新闻资讯banner

What are the basic elements of SMT assembly

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-11-16

- Views:0

(Summary description)SMT is the abbreviation of surface mount technology, a PCB assembly technology, which refers to the technology of soldering components directly to the surface of the PCB to replace THT, which requires the use of drilling. When SMT assembly is used in electronic manufacturing, components with short or no leads (SMC/SMD) are placed on the corresponding position on the circuit board or substrate, and then reflow soldering or wave soldering is used to permanently fix the component on the board.

(1) SMT attributes

①Miniaturization: SMC/SMD has the characteristics of light weight, small size and high installation accuracy. Therefore, the volume of the final product using SMT can be reduced by 40% to 60%, and the weight can be reduced by 60% to 80%. ②High performance: The components in the SMT assembly have a low rejection rate and higher vibration resistance. ③High reliability: Electronic products using SMT components have high frequencies...

What are the basic elements of SMT assembly

(Summary description)SMT is the abbreviation of surface mount technology, a PCB assembly technology, which refers to the technology of soldering components directly to the surface of the PCB to replace THT, which requires the use of drilling. When SMT assembly is used in electronic manufacturing, components with short or no leads (SMC/SMD) are placed on the corresponding position on the circuit board or substrate, and then reflow soldering or wave soldering is used to permanently fix the component on the board.

(1) SMT attributes

①Miniaturization: SMC/SMD has the characteristics of light weight, small size and high installation accuracy. Therefore, the volume of the final product using SMT can be reduced by 40% to 60%, and the weight can be reduced by 60% to 80%. ②High performance: The components in the SMT assembly have a low rejection rate and higher vibration resistance. ③High reliability: Electronic products using SMT components have high frequencies...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-11-16

- Views:0

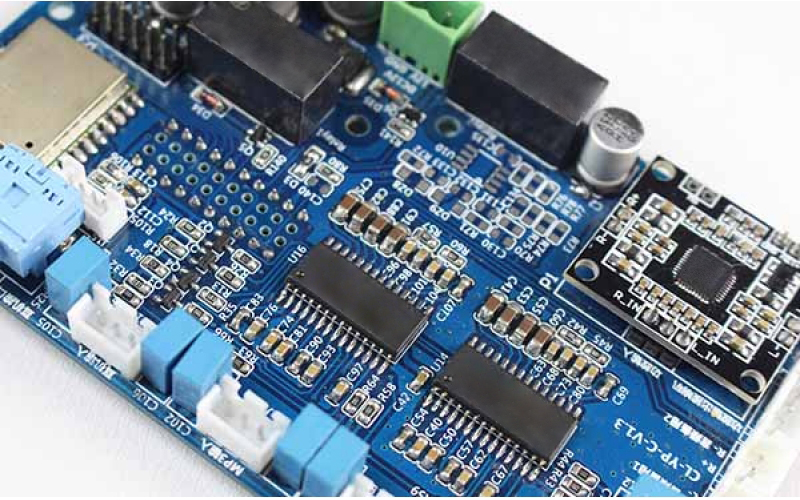

SMT is the abbreviation of surface mount technology, a PCB assembly technology, which refers to the technology of soldering components directly to the surface of the PCB to replace THT, which requires the use of drilling. When SMT assembly is used in electronic manufacturing, components with short or no leads (SMC/SMD) are placed on the corresponding position on the circuit board or substrate, and then reflow soldering or wave soldering is used to permanently fix the component on the board.

(1) SMT attributes

①Miniaturization: SMC/SMD has the characteristics of light weight, small size and high installation accuracy. Therefore, the volume of the final product using SMT can be reduced by 40% to 60%, and the weight can be reduced by 60% to 80%. ②High performance: The components in the SMT assembly have a low rejection rate and higher vibration resistance. ③High reliability: Electronic products using SMT components have high frequencies, and electromagnetic interference (EMI) and radio frequency interference (RF) are reduced. ④High efficiency: SMT assembly automation has high production efficiency.

Compared with THT assembly, THT assembly is gradually replaced by SMT assembly because THT cannot meet the current miniaturized electronic requirements in terms of the volume of electronic products.

(2) SMT assembly procedure steps: solder paste printing, chip mounting, reflow soldering and inspection. The materials used in SMT assembly include solder paste, flux, adhesives, cleaning agents, heat transfer media, etc.

①Solder paste: The solder paste in the SMT assembly process acts as a solder and an adhesive to fix the SMC/SMD to the PCB surface. The main elements of the solder paste, Sn63/Pb37 and Sn62/Pb36/Ag2, have comprehensive properties.

②Flux: It plays a role in assisting the smooth progress of welding in the SMT assembly process. Flux is divided into acid flux and resin flux, which play a role in eliminating oxides and dirt on the metal surface and wetting of the metal surface.

③Adhesive: Fix the SMD in the SMT assembly to prevent the SMD from shifting or falling off.

④Cleaning agent: used to remove the residue of solder paste remaining on the board. The cleaning agent should have good chemical properties and thermal stability, not easy to decompose during storage and use, and not chemically react with other chemical substances.

(3) SMC/SMD mounting technology: SMC refers to surface mount components, while SMD refers to surface mount devices. When choosing a placement machine, the installation accuracy and speed should be carefully considered. Among them, factors such as X/Y axis structure, X/Y axis movement error, X/Y axis detection, and vacuum nozzle Z axis movement will affect the movement of the placement machine.

(4) Electrostatic discharge (ESD): Electrostatic electricity has a certain randomness, and not all electronic products will be damaged. In addition, the energy of electrostatic charging is mostly very low, and electronic products damaged by static electricity will not immediately cause problems. Therefore, electrostatic protection measures should be carried out in the manufacturing workshop, wear an anti-static wrist strap and gloves, and conduct regular inspections.

The above is about the basic elements of SMT assembly, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback