新闻资讯banner

Selection and evaluation of lead-free solder paste

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-06-17

- Views:0

(Summary description)With the widespread development and popularization of lead-free, lead-free solder has been fully put into use. Lead-free solder paste has replaced the position of lead solder paste in the electronics manufacturing industry, but this has also brought new problems to solder paste printing. . In the transition from lead to lead-free, the two biggest material problems involved are the selection of solder paste and components. Choosing the right solder paste determines the quality of electronic products to a certain extent, so it must be targeted before choosing.Like lead-free solder paste, there are many manufacturers and specifications. Even the solder paste from the...

Selection and evaluation of lead-free solder paste

(Summary description)With the widespread development and popularization of lead-free, lead-free solder has been fully put into use. Lead-free solder paste has replaced the position of lead solder paste in the electronics manufacturing industry, but this has also brought new problems to solder paste printing. . In the transition from lead to lead-free, the two biggest material problems involved are the selection of solder paste and components. Choosing the right solder paste determines the quality of electronic products to a certain extent, so it must be targeted before choosing.Like lead-free solder paste, there are many manufacturers and specifications. Even the solder paste from the...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-06-17

- Views:0

With the widespread development and popularization of lead-free, lead-free solder has been fully put into use. Lead-free solder paste has replaced the position of lead solder paste in the electronics manufacturing industry, but this has also brought new problems to solder paste printing. . In the transition from lead to lead-free, the two biggest material problems involved are the selection of solder paste and components. Choosing the right solder paste determines the quality of electronic products to a certain extent, so it must be targeted before choosing.

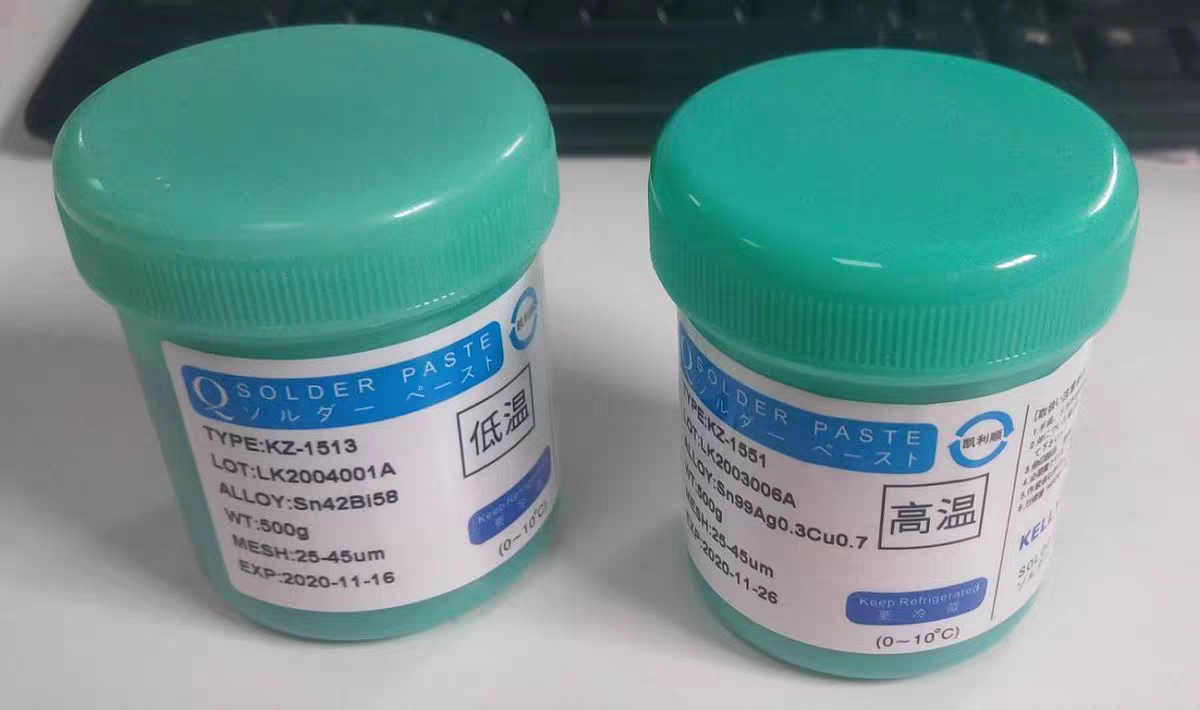

Like lead-free solder paste, there are many manufacturers and specifications. Even the solder paste from the same manufacturer has different specifications, and there are differences in alloy composition, particle size, viscosity, no-cleaning, solvent cleaning, and water cleaning. The alloy composition of the solder paste is mainly selected according to the electronic product and process, so the solder paste with an alloy composition compatible with the solder end of the component should be considered as much as possible when selecting. How should I choose? The following three crystal take you to find out.

This depends on the product itself, and different products should choose different solder pastes. At the same time, process tests should be conducted on solder pastes from different manufacturers, and some comparisons and evaluations should be made on printability, mold release, thixotropy, adhesion, wettability, solder joint defects, residues, etc., and qualified companies can Solder paste is tested, evaluated and certified. Products with high quality requirements must be certified for solder joint reliability.

In addition, the key to the printability and solderability of solder paste is the flux. The flux in the solder paste is a key material for purifying the soldering surface, improving wettability, preventing solder oxidation, ensuring the quality of the solder paste and excellent SMT manufacturability. Under high temperature, it can clean the oxide layer of PCB pads, component ends and pin surfaces, and activate the metal surface at the same time.

What are the requirements for flux in the lead-free process? Lead-free soldering requires flux to increase activity and activation temperature, so lead-free flux must be specially formulated, and VOC-free and no-clean fluxes in wave soldering also need to be specially formulated. At the same time, water-soluble flux is also essential for some products.

With the increase of flux activity and activation temperature, the quality of lead-free soldering has been greatly improved. The current lead-free solder joints have changed a lot from the appearance of previous years. It is worth noting that after selecting the lead-free alloy solder paste, it is necessary to test the lead-free solder paste with the same alloy composition provided by different manufacturers. If the test results are very different, the solder paste with good wettability will not be tombstoned after soldering, and the solder paste with poor wettability will have more resistance and capacitance displacement after soldering. In this case, a process test is required when selecting a solder paste. The purpose is It depends on whether the printing period can meet the requirements and the quality after welding. For example, whether the rolling, filling, and mold release properties of the solder paste are good during printing, observe whether there is any change in the printing quality at an interval of 1h, and test the viscosity change of 1~8h. Due to poor wettability, the management of lead-free solder paste is stricter than that of lead solder paste.

In short, no matter what kind of solder paste, the one that suits your product and PCBA process is the best.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback