新闻资讯banner

SMT common defects and their causes

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-28

- Views:0

(Summary description)We know that whether it is SMT patch or PCBA production, there will be more or less bad situations. Today, Sanjing mainly takes you to understand the common defects and their causes in SMT.

Common defects in SMT mainly include: solder ball, tombstone, short circuit, offset, low solder/open circuit, etc. Below we will introduce the causes of these defects in turn.

1. Tin ball. 1. Before printing, the solder paste has not been fully warmed to thaw, or has not been stirred evenly. 2. If there is no reflow for too long after printing, the solvent will evaporate, and the paste will become dry powder and fall onto the ink. 3. The printing is too thick, and the excess solder paste overflows after the component is pressed down. 4. The mounting pressure is too large, and the downward pressure causes the solder paste to...

SMT common defects and their causes

(Summary description)We know that whether it is SMT patch or PCBA production, there will be more or less bad situations. Today, Sanjing mainly takes you to understand the common defects and their causes in SMT.

Common defects in SMT mainly include: solder ball, tombstone, short circuit, offset, low solder/open circuit, etc. Below we will introduce the causes of these defects in turn.

1. Tin ball. 1. Before printing, the solder paste has not been fully warmed to thaw, or has not been stirred evenly. 2. If there is no reflow for too long after printing, the solvent will evaporate, and the paste will become dry powder and fall onto the ink. 3. The printing is too thick, and the excess solder paste overflows after the component is pressed down. 4. The mounting pressure is too large, and the downward pressure causes the solder paste to...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-28

- Views:0

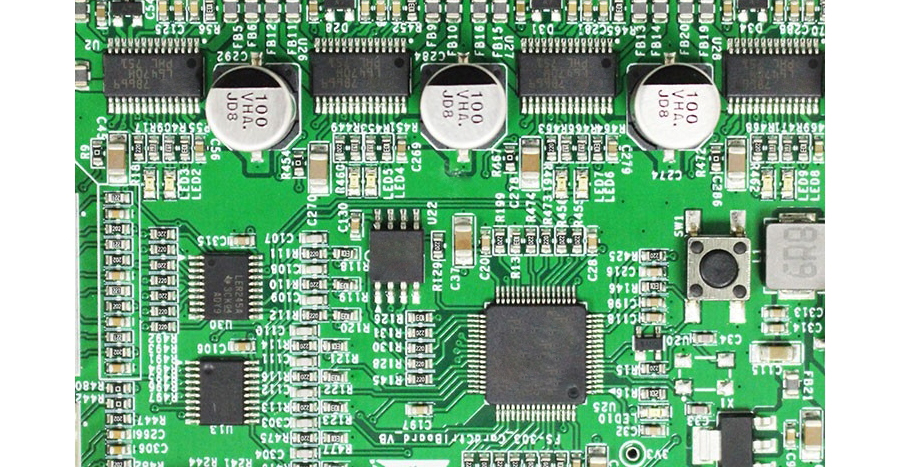

We know that whether it is SMT patch or PCBA production, there will be more or less bad situations. Today, Sanjing mainly takes you to understand the common defects and their causes in SMT.

Common defects in SMT mainly include: solder ball, tombstone, short circuit, offset, low solder/open circuit, etc. Below we will introduce the causes of these defects in turn.

1. Tin ball. 1. Before printing, the solder paste has not been fully warmed to thaw, or has not been stirred evenly. 2. If there is no reflow for too long after printing, the solvent will evaporate, and the paste will become dry powder and fall onto the ink. 3. The printing is too thick, and the excess solder paste overflows after the component is pressed down. 4. The mounting pressure is too large, and the downward pressure causes the solder paste to collapse onto the ink. 5. Environmental impact: The humidity is too high, the normal temperature is 25±5℃, the humidity is 40%~60%, and it can reach 95% when it rains. At this time, dehumidification is required. 6. The activity of the solder paste is not good, such as drying too fast, or too much tin powder with small particles. 7. The solder paste is exposed to an oxidizing environment for too long, and moisture in the air penetrates. 8. Insufficient preheating, too slow and uneven heating time. 9. The printing is offset, and part of the solder paste is stained on the PCB.

Second, erect the monument. 1. Uneven printing (large tin thickness on one side and small tin thin tension on one side) or too much deviation, causing one end of the component to be pulled to the other side to form an empty solder, and one end to be pulled up to form a tombstone. 2. The patch is offset, causing uneven force on both sides. 3. The electrode at one end is oxidized, or the difference in electrode size is too large, and the tinning performance is poor, causing uneven force at both ends. 4. The solder paste is volatilized after being placed for too long after printing, resulting in reduced activity.

3. Short circuit. 1. The steel plate is not cleaned in time, and the scraper pressure is set improperly or deformed. 2. Excessive printing pressure makes the printed graphics blurry; 3. Poor incoming materials, such as poor IC pin coplanarity. 4. The solder paste is too thin, including low metal or solid content in the solder paste. 5. The solder paste particles are too large and the surface tension of the flux is too small.

4. Offset. 1. Inaccurate placement accuracy; 2. Insufficient solder paste adhesion; 3. PCB vibration at the entrance of the furnace; 4. PCBA design is not compatible.

5. Less tin/open circuit. 1. The amount of tin is insufficient or the tin paste is too thin, causing tin loss; 2. The board surface temperature is uneven; 3. The component coplanarity is not good, the pin is tin sucking or there is a connection hole nearby; 4. The heating is uneven, the component The pin temperature is too high, causing the solder paste to be led to the pin, and the PAD has less solder.

The above content is about the common defects and causes of SMT, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback