新闻资讯banner

What is SMT assembly

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-27

- Views:0

(Summary description)Before introducing SMT assembly, let's take a brief look at SMT. SMT is the abbreviation of surface mount technology, which is an assembly technology used to paste components (SMC surface mount components or SMD surface mount devices) through the application of a series of assembly equipment to expose PCBs (printed circuit boards).

Today, SMT components have been widely used in various fields, including medical, automotive, telecommunications, computers, industrial control, military, aerospace and other fields.

The equipment used in SMT assembly generally includes: solder paste printer, placement machine, reflow oven, AOI (automatic optical inspection) instrument, magnifying glass or microscope, etc.

SMT assembly procedures usually include solder paste printing, chip mounting, reflow soldering, AOI, X-ray inspection and...

What is SMT assembly

(Summary description)Before introducing SMT assembly, let's take a brief look at SMT. SMT is the abbreviation of surface mount technology, which is an assembly technology used to paste components (SMC surface mount components or SMD surface mount devices) through the application of a series of assembly equipment to expose PCBs (printed circuit boards).

Today, SMT components have been widely used in various fields, including medical, automotive, telecommunications, computers, industrial control, military, aerospace and other fields.

The equipment used in SMT assembly generally includes: solder paste printer, placement machine, reflow oven, AOI (automatic optical inspection) instrument, magnifying glass or microscope, etc.

SMT assembly procedures usually include solder paste printing, chip mounting, reflow soldering, AOI, X-ray inspection and...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-27

- Views:0

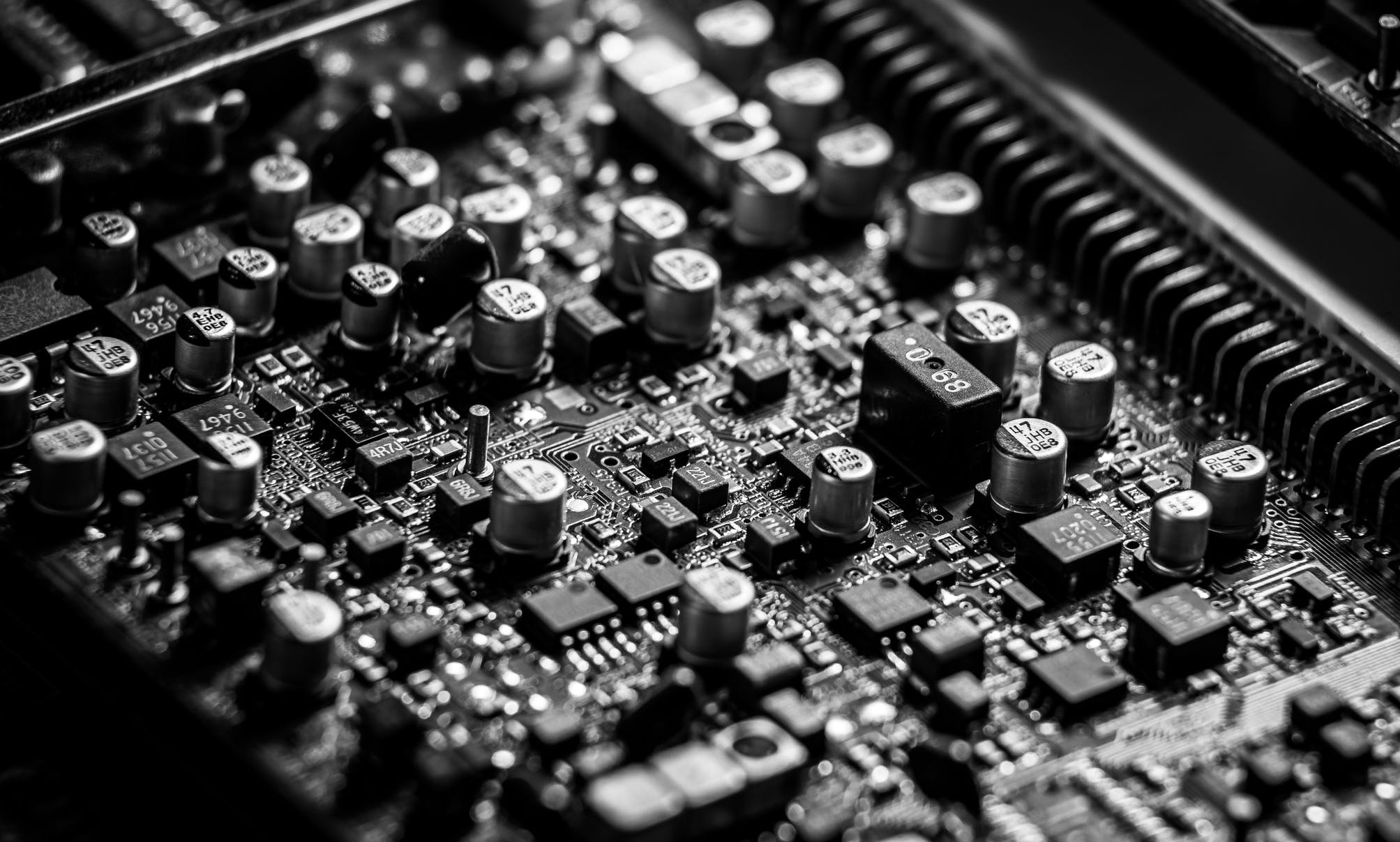

Before introducing SMT assembly, let's take a brief look at SMT. SMT is the abbreviation of surface mount technology, which is an assembly technology used to paste components (SMC surface mount components or SMD surface mount devices) through the application of a series of assembly equipment to expose PCBs (printed circuit boards).

Today, SMT components have been widely used in various fields, including medical, automotive, telecommunications, computers, industrial control, military, aerospace and other fields.

The equipment used in SMT assembly generally includes: solder paste printer, placement machine, reflow oven, AOI (automatic optical inspection) instrument, magnifying glass or microscope, etc.

SMT assembly procedures usually include solder paste printing, chip mounting, reflow soldering, AOI, X-ray inspection and rework, and visual inspections are performed after each procedure is completed.

The PCB assembled by SMT must be cleaned before leaving the workshop, because the surface of the assembled PCB is easily covered by dust, or there are residues after reflow soldering, such as flux, which will affect product quality to a certain extent and reduce product reliability.

Compared with traditional assembly technology (ie THT through-hole technology), SMT assembly can be automated, and SMT assembly assembly density is higher, smaller volume, lighter product weight, higher impact, lower defect rate, and higher frequency High, can reduce EMI (electromagnetic interference) and RF (radio frequency) interference, higher throughput, more automated visits, and lower cost.

Due to the heavy weight, high density, and large volume of THT components, THT assembly is suitable for wave soldering, and SMT assembly is suitable for reflow soldering. In addition, the leads of SMT components are shorter than those of THT components; THT components need to be drilled on the bare circuit board, while SMT does not need to be drilled because the SMC or SMD is directly mounted on the PCB.

At present, electronic products are developing towards miniaturization and light weight. It is difficult for THT assembly to meet the technical requirements. In order to concentrate the functions of electronic products, IC (integrated circuit) components have been fully utilized to a large extent to meet the needs of large-scale and high-integrity Due to sexual requirements, SMT components are widely used in the electronics manufacturing industry.

SMT assembly is suitable for automated mass production and can effectively reduce costs. The application of SMT assembly can better promote the development of various applications of electronic technology, integrated circuits and semiconductor materials, and comply with international electronic manufacturing standards.

The above is about the content of SMT assembly, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback