新闻资讯banner

What processing rules need to be followed during PCBA processing

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-09-01

- Views:0

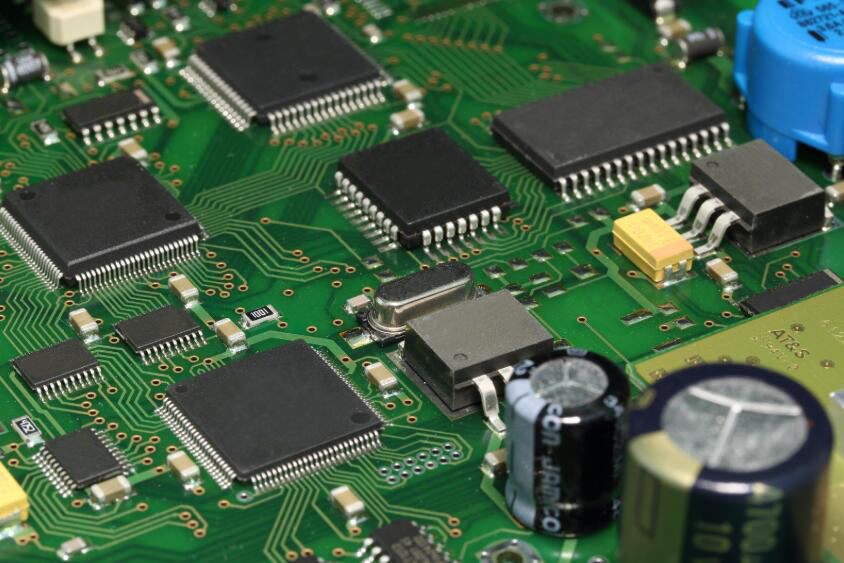

(Summary description)As we all know, for precision machining, incorrect operations can cause damage to components and PCBA, causing cracks, breaks, open circuits, and bending fractures of components and connectors. Therefore, if you want to avoid these situations, you must strictly follow the PCBA processing rules. The following Sanjing let everyone know which rules to comply with in the PCBA processing link and operation process:

The first is to keep the working environment clean. The working environment consists of two parts: one is the workshop area and the other is the workbench. No matter which area should be kept clean and tidy, in addition to prohibiting the placing of flammable and explosive materials in the work area, smoking and other behaviors that may cause fire accidents should be prohibited.

Reduce PCBA processing steps. We know that there are many PCBA processing steps, but...

What processing rules need to be followed during PCBA processing

(Summary description)As we all know, for precision machining, incorrect operations can cause damage to components and PCBA, causing cracks, breaks, open circuits, and bending fractures of components and connectors. Therefore, if you want to avoid these situations, you must strictly follow the PCBA processing rules. The following Sanjing let everyone know which rules to comply with in the PCBA processing link and operation process:

The first is to keep the working environment clean. The working environment consists of two parts: one is the workshop area and the other is the workbench. No matter which area should be kept clean and tidy, in addition to prohibiting the placing of flammable and explosive materials in the work area, smoking and other behaviors that may cause fire accidents should be prohibited.

Reduce PCBA processing steps. We know that there are many PCBA processing steps, but...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-09-01

- Views:0

As we all know, for precision machining, incorrect operations can cause damage to components and PCBA, causing cracks, breaks, open circuits, and bending fractures of components and connectors. Therefore, if you want to avoid these situations, you must strictly follow the PCBA processing rules. The following Sanjing let everyone know which rules to comply with in the PCBA processing link and operation process:

The first is to keep the working environment clean. The working environment consists of two parts: one is the workshop area and the other is the workbench. No matter which area should be kept clean and tidy, in addition to prohibiting the placing of flammable and explosive materials in the work area, smoking and other behaviors that may cause fire accidents should be prohibited.

Reduce PCBA processing steps. We know that there are many PCBA processing steps, but sometimes PCBA processing steps are not as many as possible. Conversely, the more steps, the more likely to go wrong. Therefore, appropriately reducing some of the steps that are not particularly critical can also reduce the probability of problems to a certain extent.

Do not operate with bare hands. The oil secreted in the hands of the human body will reduce the solderability of the components, so it cannot be directly operated with bare hands. By the way, I would like to remind you that no matter which step you perform, you must wear gloves, one is to avoid hurting your hands and causing work injuries, and the other is to avoid the impact of human electrostatic voltage on the product. In order to be able to operate better, gloves should also be replaced frequently.

Do not use hand creams and detergents containing silicone resins. Both of these things can lead to reduced solderability, which can lead to coating failures.

Do not stack PCBA. PCBA has a dedicated bracket specially configured. Sometimes in the actual operation process, some novice employees will stack the PCBA boards because they are not proficient in the operation, which can easily cause physical damage to the PCBA boards.

Choose suitable marks for sensitive components. Among PCBA components, there are some more sensitive components, such as EOS/ESD, etc., which are all very sensitive components, so you must choose the appropriate logo. In addition, static electricity needs to be controlled during operation.

The above points are about the processing rules that need to be followed in the PCBA processing process, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback