新闻资讯banner

What are the production requirements for high-frequency purifier circuit boards

- Categories:Purifier circuit board

- Author:

- Origin:

- Time of issue:2022-08-04

- Views:0

(Summary description)High-frequency purifier circuit board refers to a special circuit board with high electromagnetic frequency. It is used for PCB in the field of high frequency and microwave. It is a part of the process of using ordinary rigid circuit board manufacturing methods on microwave substrate copper clad laminates or special processing methods. while producing circuit boards. The high-frequency purifier circuit board is one of the most difficult boards. So, what are the production requirements for the high-frequency purifier circuit board?

What are the production requirements for high-frequency purifier circuit boards

(Summary description)High-frequency purifier circuit board refers to a special circuit board with high electromagnetic frequency. It is used for PCB in the field of high frequency and microwave. It is a part of the process of using ordinary rigid circuit board manufacturing methods on microwave substrate copper clad laminates or special processing methods. while producing circuit boards. The high-frequency purifier circuit board is one of the most difficult boards. So, what are the production requirements for the high-frequency purifier circuit board?

- Categories:Purifier circuit board

- Author:

- Origin:

- Time of issue:2022-08-04

- Views:0

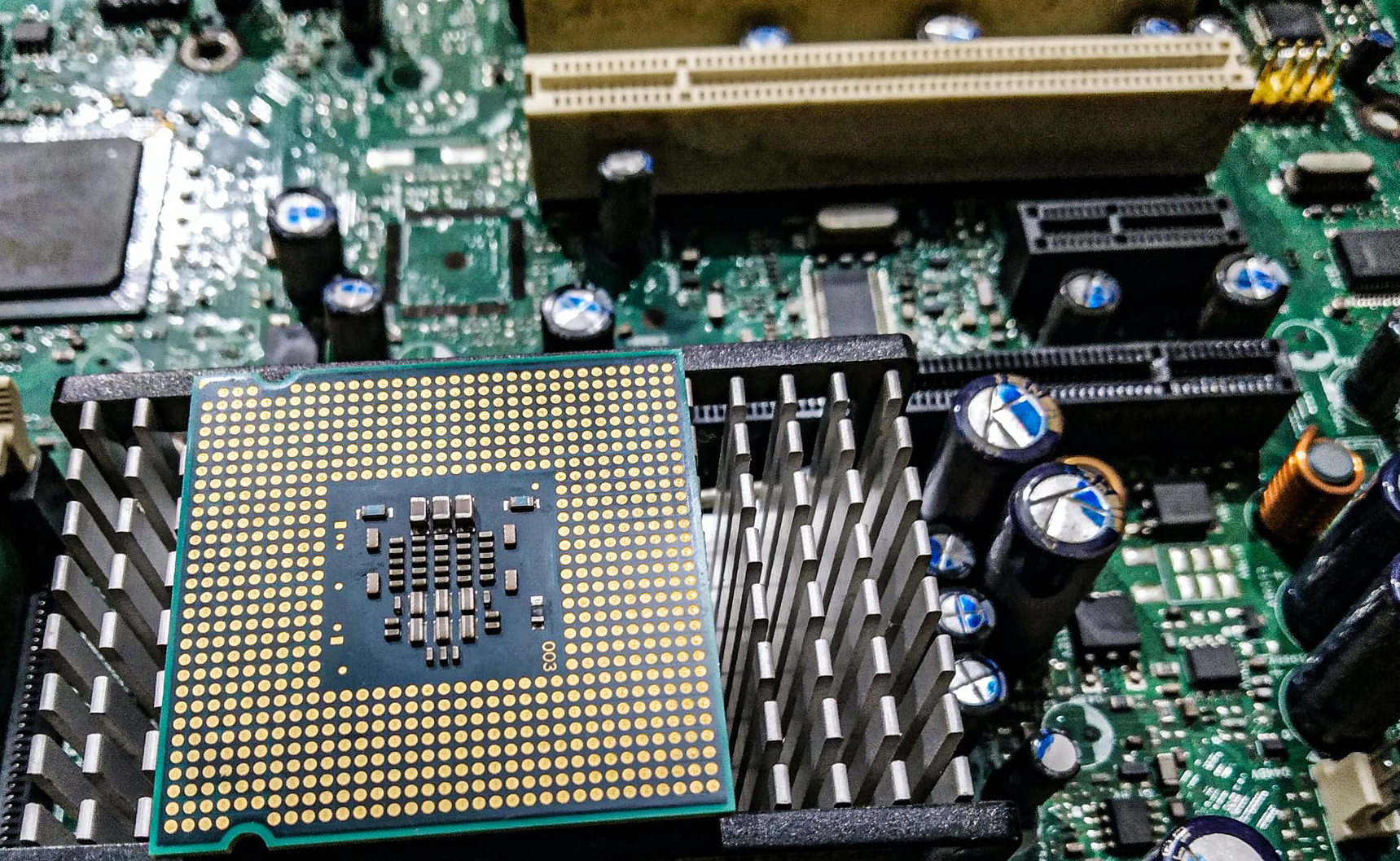

High-frequency purifier circuit board refers to a special circuit board with high electromagnetic frequency. It is used for PCB in the field of high frequency and microwave. It is a part of the process of using ordinary rigid circuit board manufacturing methods on microwave substrate copper clad laminates or special processing methods. while producing circuit boards. The high-frequency purifier circuit board is one of the most difficult boards. So, what are the production requirements for the high-frequency purifier circuit board?

First, the high-frequency purifier circuit board drilling

1. The feeding speed of drilling should be slow, the speed is 180/S, a new drill tip should be used, and aluminum sheets should be placed on the upper and lower sides. It is best to drill a single PNL hole, and the hole should not be exposed to water; 3. Special attention: high-frequency circuit boards do not need to remove glue residue.

2. Anti-welding

1. If green oil needs to be printed on the substrate of the high-frequency purifier circuit board, green oil should be printed twice (to prevent the green oil from bubbling on the substrate); the board should not be ground after etching and tin stripping, only air-drying. 2. If the circuit board of the high-frequency purifier needs green oil to be primed, it is not allowed to grind the board before the solder mask, and the red stamp is stamped in the MI. 3. If the circuit board of the high-frequency purifier needs to be printed with green oil on some substrates, green oil is not printed on some substrates.

3.spray tin

Before spraying tin, add baking at 150 degrees for 30min before spraying tin.

4.the circuit board tolerance of high frequency purifier

The line width tolerance without requirements is ±0.05mm, and there are requirements to make according to customer requirements.

5. Plate

See requirements to use the specified sheet. Because the price of the board is more expensive, only 1PNL can be opened if only 1PNL can be opened.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback