新闻资讯banner

Quality inspection method after SMT welding process

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-23

- Views:0

(Summary description)We know that for manufacturing enterprises, quality inspection is an indispensable step. Whether in the production process or after production, each production link needs to carry out quality control from time to time, that is, quality inspection. Today we mainly come to understand the quality inspection and methods after SMT welding processing.

First of all, the first is the triangulation method. This detection method is mainly used to check the three-dimensional shape. The currently developed triangulation method can detect the cross-sectional shape of the device, but this measurement method is from different light incidents, different directions, and the observation results will be different.

Second, the light reflection distribution measurement method. This inspection method mainly uses welding parts to detect decorations, incident light inward from an oblique direction, set up a TV camera above, and then inspect it. The most important function of this method of operation...

Quality inspection method after SMT welding process

(Summary description)We know that for manufacturing enterprises, quality inspection is an indispensable step. Whether in the production process or after production, each production link needs to carry out quality control from time to time, that is, quality inspection. Today we mainly come to understand the quality inspection and methods after SMT welding processing.

First of all, the first is the triangulation method. This detection method is mainly used to check the three-dimensional shape. The currently developed triangulation method can detect the cross-sectional shape of the device, but this measurement method is from different light incidents, different directions, and the observation results will be different.

Second, the light reflection distribution measurement method. This inspection method mainly uses welding parts to detect decorations, incident light inward from an oblique direction, set up a TV camera above, and then inspect it. The most important function of this method of operation...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-08-23

- Views:0

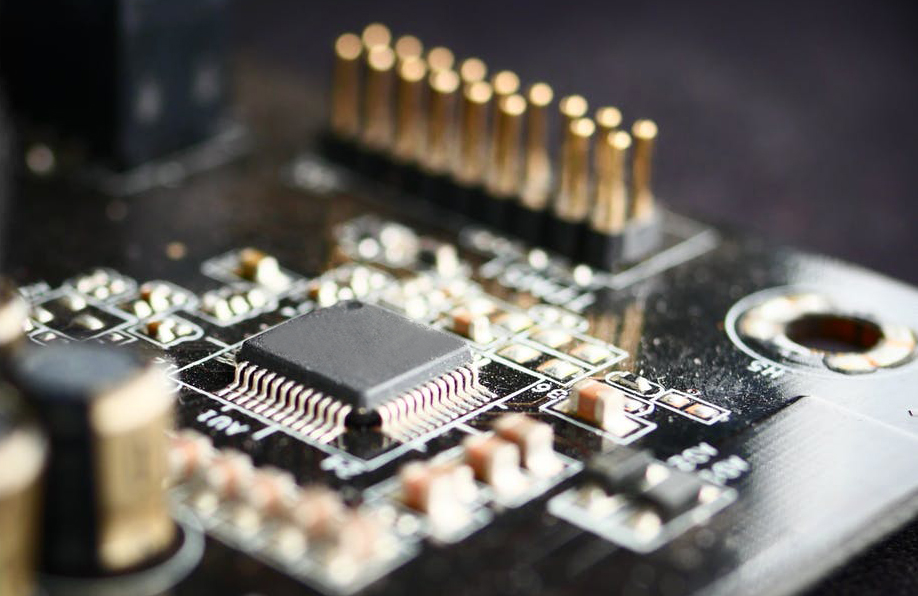

We know that for manufacturing enterprises, quality inspection is an indispensable step. Whether in the production process or after production, each production link needs to carry out quality control from time to time, that is, quality inspection. Today we mainly come to understand the quality inspection and methods after SMT welding processing.

First of all, the first is the triangulation method. This detection method is mainly used to check the three-dimensional shape. The currently developed triangulation method can detect the cross-sectional shape of the device, but this measurement method is from different light incidents, different directions, and the observation results will be different.

Second, the light reflection distribution measurement method. This inspection method mainly uses welding parts to detect decorations, incident light inward from an oblique direction, set up a TV camera above, and then inspect it. The most important function of this method of operation is to measure the surface angle of the SMT patch solder, especially the illuminance information, etc. It is necessary to capture the angle information through a variety of light colors. On the contrary, if it is irradiated from above, the angle measured is the reflected light distribution. In this case, check the inclined surface of the solder.

Third, change the angle of inspection. To use this inspection method to detect the quality of the SMT patch after welding, there must be a device that can change the angle. This device generally needs to be equipped with at least 5 cameras, multiple LED lighting devices, use multiple images at the same time, and use visual inspection conditions for inspection, which is relatively reliable.

The last is the focus detection method. For some high-density circuit boards, after professional SMT soldering processing, the above-mentioned methods are difficult to detect the final result, so other methods, namely the focus utilization method, are needed. There are many types of this method, such as the multi-segment focus method. This method can directly detect the height of the solder surface to achieve a high-precision detection method. If 10 focus surface detectors are set at the same time, the focus surface can be obtained by seeking the maximum output. The position of the solder surface is detected.

The above content is about the quality inspection method after SMT welding process, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback