新闻资讯banner

Types of residues on PCBA

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-09-08

- Views:0

(Summary description)With the development of the electronic information industry, PCBA assembly process requirements are getting higher and higher, and the quality and reliability of electronic products depend on the quality and reliability of PCBA. However, from the process practice and PCBA failure analysis, it is known that the quality and reliability of PCBA are also affected by many factors, such as welding residue. The following Sanjing will introduce you:

During the soldering process, the residues are generally flux residues, by-products of the reaction between flux and solder, adhesives, lubricating oil, etc., or other relatively small potential hazards such as contaminants carried in the production and transportation of PCB components. These residues are generally divided into three types: one is non-polar residues, mainly including rosin, resin, adhesives, lubricating oil, etc. These residues are generally cleaned with non-polar cleaning solvents to be better removed; the second type It is a polar residue, also called an ionic residue, which mainly...

Types of residues on PCBA

(Summary description)With the development of the electronic information industry, PCBA assembly process requirements are getting higher and higher, and the quality and reliability of electronic products depend on the quality and reliability of PCBA. However, from the process practice and PCBA failure analysis, it is known that the quality and reliability of PCBA are also affected by many factors, such as welding residue. The following Sanjing will introduce you:

During the soldering process, the residues are generally flux residues, by-products of the reaction between flux and solder, adhesives, lubricating oil, etc., or other relatively small potential hazards such as contaminants carried in the production and transportation of PCB components. These residues are generally divided into three types: one is non-polar residues, mainly including rosin, resin, adhesives, lubricating oil, etc. These residues are generally cleaned with non-polar cleaning solvents to be better removed; the second type It is a polar residue, also called an ionic residue, which mainly...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-09-08

- Views:0

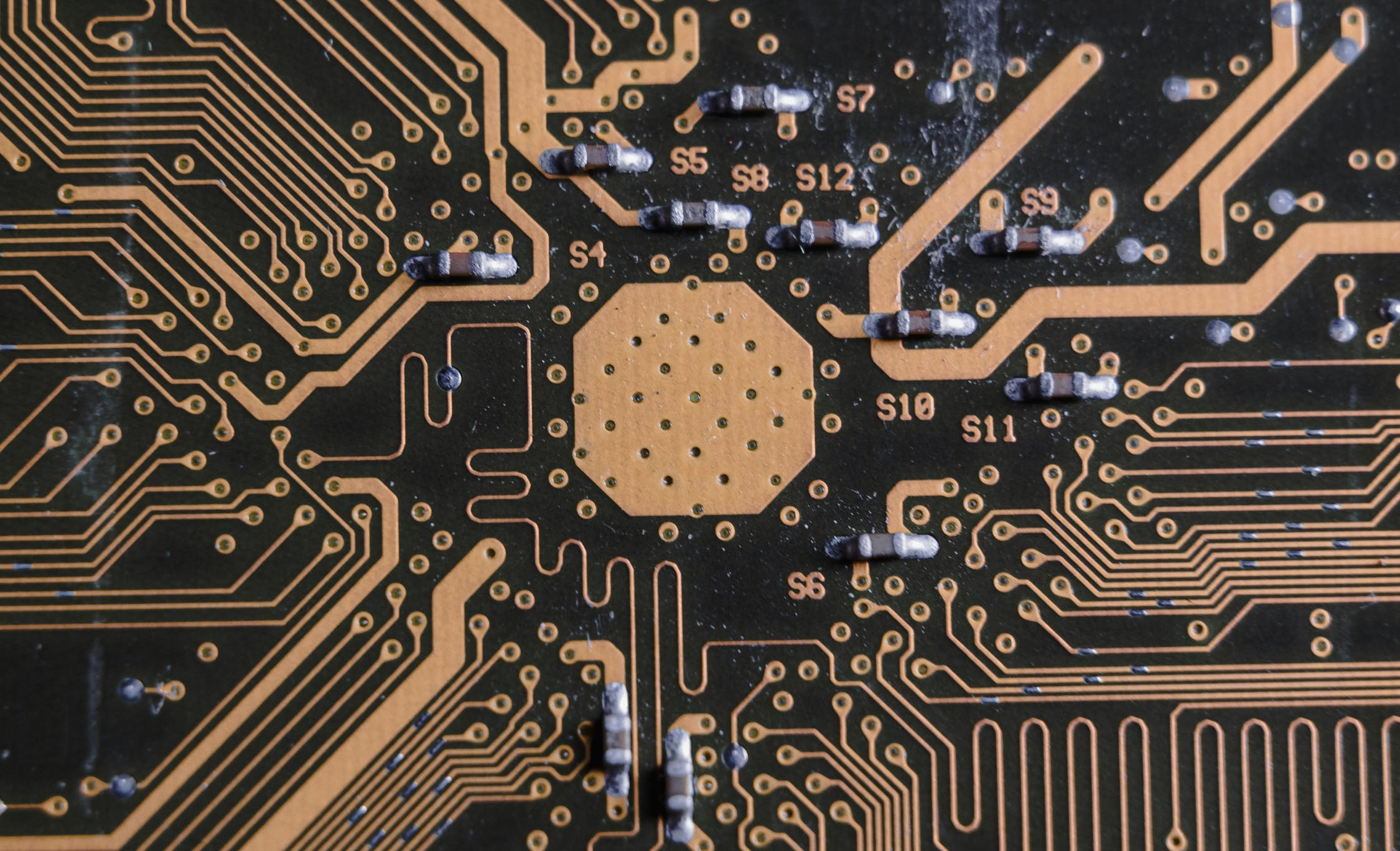

With the development of the electronic information industry, PCBA assembly process requirements are getting higher and higher, and the quality and reliability of electronic products depend on the quality and reliability of PCBA. However, from the process practice and PCBA failure analysis, it is known that the quality and reliability of PCBA are also affected by many factors, such as welding residue. The following Sanjing will introduce you:

During the soldering process, the residues are generally flux residues, by-products of the reaction between flux and solder, adhesives, lubricating oil, etc., or other relatively small potential hazards such as contaminants carried in the production and transportation of PCB components. These residues are generally divided into three types: one is non-polar residues, mainly including rosin, resin, adhesives, lubricating oil, etc. These residues are generally cleaned with non-polar cleaning solvents to be better removed; the second type It is a polar residue, also called an ionic residue, which mainly includes active substances in the flux, such as halogen ions, and salts produced by various reactions. If you want to remove it well, you need to clean it with a polar solvent, such as water. , Methanol, there is also a weakly polar residue (organic acid and alkali) from the flux. If you want to remove it well, you need to use a composite solvent. The different types of residues are introduced below:

(1) Rosin flux residue: The flux containing rosin or modified resin is mainly composed of non-polar rosin resin and a small amount of halide, organic acid and organic solvent carrier. Organic solvents will be volatilized and removed due to high temperature during the process. Active substances such as halide organic acids (such as adipic acid) mainly remove the oxide layer on the welded surface and improve the welding effect.

(2) Organic acid flux residues: Organic acid flux (OA) generally means that the solid part of the flux is mainly organic acid. This type of flux residue is mainly unreacted organic acids, such as oxalic acid and succinic acid. And metal salts, etc. Most of the colorless no-clean fluxes on the market are mainly composed of polybasic organic acids, including halogen-free ions at room temperature, halide ions will be generated when soldering at high temperatures, and sometimes a small amount of polar resins. The most of these residues What is difficult to remove is the salt formed by organic acid and solder, which has strong adsorption capacity and poor solubility. When water-soluble flux is used, a large amount of residues and halide salts will be produced. Due to timely water-based cleaning, the residues can be greatly reduced.

(3) White residue: Generally, it is a by-product of flux. If the PCB quality is poor (such as the solder mask is too adsorbed), it will increase the possibility of white residue. Common white residues are polymerized rosin, unreacted activator, and the reaction of flux and solder to produce lead chloride or bromide, etc. These substances expand in volume after absorbing moisture, and some substances also undergo hydration reaction with water. The white residue is more obvious. Natural rosin is prone to a large number of polymerization reactions during the welding process. If the high temperature time is too long, the problem will be more serious.

(4) Adhesive and oil pollution: In the PCBA assembly process, some glue is often used to fix the components. In many cases, improper operation will stick to the electrical connection part. At the same time, the residue after the pad protection tape is torn off will seriously affect the electrical connection. 接 performance. In addition, if too much lubricant is applied to small components, it will also contaminate the PCBA surface.

The above is about the types of residues on PCBA, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback