新闻资讯banner

What are the factors that affect the effect of SMT bonding

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-24

- Views:0

(Summary description)We know that for the bonding of SMT surface mount components, many factors will affect the bonding effect. Let us understand the following Sanjing:

The first one is the influence of SMD components. SMD usually uses epoxy resin as the shell, and some glass ceramics and aluminum materials are also used. However, the adhesion of ceramic and glass diodes is usually relatively low, and the adhesion of epoxy resin is better, so the problem of adhesion will not be considered when designing SMD.

The second is PCB influence. The PCB is usually a reinforced glass fiber epoxy board with copper wires and pads on it. Generally, there is no essential difference in surface roughness between a PCB and a PCB with a soldering protective film...

What are the factors that affect the effect of SMT bonding

(Summary description)We know that for the bonding of SMT surface mount components, many factors will affect the bonding effect. Let us understand the following Sanjing:

The first one is the influence of SMD components. SMD usually uses epoxy resin as the shell, and some glass ceramics and aluminum materials are also used. However, the adhesion of ceramic and glass diodes is usually relatively low, and the adhesion of epoxy resin is better, so the problem of adhesion will not be considered when designing SMD.

The second is PCB influence. The PCB is usually a reinforced glass fiber epoxy board with copper wires and pads on it. Generally, there is no essential difference in surface roughness between a PCB and a PCB with a soldering protective film...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-24

- Views:0

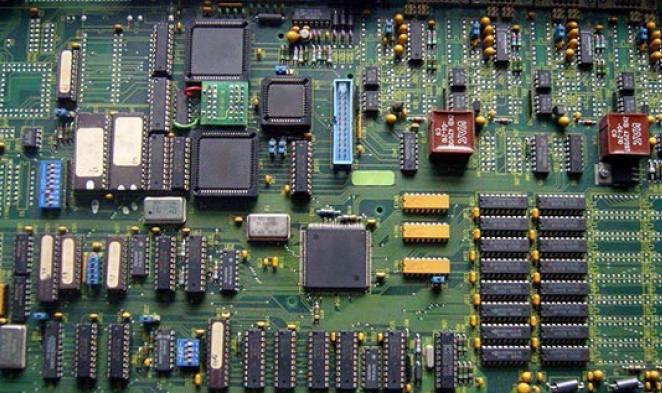

We know that for the bonding of SMT surface mount components, many factors will affect the bonding effect. Let us understand the following Sanjing:

The first one is the influence of SMD components. SMD usually uses epoxy resin as the shell, and some glass ceramics and aluminum materials are also used. However, the adhesion of ceramic and glass diodes is usually relatively low, and the adhesion of epoxy resin is better, so the problem of adhesion will not be considered when designing SMD.

The second is PCB influence. The PCB is usually a reinforced glass fiber epoxy board with copper wires and pads on it. Generally, there is no essential difference in surface roughness between a PCB and a PCB with a soldering protective film.

On PCBs with soldering protective films, bonding is performed on the protective film. When testing the bonding strength, the protective film will be destroyed first. Under normal circumstances, the adhesion of the protective film is not a problem, but if the protective film is contaminated before it is bonded, or some areas are not cured well, it may cause insufficient bonding strength.

The third is the amount of glue used. The amount of glue required for bonding is also determined by many factors, so it is necessary to adjust the amount of glue frequently. In addition, the strength of the bonding and the ability to resist wave soldering are often determined by the strength of the bonding agent and the bonding area.

The above is about the factors that affect the effect of SMT bonding, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback