新闻资讯banner

The influence of PCB on PCBA processing quality

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-06-21

- Views:0

(Summary description)As we all know, the entire PCBA manufacturing process is very complicated. Although PCB and PCBA are only one word difference, in fact their processes are very different. PCBA is a series of back-end processes on the basis of PCB, such as solder paste printing, SPI solder paste inspection, SMT processing, reflow soldering, DIP plug-in post soldering, wave soldering/selective wave soldering, PCBA first piece inspection, etc. Because of this, the quality of PCBA depends on the PCB. On the other hand, the quality of the PCB determines the quality of the entire PCBA. So what aspects of PCB have an impact on PCBA? The following Sanjing will share with you.

First of all, the first is the...

The influence of PCB on PCBA processing quality

(Summary description)As we all know, the entire PCBA manufacturing process is very complicated. Although PCB and PCBA are only one word difference, in fact their processes are very different. PCBA is a series of back-end processes on the basis of PCB, such as solder paste printing, SPI solder paste inspection, SMT processing, reflow soldering, DIP plug-in post soldering, wave soldering/selective wave soldering, PCBA first piece inspection, etc. Because of this, the quality of PCBA depends on the PCB. On the other hand, the quality of the PCB determines the quality of the entire PCBA. So what aspects of PCB have an impact on PCBA? The following Sanjing will share with you.

First of all, the first is the...

- Categories:PCBA technical articles

- Author:SAJ

- Origin:

- Time of issue:2021-06-21

- Views:0

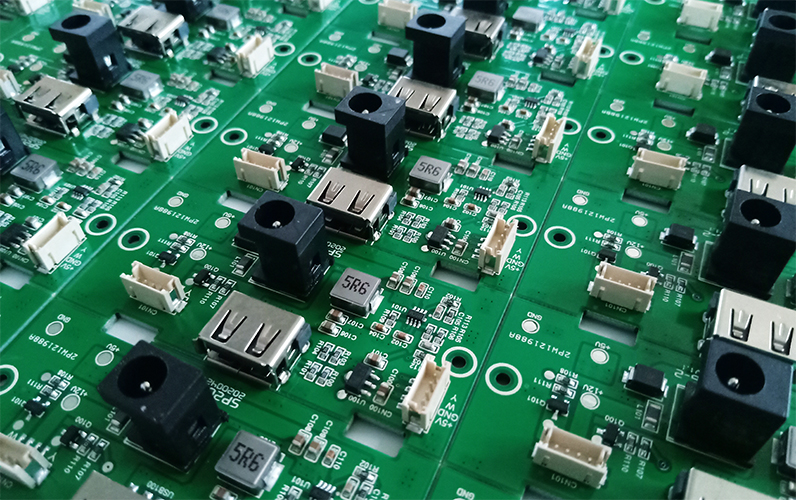

As we all know, the entire PCBA manufacturing process is very complicated. Although PCB and PCBA are only one word difference, in fact their processes are very different. PCBA is a series of back-end processes on the basis of PCB, such as solder paste printing, SPI solder paste inspection, SMT processing, reflow soldering, DIP plug-in post soldering, wave soldering/selective wave soldering, PCBA first piece inspection, etc. Because of this, the quality of PCBA depends on the PCB. On the other hand, the quality of the PCB determines the quality of the entire PCBA. So what aspects of PCB have an impact on PCBA? The following Sanjing will share with you.

First of all, the first is the cleanliness of the PCB board surface, which is generally manifested as a dirty board surface. The dirty board surface is mainly due to the high solid content of the flux, too much coating amount, too high or too low preheating temperature, or too dirty PCB clamping claws of the conveyor belt, excessive oxides and tin dross in the solder tank, etc. Caused. The main solution is to select the appropriate flux; control the amount of flux coating; control the preheating temperature; check the cleaning effect of the automatic cleaning of the PCB clamping jaws and take measures; timely clean up the oxide and tin dross on the surface of the solder tank.

The second is the PCB board surface residue, which is generally white. White residue is commonly known as hoarfrost. Although it does not affect the surface insulation resistance, it will affect the appearance of the board to a certain extent, and ordinary customers will not accept it. Solution: Use flux first, then clean with solvent. If it cannot be cleaned, it may be due to the flux expired and aging, or exposed to the air to absorb moisture, or it may be due to the high moisture content in the cleaning agent (solvent), or the flux does not match the cleaning agent. In this case, please supply The supplier assists in solving or replacing the flux and cleaning agent.

The third is PCB deformation. PCB deformation is mainly caused by large PCB size or uneven layout of components. The best solution is to distribute the components as evenly as possible when designing the PCB, design a support band in the middle of the large-size PCB (2~3mm wide non-placement area), or use a mass-balanced component to press on the PCB. The components are rare. The position to achieve mass balance during welding.

Okay, that's all for today's sharing, I hope it can be helpful to everyone!

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback