新闻资讯banner

The performance of welding defects in PCBA manufacturing process

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-07-02

- Views:0

(Summary description)For PCBA products, no matter which part of the problem occurs, it will affect the performance of the entire product. Today we will mainly discuss the defects in the soldering process in the PCBA manufacturing process. The welding defects of PCBA in the manufacturing process can be roughly divided into the following situations: poor wetting, poor gloss, improper amount of solder, and inadequate cleaning. Each of the above situations will also cause different welding defect performance, the following Sanjing will share with you.

First, the first one is poor wetting. Poor wetting will result in poor wetting of the lead wires, producing bubbles and pinholes, and will also...

The performance of welding defects in PCBA manufacturing process

(Summary description)For PCBA products, no matter which part of the problem occurs, it will affect the performance of the entire product. Today we will mainly discuss the defects in the soldering process in the PCBA manufacturing process. The welding defects of PCBA in the manufacturing process can be roughly divided into the following situations: poor wetting, poor gloss, improper amount of solder, and inadequate cleaning. Each of the above situations will also cause different welding defect performance, the following Sanjing will share with you.

First, the first one is poor wetting. Poor wetting will result in poor wetting of the lead wires, producing bubbles and pinholes, and will also...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-07-02

- Views:0

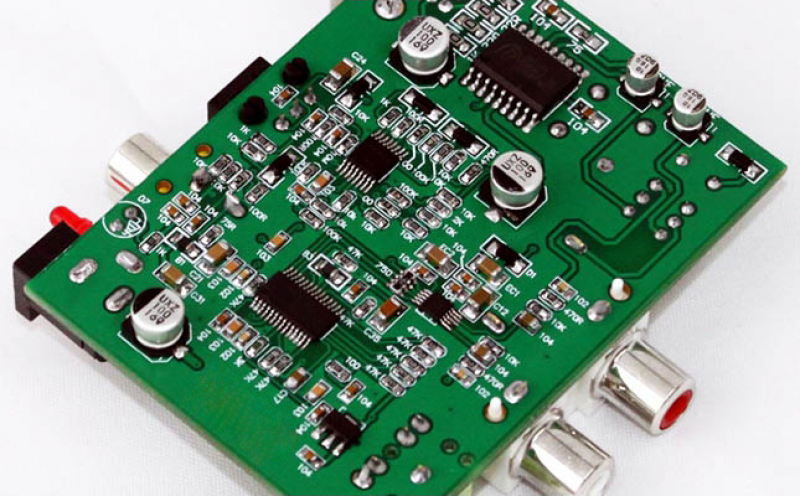

For PCBA products, no matter which part of the problem occurs, it will affect the performance of the entire product. Today we will mainly discuss the defects in the soldering process in the PCBA manufacturing process. The welding defects of PCBA in the manufacturing process can be roughly divided into the following situations: poor wetting, poor gloss, improper amount of solder, and inadequate cleaning. Each of the above situations will also cause different welding defect performance, the following Sanjing will share with you.

First, the first one is poor wetting. Poor wetting will result in poor wetting of the lead wires, producing bubbles and pinholes, and will also lead to non-fusion between the solder.

The second is poor gloss. Poor gloss can cause problems such as solder paste sharpening, solder joint bridging, and solder joint overheating.

Third, the amount of solder is improperly used. Improper use of the amount of solder can also cause non-fusion between the solders, and also cause the solder joints to form spherical surfacing, solder joints bridging, and solder paste sharpening.

Fourth, the cleaning is not in place. Inadequate cleaning will not only cause dirt and residual flux residues on the appearance of the circuit board, but also cause the solder to flow, flux splash and discoloration of the circuit board.

The above is the manifestation of various welding defects in the welding process of the entire PCBA manufacturing process, taking poor wetting as an example. There are many reasons for poor wetting, but the poor soldering in the PCBA manufacturing process is mostly caused by unskilled operators. At the same time, there are also defects caused by improper management of welding tools, such as wear on the tip of the soldering iron tip or defects caused by the temperature of the soldering iron tip being too high or too low. In addition, you should also understand the status of the components to be welded (whether they are normally available), production batch number, storage period, and surface treatment before starting welding.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback