新闻资讯banner

SMT patch dispensing process control

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-05

- Views:0

(Summary description)Before introducing the control of the dispensing process, I will give you a brief introduction to the dispensing process. The dispensing process is mainly used for lead component through-hole insertion (THT) and surface mount (SMT) coexistence of the placement and insertion mixed process. In the entire production process, after one side of the PCB circuit board components are glued and cured, they can finally be wave soldered. The interval is longer and other processes are performed more frequently, so the curing of the components is extremely important. Today, Sanjing will mainly take you to understand the process control of dispensing in the SMT patch production process.

First of all, the first is the material and process parameters in dispensing: ...

SMT patch dispensing process control

(Summary description)Before introducing the control of the dispensing process, I will give you a brief introduction to the dispensing process. The dispensing process is mainly used for lead component through-hole insertion (THT) and surface mount (SMT) coexistence of the placement and insertion mixed process. In the entire production process, after one side of the PCB circuit board components are glued and cured, they can finally be wave soldered. The interval is longer and other processes are performed more frequently, so the curing of the components is extremely important. Today, Sanjing will mainly take you to understand the process control of dispensing in the SMT patch production process.

First of all, the first is the material and process parameters in dispensing: ...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-07-05

- Views:0

Before introducing the control of the dispensing process, I will give you a brief introduction to the dispensing process. The dispensing process is mainly used for lead component through-hole insertion (THT) and surface mount (SMT) coexistence of the placement and insertion mixed process. In the entire production process, after one side of the PCB circuit board components are glued and cured, they can finally be wave soldered. The interval is longer and other processes are performed more frequently, so the curing of the components is extremely important. Today, Sanjing will mainly take you to understand the process control of dispensing in the SMT patch production process.

First of all, the first is the material and process parameters in dispensing: ①Material parameters generally need to be considered: drying or aging characteristics, temperature, flow characteristics, viscosity, homogeneity of the mixture, wetting characteristics, and whether there is air, etc. ②Process parameters generally need to be considered: tact time, pump control accuracy, distance between the needle tip and the substrate, X/Y accuracy and repeatability, needle tip inner diameter, Z axis accuracy and repeatability, needle tip design, etc.

2. Adhesive viscosity requirements. This depends on which coating method is used. If the coating method is different, the viscosity of the adhesive will be different. For example: 1. Needle printing method, when the SMC/SMD shape is cylindrical, the viscosity requirement is 15±5Pa.S; 2. Dispensing method, when the SMC/SMD shape is rectangular, the viscosity requirement is 70±5Pa.S ; 3. Screen printing method, when the SMC/SMD shape is rectangular, the viscosity is required to be 300±10Pa.S, and when the SMC/SMD shape is cylindrical, the viscosity is required to be 200±10Pa.S.

3. The size of the dispensing volume. The size of the glue dot diameter should be half of the pad spacing, so that there is enough glue to bond the components, and at the same time, it can avoid too much glue to impregnate the pads. The size of the glue dot is determined by the length of the glue dispensing time and the amount of glue.

4. Dispensing pressure

The glue dispenser uses pressure to the glue barrel of the glue head to ensure that there is enough glue to squeeze out. Too much pressure will easily cause too much glue, and too little pressure will cause intermittent glue dispensing. Therefore, the pressure should be selected according to the quality of the glue and the temperature of the working environment.

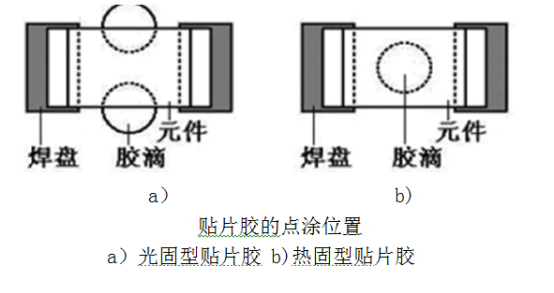

5. The dispensing position of the patch glue

6. Dispensing nozzle size

The inner diameter of the dispensing nozzle should be 1/2 of the diameter of the dispensing dot. During the dispensing process, the dispensing nozzle should be selected according to the size of the pad on the PCB. If the pad size is not much different, the same needle can be selected, but If the pads are quite different, different dispensing nozzles should be selected, which can not only ensure the quality of the glue dots, but also improve the production efficiency.

7. The distance between the dispensing nozzle and the PCB board

The distance between the glue nozzle and the PCB board is a necessary factor to ensure the proper diameter-to-height ratio of the glue dot. Generally, for low-viscosity materials, the diameter-to-height ratio should be approximately 3:1, and for high-viscosity solder paste, it should be 2:1.

8. Glue temperature

Generally, epoxy resin glue should be stored in a refrigerator at 0~5℃, and should be taken out half an hour before use, so that the glue is fully in line with the working temperature. The use temperature of the glue should be 23~25℃. The ambient temperature has a great influence on the viscosity of the glue. If the temperature is too low, the glue point will become smaller, which will cause the phenomenon of wire drawing. A difference of 5°C between the ambient temperature will cause a 50% change in the dispensing volume, so the ambient temperature should be controlled.

The above are the process control requirements in the dispensing process, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback