新闻资讯banner

What are the quality inspection requirements for SMT patch processing

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-08-13

- Views:0

(Summary description)In our daily life, we believe that quality inspection is indispensable in any industry, and the popular meaning of quality inspection is to check the quality of the product. If the quality inspection fails, it means that the product quality is not up to standard.

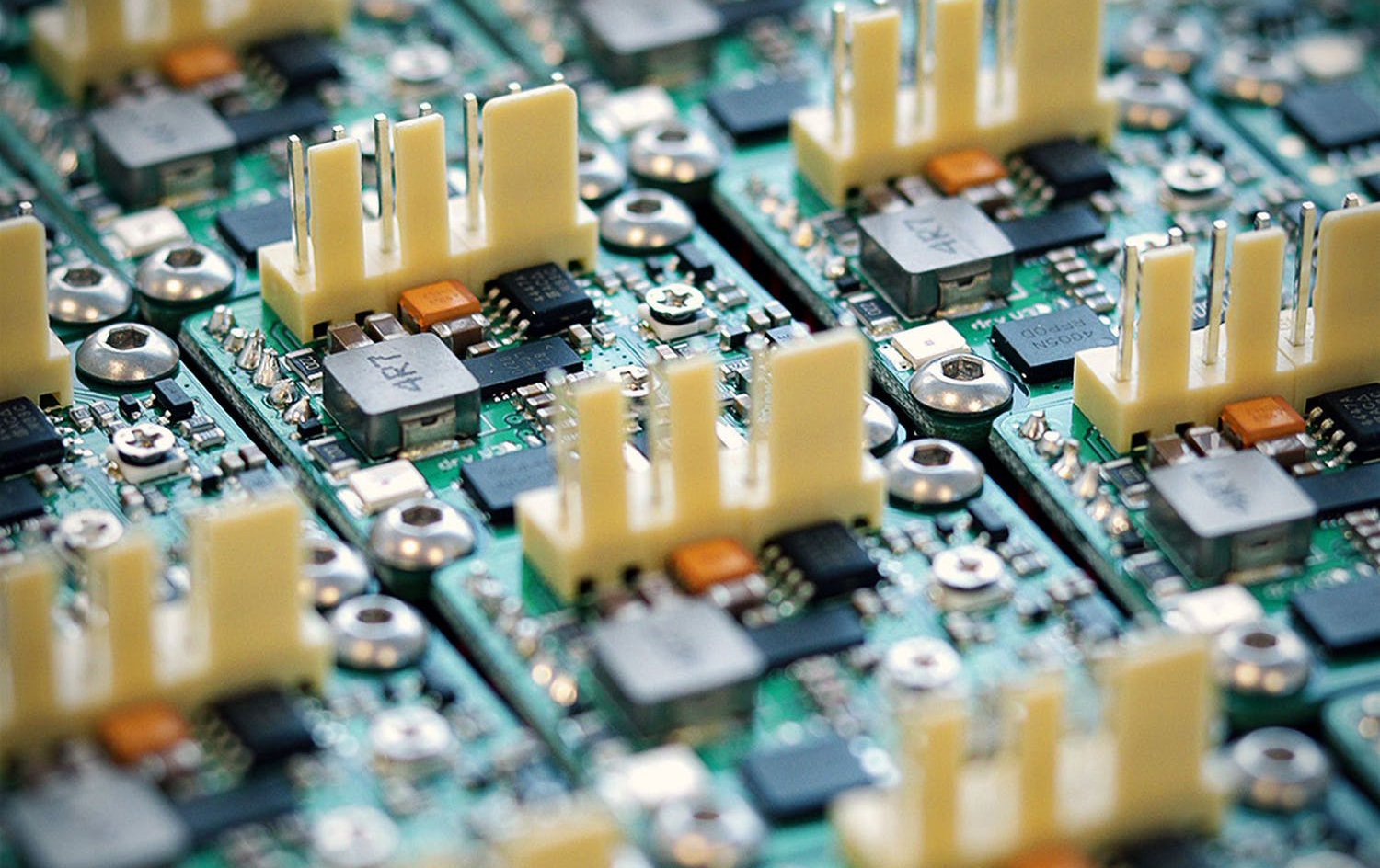

Generally speaking, SMT chip processing quality inspection is relatively strict, because only through strict quality inspection can the quality of SMT processed products be guaranteed to be stable and reliable. However, different products have different quality inspection requirements. The following Sanjing mainly introduces the quality inspection requirements of SMT chip processing.

First, the first one is to inspect the appearance craftsmanship. The inspection requirements for the appearance process are...

What are the quality inspection requirements for SMT patch processing

(Summary description)In our daily life, we believe that quality inspection is indispensable in any industry, and the popular meaning of quality inspection is to check the quality of the product. If the quality inspection fails, it means that the product quality is not up to standard.

Generally speaking, SMT chip processing quality inspection is relatively strict, because only through strict quality inspection can the quality of SMT processed products be guaranteed to be stable and reliable. However, different products have different quality inspection requirements. The following Sanjing mainly introduces the quality inspection requirements of SMT chip processing.

First, the first one is to inspect the appearance craftsmanship. The inspection requirements for the appearance process are...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-08-13

- Views:0

In our daily life, we believe that quality inspection is indispensable in any industry, and the popular meaning of quality inspection is to check the quality of the product. If the quality inspection fails, it means that the product quality is not up to standard.

Generally speaking, SMT chip processing quality inspection is relatively strict, because only through strict quality inspection can the quality of SMT processed products be guaranteed to be stable and reliable. However, different products have different quality inspection requirements. The following Sanjing mainly introduces the quality inspection requirements of SMT chip processing.

First, the first one is to inspect the appearance craftsmanship. The inspection requirements for the appearance process are: ①The circuit board is parallel to the plane, and the board has no protrusions and deformations and no expansion and blistering on the outer surface; ②No cracks or cuts on the board surface, board bottom, copper foil, circuit, through-hole, etc. Short-circuit phenomenon caused by poor cutting; ③No ambiguity, offset, reverse printing, printing deviation, ghosting, etc. of the marked information characters; ④The aperture size of the circuit board meets the requirements of professional SMT design.

Secondly, check the placement process. The inspection requirements for the placement process are: ①SMT components are placed neatly, without offset, skewing, and no reverse paste phenomenon; ②The component models and specifications are correct, and there is no missing or wrong paste; ③There is a polarity requirement SMD components must be installed in accordance with the correct polarity markings.

Third, check the soldering process. The inspection requirements for the soldering process are: ①The surface of the circuit board should have no solder paste foreign matter or traces that affect the appearance; ②The bonding position of the components should have no solder foreign matter, rosin or flux that affects the appearance; ③The tin spots under the components should be well formed , No abnormal wire drawing or sharpening.

The last one is to test the printing process. The inspection requirements for the printing process are: ①The position of the tin paste is centered, without obvious deviation, and does not affect the paste or soldering; ②The amount of the printed tin paste is moderate, and there is no phenomenon of too much tin or too much tin to ensure a good paste; ③Tin The paste point is well formed, with no continuous tin and uneven shape.

In addition to the above basic testing requirements, there are many details that need to be tested. Today, Sanjing will introduce you here, and I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback