新闻资讯banner

About liquid solder wetting in PCBA soldering

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-07-09

- Views:0

(Summary description)Generally speaking, in the daily SMT processing detail control, there is one link that is most easily overlooked by everyone, which is solder wetting. What is the effect of solder wetting? Let's take a brief look at Sanjing below.

We know that in the PCBA welding process, only when the molten liquid solder spreads on the metal surface, can the metal atoms be freely approached, which is conducive to the formation of a bonding layer on the surface of the weldment. Therefore, wetting the surface of the weldment by the molten solder is the primary condition for diffusion, dissolution, and formation of the bonding layer.

However, wetting must also meet certain conditions, such as:

①The liquid solder has a good affinity with the base metal and can dissolve each other...

About liquid solder wetting in PCBA soldering

(Summary description)Generally speaking, in the daily SMT processing detail control, there is one link that is most easily overlooked by everyone, which is solder wetting. What is the effect of solder wetting? Let's take a brief look at Sanjing below.

We know that in the PCBA welding process, only when the molten liquid solder spreads on the metal surface, can the metal atoms be freely approached, which is conducive to the formation of a bonding layer on the surface of the weldment. Therefore, wetting the surface of the weldment by the molten solder is the primary condition for diffusion, dissolution, and formation of the bonding layer.

However, wetting must also meet certain conditions, such as:

①The liquid solder has a good affinity with the base metal and can dissolve each other...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-07-09

- Views:0

Generally speaking, in the daily SMT processing detail control, there is one link that is most easily overlooked by everyone, which is solder wetting. What is the effect of solder wetting? Let's take a brief look at Sanjing below.

We know that in the PCBA welding process, only when the molten liquid solder spreads on the metal surface, can the metal atoms be freely approached, which is conducive to the formation of a bonding layer on the surface of the weldment. Therefore, wetting the surface of the weldment by the molten solder is the primary condition for diffusion, dissolution, and formation of the bonding layer.

However, wetting must also meet certain conditions, such as:

①The liquid solder has a good affinity with the base metal and can dissolve each other. The degree of mutual solubility between the liquid solder and the base metal depends on the lattice type and atomic radius.

②The surface of liquid solder and base metal is clean, free of oxide layer and pollutants. The clean surface brings the solder and the atoms of the base material in close proximity, creating gravitational force (wetting force). When there is an oxide layer and other contaminants between the solder and the metal to be welded, it will prevent the metal atoms from freely approaching, and can not produce wetting effect, resulting in the formation of virtual welding. This is one of the reasons for the formation of virtual solder in the patch processing.

It can be seen that wetting force is an important factor affecting welding quality. Similarly, there are many factors that affect wetting power, such as:

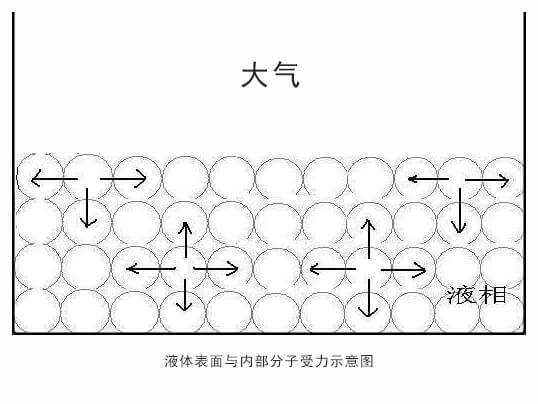

1. Surface tension. In a system where different phases coexist, the phenomenon that the phase interface always tends to the smallest due to the difference in the forces between the phase interface molecules and the molecules in the bulk phase is called surface tension.

For example, a glass of water (as shown in the picture), because the molecules inside the liquid are symmetrical by the forces of the surrounding molecules, the effect is offset by this, and the resultant force is zero. However, the gravitational force of the molecules on the liquid surface is greater than the gravitational force of the atmospheric molecules on it, so the liquid surface has a tendency to shrink to a minimum automatically.

Wetting is the force of liquid flowing on the solid surface, and surface tension is the force of liquid shrinking on the solid surface. The direction of surface tension is opposite to the direction of wetting force, so surface tension is not conducive to wetting. The molten solder also automatically shrinks to the smallest surface tension on the metal surface. Therefore, the degree of wetting of the molten solder on the metal surface is related to the surface tension of the liquid solder.

2. Viscosity. The viscosity is proportional to the surface tension. The greater the viscosity, the worse the fluidity of the solder, which is not conducive to wetting.

3. The composition of the alloy. Different alloys and different alloys have different composition ratios, and their viscosity and surface tension are different. The viscosity and surface tension of tin-lead alloy are closely related to the composition of the alloy.

4. Temperature. Increasing temperature can reduce viscosity and surface tension.

Finally, through the above analysis, we can understand that liquid solder wetting is very important in the PCBA soldering process, so this detail cannot be ignored.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback