maintainability of the components should also be considered.

However, there are many factors related to the spacing of components. Let us understand the following Sanjing:

①Tolerance of the external dimensions of the components and the heat released by the components. ②The rotation speed and positioning accuracy of the placement machine. ③The number of PCB layers used is known, and the space required for wiring design...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-03

- Views:0

With the rapid development of the electronics industry, SMT chip processing is gradually developing in the direction of high precision and fine pitch. At the same time, the minimum pitch design of components can also test whether the production technology and process experience of SMT manufacturers are perfect. In addition to ensuring a safe distance between SMT pads that is not easy to short in the design of the minimum spacing of components, the maintainability of the components should also be considered.

However, there are many factors related to the spacing of components. Let us understand the following Sanjing:

①Tolerance of the external dimensions of the components and the heat released by the components. ②The rotation speed and positioning accuracy of the placement machine. ③The number of PCB layers used is known, and the space required for wiring design is known. ④ Welding processability and naked eye testability of solder joints. ⑤Gap required for automatic plug-in machine. ⑥ The use of test fixtures. ⑦Access for assembly and repair.

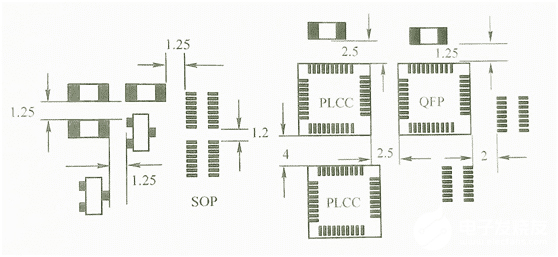

(1) The minimum spacing between surface mount components of general SMT patch density is shown in the figure below:

①The distance between chip components, SOT, SOIC and chip components is 1.25mm.

② Between SOIC and between SOIC and QFP is 2mm.

③The distance between PLCC and chip components, SOIC and QFP is 2.5mm.

④The distance between PLCC is 4mm.

⑤When designing a PLCC socket, pay attention to the size of the PLCC socket (PLCC pins are located inside the bottom of the socket).

(2) The minimum distance between SMC/SMD and through-hole components: When mixing SMT patches, the minimum distance between SMC/SMD and through-hole components is determined according to the package size of the through-hole components. The main consideration is the shape of the package body and the height of the component body. The minimum distance between the interposing component and the chip component is generally above 1.27mm.

(3) Pad spacing for high-density PCB assembly: At present, the pad spacing of 0210PCB is generally 1.5mm, and the minimum spacing is 0.1mm; the minimum spacing of 01005 pads is 0.08mm.

The above is about the minimum spacing design and requirements of SMT components, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback