新闻资讯banner

Why does the SMT placement machine have a high throwing rate?

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-08-09

- Views:0

(Summary description)In SMT production, in addition to the production quality, the manufacturer also considers the corresponding production cost. At the same time, we know that although the production efficiency of the SMT automatic placement machine is relatively high, the throwing rate is actually relatively high. When it comes to throwing rate, I believe that many people still don't know what throwing rate means. The following is a brief introduction from Sanjing.

SMT throwing means that during the production process of the placement machine, there is no placement action after the material is sucked, but the material is thrown in the throwing box or other places, and the throwing action is performed without the material being sucked. It can be...

Why does the SMT placement machine have a high throwing rate?

(Summary description)In SMT production, in addition to the production quality, the manufacturer also considers the corresponding production cost. At the same time, we know that although the production efficiency of the SMT automatic placement machine is relatively high, the throwing rate is actually relatively high. When it comes to throwing rate, I believe that many people still don't know what throwing rate means. The following is a brief introduction from Sanjing.

SMT throwing means that during the production process of the placement machine, there is no placement action after the material is sucked, but the material is thrown in the throwing box or other places, and the throwing action is performed without the material being sucked. It can be...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-08-09

- Views:0

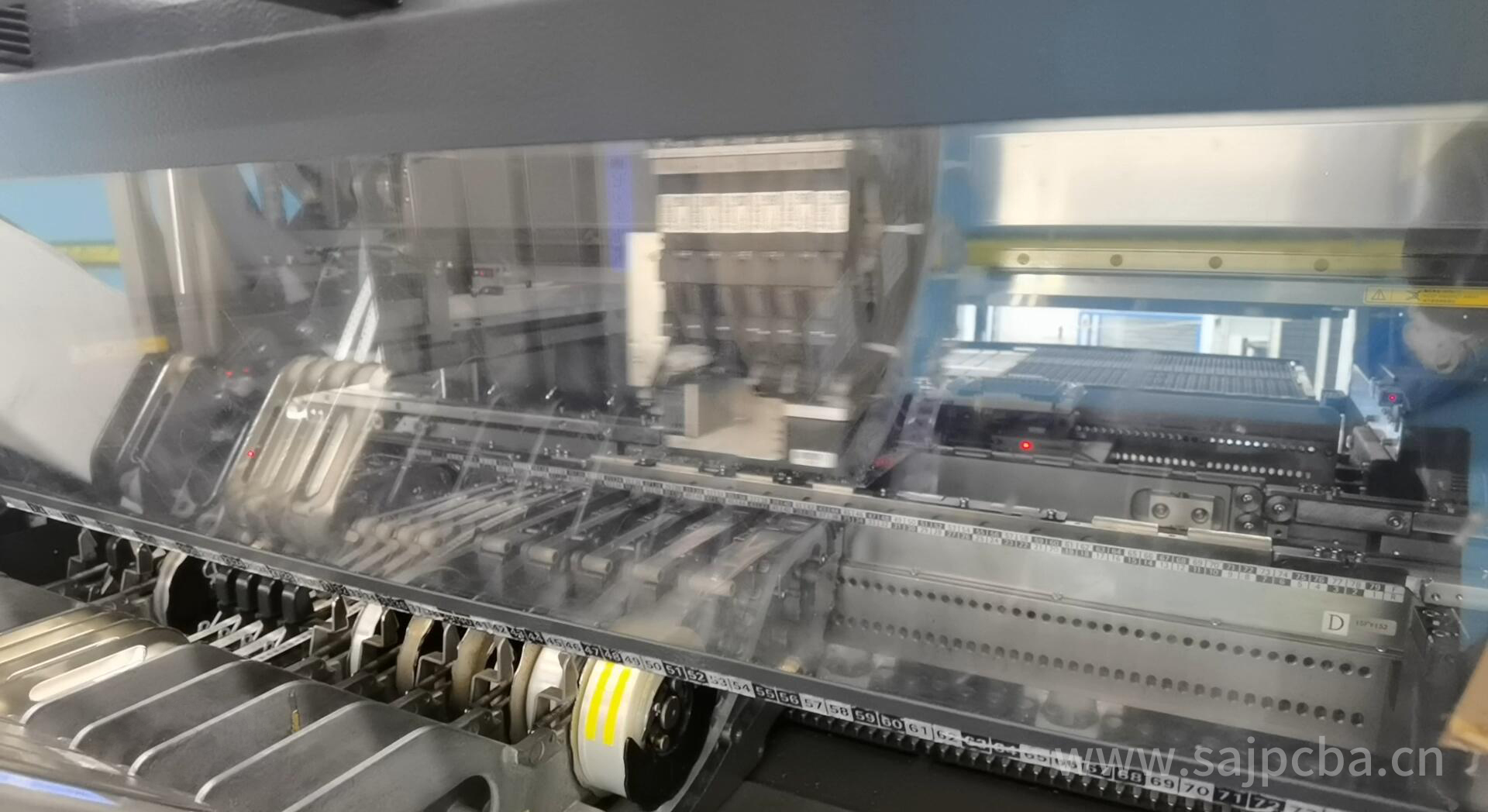

In SMT production, in addition to the production quality, the manufacturer also considers the corresponding production cost. At the same time, we know that although the production efficiency of the SMT automatic placement machine is relatively high, the throwing rate is actually relatively high. When it comes to throwing rate, I believe that many people still don't know what throwing rate means. The following is a brief introduction from Sanjing.

SMT throwing means that during the production process of the placement machine, there is no placement action after the material is sucked, but the material is thrown in the throwing box or other places, and the throwing action is performed without the material being sucked. It can be seen that the material loss caused by throwing is very large, and the production time will be prolonged at the same time, resulting in a decrease in production efficiency. And production efficiency is the top priority for SMT manufacturers.

However, there must be a reason for everything. The following Sanjing will take you to understand the reasons for the high throwing rate of the placement machine.

First of all, the first one may be a problem with the SMT identification system. When there is dirt or debris on the vision or laser lens, it will interfere with the system recognition. If the recognition light source is selected incorrectly, the intensity grayscale is not enough, and the recognition system malfunctions, it will cause material throwing.

The second may be the problem of the patch nozzle. Deformation, blockage or damage of the suction nozzle will cause insufficient air pressure, which will lead to difficulty in suction or improper retrieval of materials, resulting in failure to identify and cause throwing.

The third possibility is that the reclaiming location is not appropriate. If the reclaiming material is not in the center of the material, it will easily lead to incorrect reclaiming, or improper reclaiming height causing deviation, etc., and the system will recognize it as invalid material, which will cause throwing and waste.

The fourth possibility is the vacuum problem of the SMT placement machine. When vacuum leakage causes insufficient air pressure or foreign matter in the vacuum air pipe is not smooth, it will cause difficulty in retrieving or falling during reclaim, resulting in waste of throwing materials.

Therefore, in view of the above issues, we need to analyze specific issues in detail. In view of the problem of the recognition system, we must frequently clean and wipe the surface of the recognition system to keep it clean. The intensity or gray scale is not enough and needs to be re-adjusted. If the identification system is damaged, it needs to be replaced with new identification system components. For the suction nozzle problem, what we can do is to replace the suction nozzle in time; for the picking position problem, we need to adjust the position during production; for the vacuum problem, we need to adjust the air pressure to the pressure value required by the equipment, and the vacuum tube has Clean up in time when the foreign body is blocked.

The above is about the reasons for the throwing of the SMT placement machine, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback