新闻资讯banner

What are the requirements of the SMT process for the placement machine

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-08

- Views:0

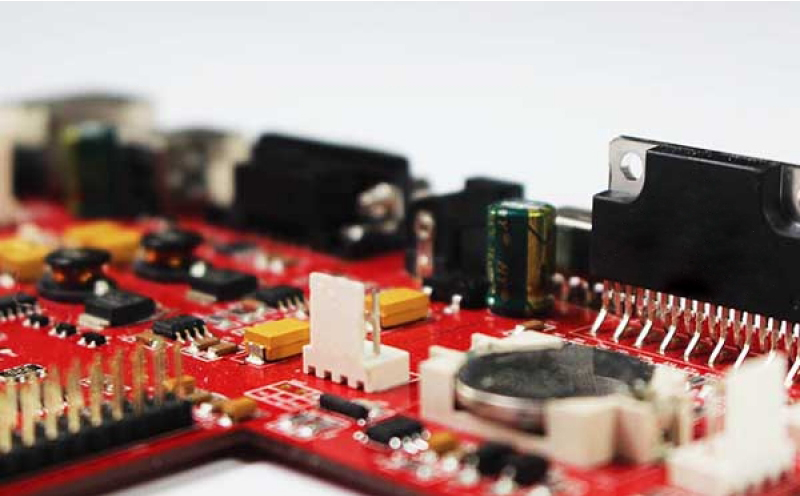

(Summary description)We know that the SMT placement machine is the electronic manufacturing equipment with the highest technical content and a large proportion of value in the SMT process. The SMT process has three main requirements for the placement machine: accurate placement, good placement, and fast placement. Below we will take a look at the specific items of these requirements.

(1) The stickers are accurate. There are two main elements for accurate placement: the correct components and the correct position of the components. ①The components are correct: the model, type, nominal value and other characteristic marks of the components in each assembly position must meet the product assembly and detail requirements, and the wrong position cannot be pasted. ②The position of the component is correct: the end or lead of the component and the position and angle of the target graphic should be aligned in the center as far as possible.

(2) It is posted well. There are three main criteria for good attachment: no damage...

What are the requirements of the SMT process for the placement machine

(Summary description)We know that the SMT placement machine is the electronic manufacturing equipment with the highest technical content and a large proportion of value in the SMT process. The SMT process has three main requirements for the placement machine: accurate placement, good placement, and fast placement. Below we will take a look at the specific items of these requirements.

(1) The stickers are accurate. There are two main elements for accurate placement: the correct components and the correct position of the components. ①The components are correct: the model, type, nominal value and other characteristic marks of the components in each assembly position must meet the product assembly and detail requirements, and the wrong position cannot be pasted. ②The position of the component is correct: the end or lead of the component and the position and angle of the target graphic should be aligned in the center as far as possible.

(2) It is posted well. There are three main criteria for good attachment: no damage...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-09-08

- Views:0

We know that the SMT placement machine is the electronic manufacturing equipment with the highest technical content and a large proportion of value in the SMT process. The SMT process has three main requirements for the placement machine: accurate placement, good placement, and fast placement. Below we will take a look at the specific items of these requirements.

(1) The stickers are accurate. There are two main elements for accurate placement: the correct components and the correct position of the components. ①The components are correct: the model, type, nominal value and other characteristic marks of the components in each assembly position must meet the product assembly and detail requirements, and the wrong position cannot be pasted. ②The position of the component is correct: the end or lead of the component and the position and angle of the target graphic should be aligned in the center as far as possible.

(2) It is posted well. There are three main criteria for good attachment: no damage to components, proper pressure, and guaranteed placement rate. ①No damage to components: When picking up or placing components on the SMT placement machine, the components may be damaged due to the errors of the feeder, components and printed boards, or the failure of the Z-axis control, resulting in poor placement.

②The pressure is appropriate: if the pressure of the patch is too small, the solder ends or pins of the components will float on the surface of the solder paste, and the solder paste will not stick to the components, and the components will easily move during transfer and reflow; the placement pressure is too high When the amount of solder paste is too much, it will cause solder paste adhesion, which is prone to bridging during reflow soldering, and may even damage components.

③ Guaranteed placement rate: due to unreasonable adjustment of placement machine parameters or poor component placement performance, as well as feeder and suction nozzle failures, components will be thrown during the placement process. In actual production, when the placement rate of the placement machine is lower than the preset level, it is necessary to check whether the placement machine fails, so as to adjust in time to ensure the placement rate.

(3) Post fast. In SMT processing and production, generally there are many components on the PCB circuit board, and each component must be attached one by one, so the mounting speed determines the mounting efficiency. However, the placement speed depends on the speed of the placement machine, but also the placement equipment, placement process, etc.

The above is about the requirements of the SMT process for the placement machine, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback