新闻资讯banner

Reasons and countermeasures of PCBA processing throwing materials

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-12-23

- Views:0

(Summary description)As we all know, PCBA processing is an indispensable step in the SMT production process, and the quality of PCBA determines the quality of electronic products. Therefore, a good electronic product is inseparable from high-quality PCBA.

However, in PCBA processing, some production problems are often encountered, such as PCBA processing throwing. The following Sanjing introduces the reasons for PCBA processing throwing materials:

The first one may be the nozzle problem. The suction nozzle is deformed, blocked or damaged, resulting in insufficient air pressure and air leakage, resulting in the suction nozzle being unable to pick up material or picking up incorrectly, and the system cannot...

Reasons and countermeasures of PCBA processing throwing materials

(Summary description)As we all know, PCBA processing is an indispensable step in the SMT production process, and the quality of PCBA determines the quality of electronic products. Therefore, a good electronic product is inseparable from high-quality PCBA.

However, in PCBA processing, some production problems are often encountered, such as PCBA processing throwing. The following Sanjing introduces the reasons for PCBA processing throwing materials:

The first one may be the nozzle problem. The suction nozzle is deformed, blocked or damaged, resulting in insufficient air pressure and air leakage, resulting in the suction nozzle being unable to pick up material or picking up incorrectly, and the system cannot...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-12-23

- Views:0

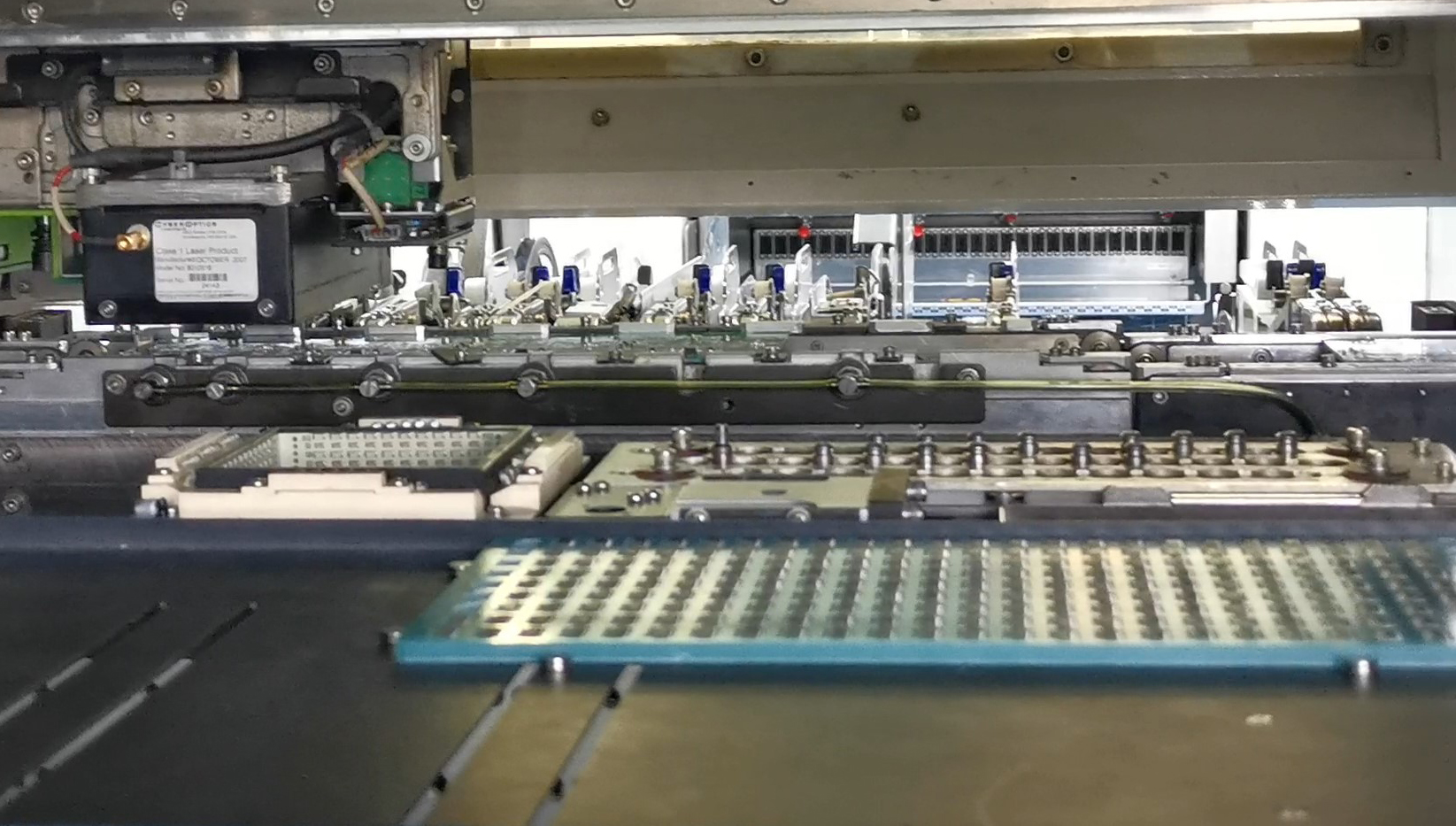

As we all know, PCBA processing is an indispensable step in the SMT production process, and the quality of PCBA determines the quality of electronic products. Therefore, a good electronic product is inseparable from high-quality PCBA.

However, in PCBA processing, some production problems are often encountered, such as PCBA processing throwing. The following Sanjing introduces the reasons for PCBA processing throwing materials:

The first one may be the nozzle problem. The suction nozzle is deformed, blocked or damaged, resulting in insufficient air pressure and air leakage, resulting in the suction nozzle being unable to pick up material or picking up incorrectly, and the system cannot recognize and lead to material throwing. The best solution at this time is to clean or replace the nozzle.

The second is the feeder problem. Improper setting of the feeder leads to a poor feeding mechanism, which results in failure to reclaim or poor reclaim. At this time, the feeder should be reset or replaced, and the equipment should be cleaned.

Third, identify system problems. The visual or laser lens has foreign objects that interfere with the recognition, the recognition light source is not selected properly or the intensity or gray scale is not enough, and it may be that the recognition system is damaged. In response to these situations, the surface of the identification system can be cleaned and wiped to keep it clean and free of foreign matter or oil interference. At the same time, the intensity and gray level of the light source can be adjusted, and the identification system components can be replaced.

Fourth, the reclaiming position is shifted. The suction nozzle is not in the center of the material when sucking the material, and at the same time, the incorrect height of the material leads to the deviation, and the recognition system does not match the corresponding data parameters and is discarded as invalid material by the recognition system. The best solution at this time is to adjust parameters such as the reclaiming position and height.

The last one is the vacuum problem. The vacuum pipe channel is not smooth, the vacuum pipe is blocked by foreign matter or the vacuum leaks, resulting in insufficient air pressure and unable to pick up the material, or fall off during the removal of the patch after being picked up. At this time, the best solution is to adjust the air pressure steep slope to the required air pressure value of the equipment, clean and dredge the pipeline, and repair the leaking air path.

In addition, static electricity is also one of the causes of PCBA throwing. Therefore, the placement machine must be grounded, and the production site must be protected against static electricity.

Generally speaking, it is normal for the placement machine to have PCBA throwing away, but if the PCBA throwing rate is relatively high, and it seriously affects the production efficiency and production cost, it must be solved as soon as possible. When there is serious material throwing in the production process, you can analyze the above possibilities to find the key to the problem, which can save time and find the problem faster and ensure production efficiency.

The above is about the content of PCBA processing and throwing materials, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback