新闻资讯banner

Why does the PCBA board cock up?

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-07-29

- Views:0

(Summary description)We know that PCBA boards are easily deformed due to various factors during reflow soldering or wave soldering, resulting in poor PCBA soldering. Poor soldering has become a common problem in PCBA production. Once a poor soldering phenomenon occurs, it will cause our products to malfunction and sometimes even fail to operate normally. This is a headache for production personnel. Today, Sanjing will take you to understand the causes of PCBA board deformation (uplifting).

1. The furnace temperature, each circuit board has a maximum TG value. When the reflow soldering temperature is higher than the maximum TG value of the circuit board, it will cause the board to soften and deform.

Second, it is the PCB board problem. With the popularity of lead-free technology, the furnace temperature is higher than the lead temperature, so the requirements for the sheet are getting higher and higher. The lower the TG value of the board, the easier it is to deform when passing...

Why does the PCBA board cock up?

(Summary description)We know that PCBA boards are easily deformed due to various factors during reflow soldering or wave soldering, resulting in poor PCBA soldering. Poor soldering has become a common problem in PCBA production. Once a poor soldering phenomenon occurs, it will cause our products to malfunction and sometimes even fail to operate normally. This is a headache for production personnel. Today, Sanjing will take you to understand the causes of PCBA board deformation (uplifting).

1. The furnace temperature, each circuit board has a maximum TG value. When the reflow soldering temperature is higher than the maximum TG value of the circuit board, it will cause the board to soften and deform.

Second, it is the PCB board problem. With the popularity of lead-free technology, the furnace temperature is higher than the lead temperature, so the requirements for the sheet are getting higher and higher. The lower the TG value of the board, the easier it is to deform when passing...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-07-29

- Views:0

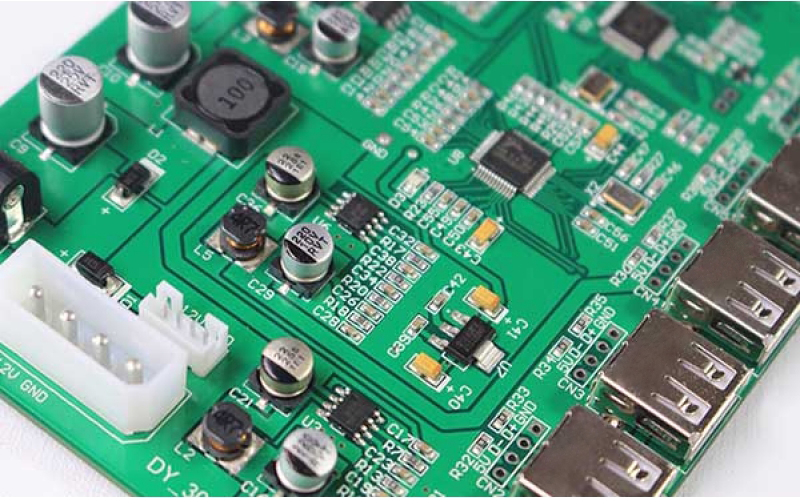

We know that PCBA boards are easily deformed due to various factors during reflow soldering or wave soldering, resulting in poor PCBA soldering. Poor soldering has become a common problem in PCBA production. Once a poor soldering phenomenon occurs, it will cause our products to malfunction and sometimes even fail to operate normally. This is a headache for production personnel. Today, Sanjing will take you to understand the causes of PCBA board deformation (uplifting).

1. The furnace temperature, each circuit board has a maximum TG value. When the reflow soldering temperature is higher than the maximum TG value of the circuit board, it will cause the board to soften and deform.

Second, it is the PCB board problem. With the popularity of lead-free technology, the furnace temperature is higher than the lead temperature, so the requirements for the sheet are getting higher and higher. The lower the TG value of the board, the easier it is to deform when passing the furnace, but the higher the TG value, the more expensive the board.

3. PCBA board thickness. With the development of electronic products in the direction of smaller, lighter, and thinner, the thickness of the circuit board is also required to be thinner and thinner. The thinner the thickness of the circuit board, the more easily deformed when passing through the reflow oven under the influence of high temperature.

4. PCBA board size and number of panels. When the circuit board is reflow soldered, it is generally placed on a chain for transmission. The chains on both sides are used as support points. If the circuit board is too large or the number of panels is too large, the circuit board will tend to dent in the middle and cause deformation.

5. The depth of V-Cut. V-Cut is to cut grooves on a large sheet of board. If the V-Cut line is too deep, it will also cause deformation of the PCBA board.

Sixth, the copper area on the PCBA board is uneven. Generally, a large area of copper foil is provided on a circuit board to serve as a grounding function. When these large area copper foils cannot be evenly distributed on the same circuit board, it will cause uneven heat absorption and heat dissipation speed of the circuit board. At the same time, the circuit board will also expand and contract with heat. If the expansion and contraction are different, different stresses will cause deformation. If the temperature of the board has reached the upper limit of the TG value at this time, the board will soften and cause permanent deformation.

Seven, the connection points of each layer on the PCBA board. Nowadays, most circuit boards are multi-layer boards with many drilled connection points. These connection points are through holes, blind holes, and buried holes; these connection points will limit the effect of thermal expansion and contraction of the circuit board, resulting in the board Deformed.

The above are the main reasons for the deformation of our PCBA board, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback