新闻资讯banner

Problems that need to be paid attention to when making ICT fixtures by PCBA

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-11-19

- Views:0

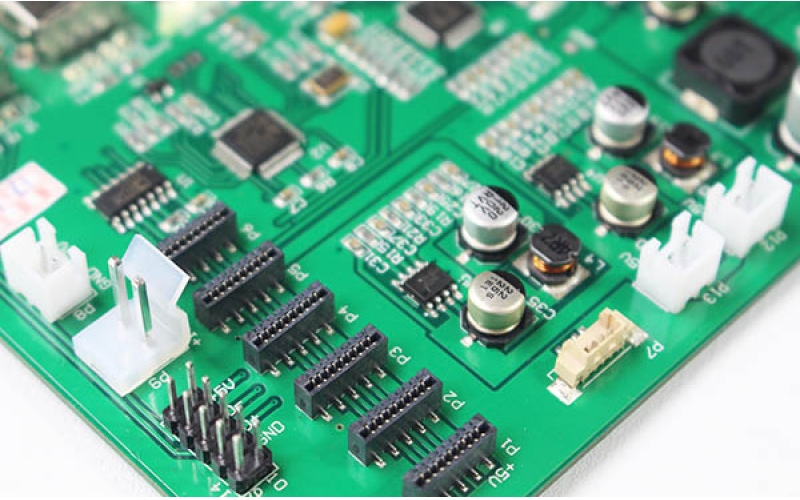

(Summary description)We know that PCBA fixture is indispensable in PCBA production and manufacturing. It is an important testing tool used to test PCBA products for defects. However, if you want the feedback of PCBA products to be more accurate during the testing process, you must be very rigorous and careful when making PCBA fixtures. Today, Sanjing will mainly take you to understand the issues that need to be paid attention to when making ICT fixtures:

(1) Selection of test points: Try to avoid double needles under the fixture, and it is best to place the test points on the same side. The priority order of selected points to be tested is: test point-DIP component pin-VIA via-SMT patch pin.

(2) Test point: ①The center distance between the two tested points or the tested point and the pre-drilled hole shall not be less...

Problems that need to be paid attention to when making ICT fixtures by PCBA

(Summary description)We know that PCBA fixture is indispensable in PCBA production and manufacturing. It is an important testing tool used to test PCBA products for defects. However, if you want the feedback of PCBA products to be more accurate during the testing process, you must be very rigorous and careful when making PCBA fixtures. Today, Sanjing will mainly take you to understand the issues that need to be paid attention to when making ICT fixtures:

(1) Selection of test points: Try to avoid double needles under the fixture, and it is best to place the test points on the same side. The priority order of selected points to be tested is: test point-DIP component pin-VIA via-SMT patch pin.

(2) Test point: ①The center distance between the two tested points or the tested point and the pre-drilled hole shall not be less...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-11-19

- Views:0

We know that PCBA fixture is indispensable in PCBA production and manufacturing. It is an important testing tool used to test PCBA products for defects. However, if you want the feedback of PCBA products to be more accurate during the testing process, you must be very rigorous and careful when making PCBA fixtures. Today, Sanjing will mainly take you to understand the issues that need to be paid attention to when making ICT fixtures:

(1) Selection of test points: Try to avoid double needles under the fixture, and it is best to place the test points on the same side. The priority order of selected points to be tested is: test point-DIP component pin-VIA via-SMT patch pin.

(2) Test point: ①The center distance between the two tested points or the tested point and the pre-drilled hole shall not be less than 0.050" (1.27mm), preferably greater than 0.100" (2.54mm), followed by 0.075" (1.905mm) .

②The test point distribution of the fixture should be as even as possible, and try to avoid placing the test point on the SMT part, because the contact surface is too small and it is easy to crush the part. At the same time, it is guaranteed that the board will not change shape after being pressed to avoid damage to the product.

③The measured points should be evenly distributed on the PCB surface to avoid excessive local density. They should be at least 0.100" away from the nearby parts (located on the same plane). If the parts are higher than 3m/m, the distance should be at least 0.120". In addition, the diameter of the measured point should not be too small (<0.035" or 0.9mm).

④Pad and Via of the tested point should not have solder resist, and should be at least 0.100" away from the edge of the board or folded edge. Try to avoid using too long part feet (>0.170" or 4.3mm) or too large aperture (>1.5mm) ).

(3) Positioning holes: ①The PCB to be tested must have two or more positioning holes, and the holes should not be tinted, and their location is best on the opposite corner of the PCB. ②The position tolerance between the measured point and the positioning hole should be ±0.002″. ③The positioning hole should be diagonal and the two most distant holes are the positioning holes. ④The diameter of the positioning hole is preferably 0.125″ (3.175mm), and the tolerance is within ﹢0.002″/﹣0.001″.

The above is about the issues that need to be paid attention to when making ICT fixtures with PCBA. I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback