新闻资讯banner

Why does PCBA conduct the first inspection

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-08-21

- Views:0

(Summary description)Before introducing the PCBA first inspection, I believe many people don't know what the PCBA first inspection is. The following Sanjing will give you a brief introduction. The first PCBA inspection is to inspect the first or the first few products produced during the production process, after each shift/production line starts production. Certain samples taken are also called the first inspection. The quantity of the first inspection will also vary according to the requirements of the enterprise or customer, but in general, the PCBA first inspection requires the product to be inspected, and mass production can be carried out after ensuring that it is qualified. This is generally a regular PCBA production An essential link for manufacturers.

However, many electronic companies often do not require the first inspection when working...

Why does PCBA conduct the first inspection

(Summary description)Before introducing the PCBA first inspection, I believe many people don't know what the PCBA first inspection is. The following Sanjing will give you a brief introduction. The first PCBA inspection is to inspect the first or the first few products produced during the production process, after each shift/production line starts production. Certain samples taken are also called the first inspection. The quantity of the first inspection will also vary according to the requirements of the enterprise or customer, but in general, the PCBA first inspection requires the product to be inspected, and mass production can be carried out after ensuring that it is qualified. This is generally a regular PCBA production An essential link for manufacturers.

However, many electronic companies often do not require the first inspection when working...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-08-21

- Views:0

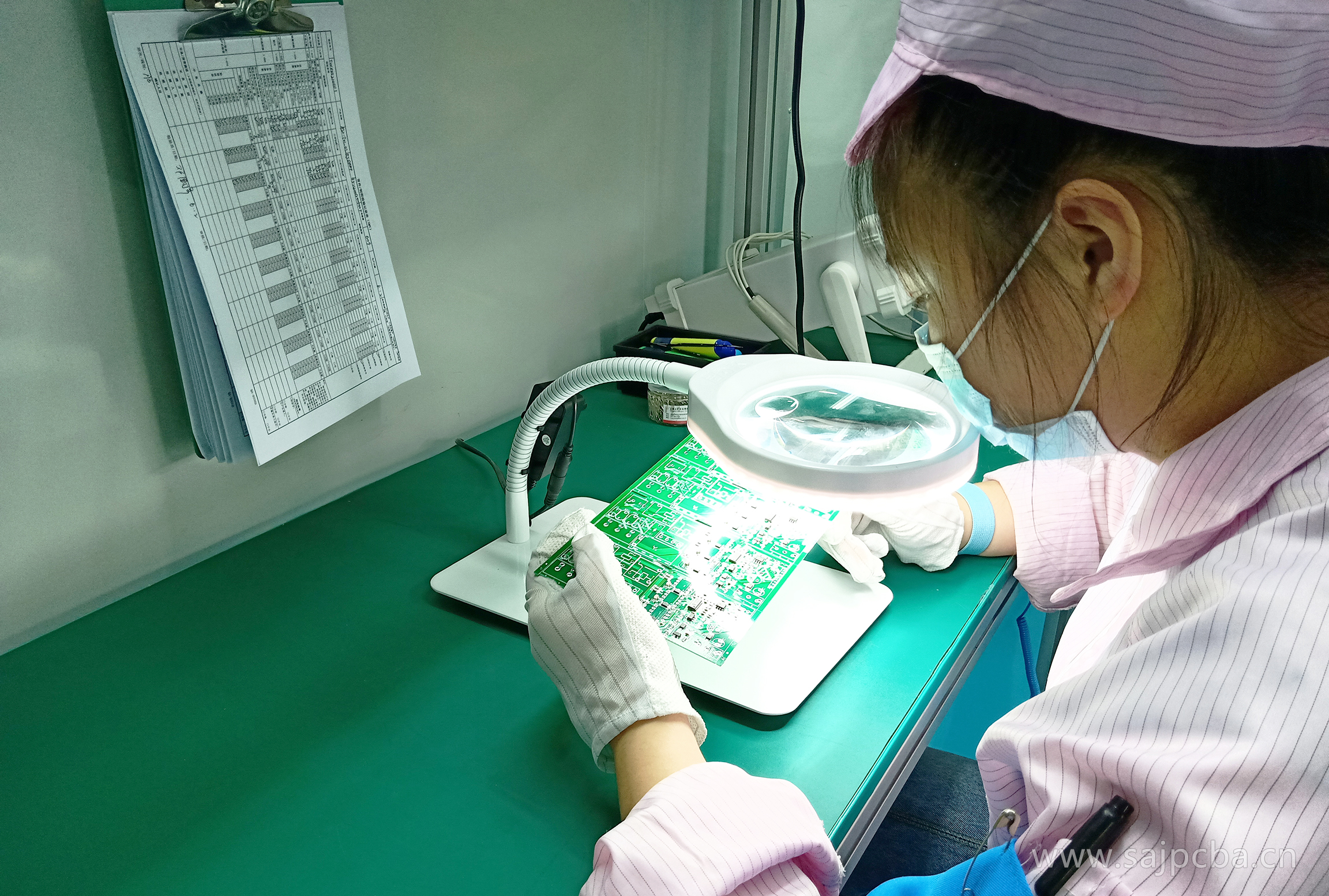

Before introducing the PCBA first inspection, I believe many people don't know what the PCBA first inspection is. The following Sanjing will give you a brief introduction. The first PCBA inspection is to inspect the first or the first few products produced during the production process, after each shift/production line starts production. Certain samples taken are also called the first inspection. The quantity of the first inspection will also vary according to the requirements of the enterprise or customer, but in general, the PCBA first inspection requires the product to be inspected, and mass production can be carried out after ensuring that it is qualified. This is generally a regular PCBA production An essential link for manufacturers.

However, many electronic companies often do not require the first inspection when working with PCBA manufacturers, and do not pay much attention to the first inspection because they do not know the importance of the first inspection. Then Sanjing will take you to understand why the first inspection is required.

In order to prevent the occurrence of large quantities of unqualified products, repair or scrapping of products in the production process, PCBA manufacturers will conduct the first inspection in advance, which shows the importance of the first inspection:

First of all, the first one is to avoid waste of resources. Why do you say that? Because of the PCBA first inspection, it can avoid a large number of products that are not of good quality, repaired or even scrapped, so that resources can be fully utilized, and a large amount of resources will not be wasted. For enterprises, it can also save a certain amount of cost and reduce cost input.

The second is quality assurance. PCBA first inspection is an important means to control the quality of PCBA production. It can control the quality of PCBA and help PCBA manufacturers determine the production quality of the batch of products, thereby improving the economic efficiency of the enterprise.

The third is to improve production efficiency and reputation. Sometimes even if the product quality is good, if there is too much waste in the production process, resulting in a low yield, that is, low production efficiency, it will also cause customers to question. Because of this, many PCBA manufacturers, in order to enhance their corporate image and reputation, strictly follow the PCBA production process to control product quality, such as product qualification rate, yield rate and quality rate. When these data exceed the general production standards, it will have a better reputation among the peers, thereby attracting more customers. In addition, the importance of the first PCBA inspection is also reflected in the cost, which can not only improve production efficiency, but also save a certain amount of cost.

All in all, the first PCBA inspection is very important, and we cannot ignore it.

The above content is about the reasons for the first inspection of PCBA, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback