新闻资讯banner

What operating matters should be paid attention to in PCBA patch processing

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-10-14

- Views:0

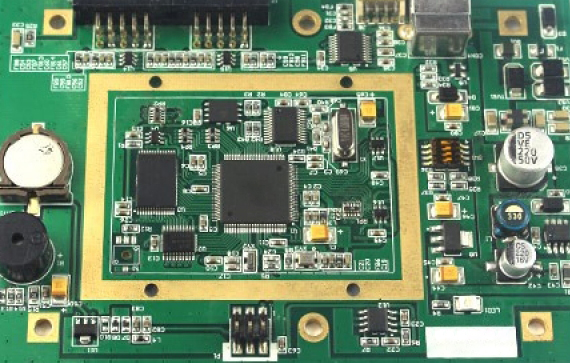

(Summary description)PCBA patch processing is the process of passing through SMT on the empty PCB board, and then through the DIP plug-in process. It involves many delicate and complicated process flows and some sensitive components. If the operation is not standardized, it will cause component damage or process defects, which will ultimately affect product quality and increase unnecessary processing costs. Therefore, in the PCBA patch processing, it is necessary to strictly follow some operating rules. The following Sanjing will be briefly introduced.

(1) Keep the workbench in the PCBA work area clean and tidy. No food or drink is allowed to be stored, personal items not related to work are strictly prohibited, and smoking is strictly prohibited.

(2) PCBA patch processing cannot take the surface to be soldered with bare hands, because the grease in the fingers will reduce the solderability of the circuit board, thereby increasing the probability of soldering defects.

(3) It is forbidden to stack the circuit boards together to avoid physical damage. Special brackets should be...

What operating matters should be paid attention to in PCBA patch processing

(Summary description)PCBA patch processing is the process of passing through SMT on the empty PCB board, and then through the DIP plug-in process. It involves many delicate and complicated process flows and some sensitive components. If the operation is not standardized, it will cause component damage or process defects, which will ultimately affect product quality and increase unnecessary processing costs. Therefore, in the PCBA patch processing, it is necessary to strictly follow some operating rules. The following Sanjing will be briefly introduced.

(1) Keep the workbench in the PCBA work area clean and tidy. No food or drink is allowed to be stored, personal items not related to work are strictly prohibited, and smoking is strictly prohibited.

(2) PCBA patch processing cannot take the surface to be soldered with bare hands, because the grease in the fingers will reduce the solderability of the circuit board, thereby increasing the probability of soldering defects.

(3) It is forbidden to stack the circuit boards together to avoid physical damage. Special brackets should be...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-10-14

- Views:0

PCBA patch processing is the process of passing through SMT on the empty PCB board, and then through the DIP plug-in process. It involves many delicate and complicated process flows and some sensitive components. If the operation is not standardized, it will cause component damage or process defects, which will ultimately affect product quality and increase unnecessary processing costs. Therefore, in the PCBA patch processing, it is necessary to strictly follow some operating rules. The following Sanjing will be briefly introduced.

(1) Keep the workbench in the PCBA work area clean and tidy. No food or drink is allowed to be stored, personal items not related to work are strictly prohibited, and smoking is strictly prohibited.

(2) PCBA patch processing cannot take the surface to be soldered with bare hands, because the grease in the fingers will reduce the solderability of the circuit board, thereby increasing the probability of soldering defects.

(3) It is forbidden to stack the circuit boards together to avoid physical damage. Special brackets should be configured at the work site, and the PCBA circuit boards should be placed completely according to the type.

(4) The operation steps of PCBA processing and components should be as simple as possible to prevent errors caused by complicated steps. Gloves must be worn for assembly. Since dirty gloves will cause pollution, they must be replaced frequently when necessary.

(5) Do not use skin-protecting oils to coat hands or various silicone-containing detergents, as they will cause problems in solderability. You can use professional cleaning agents for cleaning the PCBA soldering surface.

(6) Electrostatic sensitive components must use anti-static labels to avoid confusion with other components. In addition, in order to prevent static electricity from endangering sensitive components, all operations, assembly and testing must be completed on an anti-static workbench.

(7) Regularly check the anti-static workbench to confirm that it can work normally (anti-static). Electronic components may sometimes fail due to incorrect grounding methods or the presence of oxides in the grounding part. Therefore, the joints of the grounding terminal must be specially protected.

In PCBA patch processing, the above rules should be strictly followed, and the correct operation can ensure the quality of the final product, reduce component damage and reduce costs.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback