新闻资讯banner

What are the requirements of SMT production equipment for PCB

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-07

- Views:0

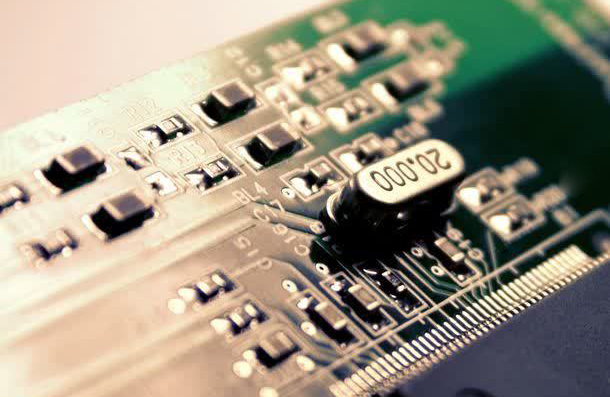

(Summary description)When designing a PCB, the first consideration is the shape of the PCB. When the size of the PCB is too large, the printed lines will increase, resulting in increased impedance and reduced noise immunity, and the cost will increase accordingly; if the size is too small, the heat dissipation will not be good, and adjacent lines will also be easily disturbed. At the same time, the PCB shape The accuracy of dimensions and specifications directly affect the manufacturability and economy of production and processing. The main contents of PCB outline design include:

(1) Aspect ratio design. The shape of the printed board should be as simple as possible, generally rectangular, with an aspect ratio of 3:2 or 4:3, and should be as close to the standard size as possible. Do not design the board surface too large, otherwise it will easily cause deformation during reflow soldering. The thickness of the board should also match the size of the board. For a thinner PCB, the board size should not be too large.

(2) PCB shape. The shape and size of the PCB are determined by the transmission mode and transmission range of the placement machine. When the PCB is positioned on the mounting workbench and the PCB is transmitted through the...

What are the requirements of SMT production equipment for PCB

(Summary description)When designing a PCB, the first consideration is the shape of the PCB. When the size of the PCB is too large, the printed lines will increase, resulting in increased impedance and reduced noise immunity, and the cost will increase accordingly; if the size is too small, the heat dissipation will not be good, and adjacent lines will also be easily disturbed. At the same time, the PCB shape The accuracy of dimensions and specifications directly affect the manufacturability and economy of production and processing. The main contents of PCB outline design include:

(1) Aspect ratio design. The shape of the printed board should be as simple as possible, generally rectangular, with an aspect ratio of 3:2 or 4:3, and should be as close to the standard size as possible. Do not design the board surface too large, otherwise it will easily cause deformation during reflow soldering. The thickness of the board should also match the size of the board. For a thinner PCB, the board size should not be too large.

(2) PCB shape. The shape and size of the PCB are determined by the transmission mode and transmission range of the placement machine. When the PCB is positioned on the mounting workbench and the PCB is transmitted through the...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-07

- Views:0

When designing a PCB, the first consideration is the shape of the PCB. When the size of the PCB is too large, the printed lines will increase, resulting in increased impedance and reduced noise immunity, and the cost will increase accordingly; if the size is too small, the heat dissipation will not be good, and adjacent lines will also be easily disturbed. At the same time, the PCB shape The accuracy of dimensions and specifications directly affect the manufacturability and economy of production and processing. The main contents of PCB outline design include:

(1) Aspect ratio design. The shape of the printed board should be as simple as possible, generally rectangular, with an aspect ratio of 3:2 or 4:3, and should be as close to the standard size as possible. Do not design the board surface too large, otherwise it will easily cause deformation during reflow soldering. The thickness of the board should also match the size of the board. For a thinner PCB, the board size should not be too large.

(2) PCB shape. The shape and size of the PCB are determined by the transmission mode and transmission range of the placement machine. When the PCB is positioned on the mounting workbench and the PCB is transmitted through the workbench, there is no requirement on the PCB shape; when the PCB is directly transmitted by the guide rail, the shape of the PCB must be straight, if it is a special-shaped PCB, the process must be designed to make the PCB The shape is straight, and at the same time, it is best to process the PCB shape to a rounded corner or a 45° chamfer to prevent the PCB conveyor belt from being damaged by the acute angle when the board is loaded.

(3) PCB size design. The PCB size is determined by the mounting range. The maximum and minimum mounting sizes of the mounting machine should be considered when designing. Different types of mounting machines have different sizes. When the PCB size is smaller than the minimum mounting size, the boarding method must be adopted.

(4) PCB thickness design. Generally, the allowable board thickness of the placement machine is within 0.5~2mm. Only low-power components such as integrated circuits, low-power transistors, resistors and capacitors are assembled. Under the condition of no strong load and vibration, PCBs with a size within 500*500mm are used. The thickness is 1.6mm; under load vibration conditions, the size of the board can be reduced or the support points can be strengthened, and the thickness remains the same; if the board surface is too large to support, a 2~3mm thick board should be used.

The above is about the requirements of SMT production equipment for PCB design, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback