新闻资讯banner

What are the disassembly methods and techniques for SMT patch components

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-08-21

- Views:0

(Summary description)The disassembly method of SMT chip components is related to its own characteristics. For components with few pins, such as resistors, capacitors, diodes and triodes, when disassembling, you only need to use a soldering iron to heat both ends of the component pins at the same time. The component can be removed with a single lift. For SMD components with more component pins and wider spacing, the same method is used, but it is more convenient to disassemble such components using a hot air gun to melt tin.

In addition to the above disassembly of components by melting tin, there are many ways to disassemble the components. The following Sanjing will introduce for everyone.

① Dedicated soldering iron tip removal method. The "N"-shaped soldering iron tip can be used to melt the lead pin solder...

What are the disassembly methods and techniques for SMT patch components

(Summary description)The disassembly method of SMT chip components is related to its own characteristics. For components with few pins, such as resistors, capacitors, diodes and triodes, when disassembling, you only need to use a soldering iron to heat both ends of the component pins at the same time. The component can be removed with a single lift. For SMD components with more component pins and wider spacing, the same method is used, but it is more convenient to disassemble such components using a hot air gun to melt tin.

In addition to the above disassembly of components by melting tin, there are many ways to disassemble the components. The following Sanjing will introduce for everyone.

① Dedicated soldering iron tip removal method. The "N"-shaped soldering iron tip can be used to melt the lead pin solder...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-08-21

- Views:0

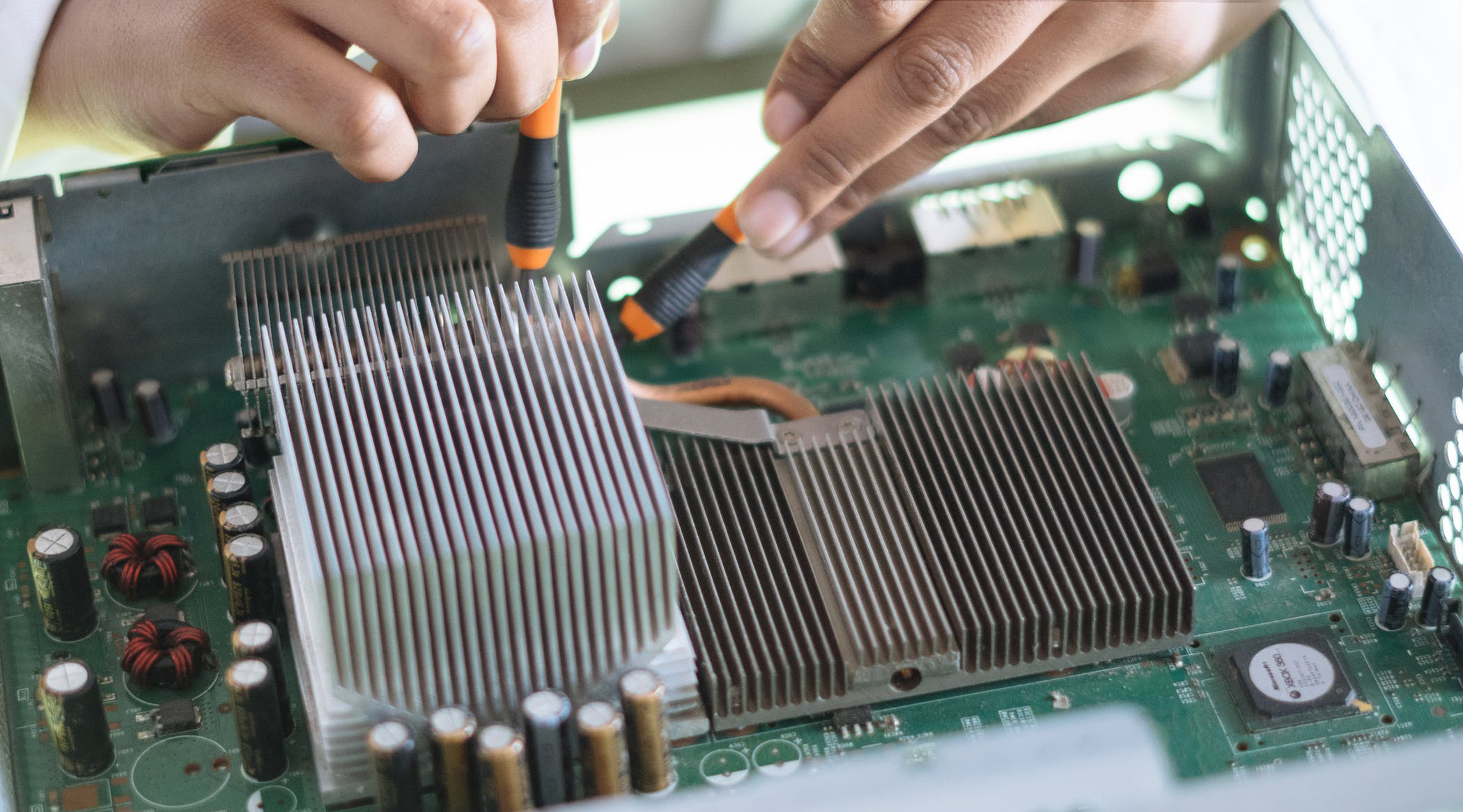

The disassembly method of SMT chip components is related to its own characteristics. For components with few pins, such as resistors, capacitors, diodes and triodes, when disassembling, you only need to use a soldering iron to heat both ends of the component pins at the same time. The component can be removed with a single lift. For SMD components with more component pins and wider spacing, the same method is used, but it is more convenient to disassemble such components using a hot air gun to melt tin.

In addition to the above disassembly of components by melting tin, there are many ways to disassemble the components. The following Sanjing will introduce for everyone.

① Dedicated soldering iron tip removal method. The "N"-shaped soldering iron tip can be used to melt the lead pin solder on both sides of the removed part at the same time, which is convenient for removing the removed components.

② Tin-absorbing copper mesh method. The tin-absorbing copper mesh is made of thin copper wires woven into a mesh belt, which can be replaced by metal shielded wires or multi-strand flexible wires of cable wires. When in use, cover the network cable on the multiple pins, apply rosin alcohol flux, heat it with a soldering iron, and pull the network cable, the solder on each leg will be absorbed by the network cable. Then cut off the network cable that has been soldered, and repeat the heating and sucking tin several times, the solder on the pins gradually decreases, and finally the component pins are separated from the printed board.

③Molten tin cleaning method. When the multi-pin component is heated with an anti-static soldering iron to melt the solder, the solder can be cleaned with a paint brush, and the component can be quickly removed. Note: After removing the components, the printed board should be cleaned in time to prevent residual tin from causing short circuits in other parts.

④The method of removing the solder suction device. There are two types of solder suckers: ordinary solder suckers and electric soldering irons. When the ordinary solder sucker is used, press down the piston rod of the solder sucker. When the soldering point of the disassembled part is melted by the electric soldering iron, put the suction nozzle of the solder sucker close to the melting point, press the button of the solder sucker, and the piston of the solder sucker The rod bounces back to suck away the molten tin. Repeat several times to separate the disassembled parts from the printed board. The soldering iron is a special suction tool that combines an ordinary solder sucker and an electric soldering iron. Its usage is the same as that of an ordinary solder sucker. However, it should be noted that it must be anti-static during the local heating process. The power of the electric soldering iron is The size of the soldering iron tip should be appropriate.

The above is about the disassembly method of SMT patch components, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback