新闻资讯banner

Why control the temperature and humidity of the SMT workshop

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-10-09

- Views:0

(Summary description)In the production process, different production processes have different requirements for the environment, which requires the temperature and humidity of the production environment to be controlled.

Clean room generally refers to the removal of particulates, harmful air, bacteria and other pollutants in the air within a certain space, and the control of indoor temperature, cleanliness, indoor pressure, air velocity and air distribution, noise, vibration, lighting, and static electricity. Specially designed workshops within a certain range of requirements.

The temperature and humidity standards of dust-free purification workshops in different industries are different. Let’s take a look at the following Sanjing:

(1) The temperature and humidity standard of the clean workshop of the electronics manufacturing industry is generally around 22℃, and the relative humidity is controlled between 50% and 60%. There are relevant temperature and humidity regulations for the special clean workshop...

Why control the temperature and humidity of the SMT workshop

(Summary description)In the production process, different production processes have different requirements for the environment, which requires the temperature and humidity of the production environment to be controlled.

Clean room generally refers to the removal of particulates, harmful air, bacteria and other pollutants in the air within a certain space, and the control of indoor temperature, cleanliness, indoor pressure, air velocity and air distribution, noise, vibration, lighting, and static electricity. Specially designed workshops within a certain range of requirements.

The temperature and humidity standards of dust-free purification workshops in different industries are different. Let’s take a look at the following Sanjing:

(1) The temperature and humidity standard of the clean workshop of the electronics manufacturing industry is generally around 22℃, and the relative humidity is controlled between 50% and 60%. There are relevant temperature and humidity regulations for the special clean workshop...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-10-09

- Views:0

In the production process, different production processes have different requirements for the environment, which requires the temperature and humidity of the production environment to be controlled.

Clean room generally refers to the removal of particulates, harmful air, bacteria and other pollutants in the air within a certain space, and the control of indoor temperature, cleanliness, indoor pressure, air velocity and air distribution, noise, vibration, lighting, and static electricity. Specially designed workshops within a certain range of requirements.

The temperature and humidity standards of dust-free purification workshops in different industries are different. Let’s take a look at the following Sanjing:

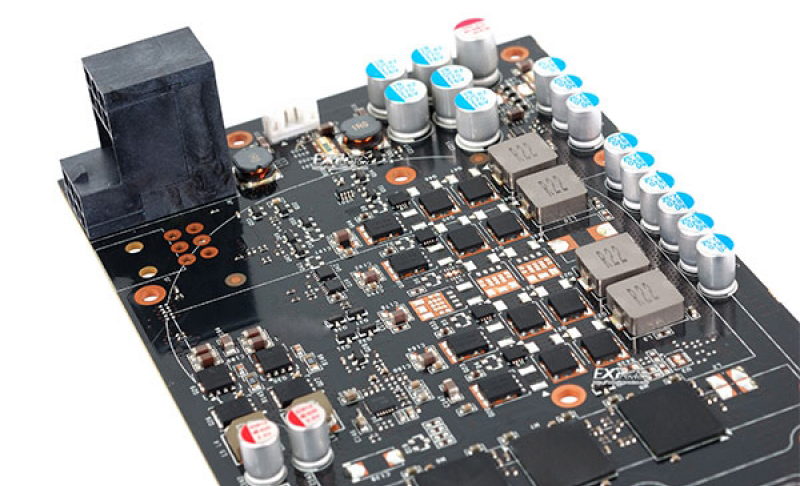

(1) The temperature and humidity standard of the clean workshop of the electronics manufacturing industry is generally around 22℃, and the relative humidity is controlled between 50% and 60%. There are relevant temperature and humidity regulations for the special clean workshop. Chip production workshops, integrated circuit clean rooms and disk manufacturing workshops are also important components of clean rooms in the electronics manufacturing industry. Because electronic products have extremely strict requirements on indoor air environment and quality during the manufacturing and production process, the main control is to control particles and floating dust. At the same time, strict regulations are made on the temperature and humidity of the environment, the amount of fresh air, and noise.

(2) The temperature and humidity standard of SMT clean room: temperature 23±3℃, humidity 30%~70%. SMT surface mount mainly includes three main production processes: solder paste printing, component mounting, and reflow soldering. Product quality is the core content of all manufacturing companies, and the quality of solder paste printing has the greatest impact on the quality of surface mounting.

Temperature and humidity will affect the quality of solder paste printing. As the temperature rises, the viscosity of the solder paste will become lower, and then it will easily cause the backlog to spread. During printing, the solder paste spreads to the side and bridges. At the same time, the lower the viscosity will cause the printed tin block to be insufficiently retained, thereby forming a collapsed bridge. In addition, the lower viscosity of the solder paste will also cause defects, poor demolding, plugging, and poor molding. The humidity determines how much moisture the solder paste absorbs in the air. If too much moisture is inhaled, it will cause pores, splashes, continuous soldering, etc. during reflow. Therefore, in order to improve the quality of solder paste printing and make the solder paste work in a better environment, it is necessary to balance the workshop temperature and humidity within the standard range to ensure the normal process of the process and ensure the final quality of the solder paste.

The above is about why we need to control the temperature and humidity of the clean workshop, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback