新闻资讯banner

SMT template printing operation mode and parameter setting

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-06-04

- Views:0

(Summary description)SMT template is a thin metal material cut into circuit land patterns. The most common metal materials are brass and stainless steel. In surface mount components, SMT templates are not only accurately placed, but also reproducible solder paste can be deposited. SMT template printing has two modes of operation: contact printing and gap printing. Let's discuss the setting of printing parameters when printing with 250um thick metal and plastic SMT stencils.1. Contact printingIn contact printing, since the template has a relatively small thickness, the glue dot...

SMT template printing operation mode and parameter setting

(Summary description)SMT template is a thin metal material cut into circuit land patterns. The most common metal materials are brass and stainless steel. In surface mount components, SMT templates are not only accurately placed, but also reproducible solder paste can be deposited. SMT template printing has two modes of operation: contact printing and gap printing. Let's discuss the setting of printing parameters when printing with 250um thick metal and plastic SMT stencils.1. Contact printingIn contact printing, since the template has a relatively small thickness, the glue dot...

- Categories:SMT technology article

- Author:SAJ

- Origin:

- Time of issue:2021-06-04

- Views:0

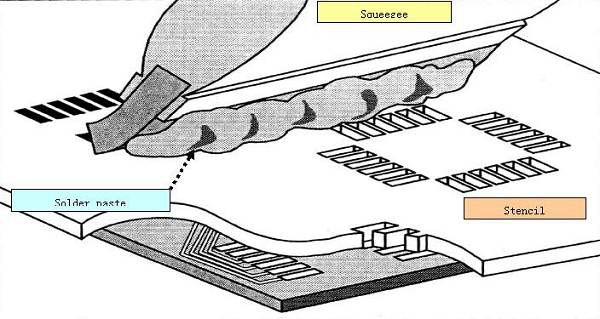

SMT template is a thin metal material cut into circuit land patterns. The most common metal materials are brass and stainless steel. In surface mount components, SMT templates are not only accurately placed, but also reproducible solder paste can be deposited. SMT template printing has two modes of operation: contact printing and gap printing. Let's discuss the setting of printing parameters when printing with 250um thick metal and plastic SMT stencils.

1. Contact printing

In contact printing, since the template has a relatively small thickness, the glue dot height is limited. For large glue dots of 1.8mm, the squeegee will scrape off the glue, and the height of the glue after printing is almost the same as the thickness of the template; for medium-sized glue dots (such as 0.8mm), irregular glue dot shapes may occur because of the patch glue The adhesive force with the template and the PCB is almost equal. During the separation of the template and the PCB, the template lengthens the glue, so the glue dot height is greater than the thickness of the template: 0.3~0.6mm size glue dots, due to the force of the patch glue and the template Better than PCB, part of the glue stays in the template, the glue dot height is low, and the consistency is very good.

2. There is gap printing

It is printed with a thin template. When there is a certain gap between the SMT template and the PCB, a high glue point can be reached. The glue is squeezed in the gap between the bottom surface of the template and the PCB. When the template and the PCB are slowly separated (such as The speed is 0.5m/s), the glue is pulled out and dropped. According to the different rheological properties of the glue, one or more cone-shaped glue dots can be obtained.

3. Recommended parameters for printing with 250um thick SMT template

a. Printing speed: 50mm/s.

b. Printing order: two-way printing or one-way printing can be selected.

c. Scraper: metal scraper. Scraper hardness is a more sensitive process parameter. The blade of a low-hardness scraper will "empty" the patch glue in the leaking hole of the template, so a metal scraper with higher hardness is used.

d. The original printing room: 1mm or higher glue dots, the gap is 0.6mm: If only small glue dots are printed, the printing gap can be zero.

e. The separation speed of PCB and template: 0.1~0.5mm/s.

f. Separation height: >3mm (should be higher than the glue point height).

4. Recommended parameters for pump printing with a 1mm thick plastic template (recommended by DEK)

a. Scraper: 45° angle of metal auxiliary knife.

b. Squeegee pressure: 0.33kg/cm.

c. SMT printing speed: 25mm/s.

d. Printing order: single-pass printing.

e. Printing room position: 0mm (contact type).

f. Separation speed: 0.2mm/cm.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback