新闻资讯banner

What are the requirements of the wave soldering process for PCBA

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-07-24

- Views:0

(Summary description)In the PCBA processing technology, wave soldering is an extremely important link, and there are strict requirements for PCBA boards, which are mainly reflected in the requirements for PCB design, component placement, material solderability characteristics, and flux. What are the specific requirements for these aspects? Let's take a look at Sanjing below.

The first one is the requirements for PCB design. The layout and direction of the components should follow the principle of smaller components in the front and avoid mutual shielding as much as possible.

The second is the requirements for printed circuit boards. The PCB should have heat resistance that can withstand the high temperature of...

What are the requirements of the wave soldering process for PCBA

(Summary description)In the PCBA processing technology, wave soldering is an extremely important link, and there are strict requirements for PCBA boards, which are mainly reflected in the requirements for PCB design, component placement, material solderability characteristics, and flux. What are the specific requirements for these aspects? Let's take a look at Sanjing below.

The first one is the requirements for PCB design. The layout and direction of the components should follow the principle of smaller components in the front and avoid mutual shielding as much as possible.

The second is the requirements for printed circuit boards. The PCB should have heat resistance that can withstand the high temperature of...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-07-24

- Views:0

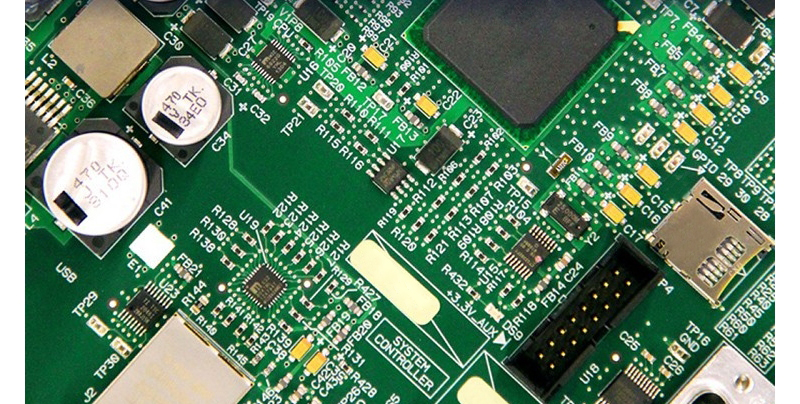

In the PCBA processing technology, wave soldering is an extremely important link, and there are strict requirements for PCBA boards, which are mainly reflected in the requirements for PCB design, component placement, material solderability characteristics, and flux. What are the specific requirements for these aspects? Let's take a look at Sanjing below.

The first one is the requirements for PCB design. The layout and direction of the components should follow the principle of smaller components in the front and avoid mutual shielding as much as possible.

The second is the requirements for printed circuit boards. The PCB should have heat resistance that can withstand the high temperature of 260℃ for more than 50s, the copper foil has good peeling strength, and the solder mask still has sufficient adhesion at high temperatures. The solder mask should not wrinkle or burn after soldering. The warpage of the printed circuit board is less than 0.8%~1.0%.

Third, the requirements for mounting components.

The metal electrode of surface mount and assembly components should choose a three-layer terminal structure. The component package body and SMT patch soldering end can withstand more than two temperature shocks of 260℃±5℃, 10s±0.5s wave soldering (no The lead requirement is 270~272℃/10s±0.5s). After soldering, the component package body is not damaged, cracked, discolored, deformed, brittle, and has no peeling (cap off) at the end; ensure that the electrical performance parameters of the components after wave soldering meet the requirements defined in the specification.

Fourth, the requirements for plug-in components. Using short-insertion one-time welding process, the component pins should be exposed, and the welding surface should be 0.8-3mm.

Fifth, the requirements for flux. For successful PCBA wave soldering, the flux coating must be uniform and the coating thickness must also be controlled. In order for the flux to work (on the wave crest, the flux can help reduce the surface tension of the solder, and prevent the solder from peeling and draining from the metal surface when the board exits the crest, causing solder bridges or icicles), the flux must penetrate into the hole and Apply to the pins.

Finally, the PCBA board must be preheated before wave soldering. This can not only help increase the surface temperature of the soldering, make the flux and the soldering surface quickly react to solder, but also slow down the temperate impact on the component (too large temperature gradient may cause the component performance to decline).

The above are the requirements of the wave soldering process for PCBA, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback