新闻资讯banner

Why do PCBA circuit boards need to be cleaned

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-06

- Views:0

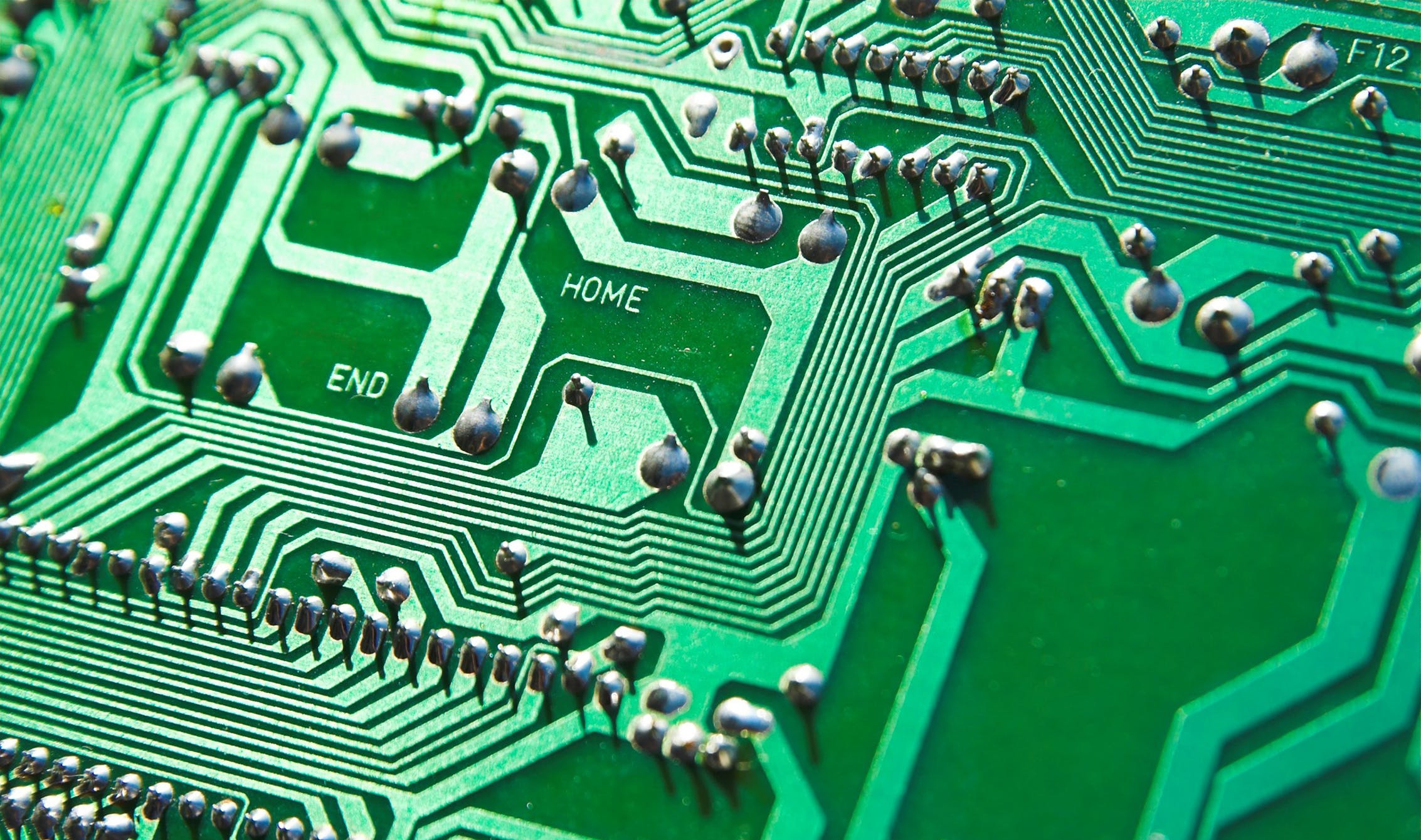

(Summary description)Circuit board cleaning is often overlooked in the PCBA manufacturing process. Many PCBA manufacturers feel that this step is not very important. However, in the long-term use of the product, the problems caused by the ineffective cleaning of the PCBA in the early stage can easily lead to many failures and increase the cost of repair. The following Sanjing will take you to understand why PCBA circuit boards should be cleaned:

The PCBA production process will go through many process stages, and the degree of pollution at each stage is different. Therefore, many impurities are prone to remain on the surface of the PCBA circuit board. These pollutants will not only reduce the product performance, but may even cause the circuit board to fail. For example, solder paste or flux is used for auxiliary soldering during the soldering process. The residue produced after...

Why do PCBA circuit boards need to be cleaned

(Summary description)Circuit board cleaning is often overlooked in the PCBA manufacturing process. Many PCBA manufacturers feel that this step is not very important. However, in the long-term use of the product, the problems caused by the ineffective cleaning of the PCBA in the early stage can easily lead to many failures and increase the cost of repair. The following Sanjing will take you to understand why PCBA circuit boards should be cleaned:

The PCBA production process will go through many process stages, and the degree of pollution at each stage is different. Therefore, many impurities are prone to remain on the surface of the PCBA circuit board. These pollutants will not only reduce the product performance, but may even cause the circuit board to fail. For example, solder paste or flux is used for auxiliary soldering during the soldering process. The residue produced after...

- Categories:FAQ

- Author:SAJ

- Origin:

- Time of issue:2021-09-06

- Views:0

Circuit board cleaning is often overlooked in the PCBA manufacturing process. Many PCBA manufacturers feel that this step is not very important. However, in the long-term use of the product, the problems caused by the ineffective cleaning of the PCBA in the early stage can easily lead to many failures and increase the cost of repair. The following Sanjing will take you to understand why PCBA circuit boards should be cleaned:

The PCBA production process will go through many process stages, and the degree of pollution at each stage is different. Therefore, many impurities are prone to remain on the surface of the PCBA circuit board. These pollutants will not only reduce the product performance, but may even cause the circuit board to fail. For example, solder paste or flux is used for auxiliary soldering during the soldering process. The residue produced after soldering contains organic acids and ions. The organic acids will corrode the circuit board, and the electric ions may cause the circuit board to short circuit or even fail.

There are many kinds of pollutants on the circuit board, which can generally be divided into two categories: ionic and non-ionic: ionic pollutants contact the humidity in the environment, and electrochemical migration occurs after electrification, forming a dendritic structure, resulting in a low-resistance path , Thereby destroying the function of the circuit board.

Non-ionic pollutants can penetrate the insulation layer of the PCB and grow dendrites under the surface of the PCB. In addition, there are granular contaminants, such as solder balls, floating points in the solder bath, dust, dust, etc. These contaminants can cause the quality of the solder joints to decrease, such as the solder joints are sharpened, pores or short circuits during soldering, etc. A variety of undesirable phenomena.

Among these pollutants, post-soldering residues are generally of greater influence, because solder paste or flux is commonly used in wave soldering and reflow soldering processes. The main components are solvents, lubricants, corrosion inhibitors and activators. , These solvents will produce thermally modified products after welding, which account for the majority of contaminants. From the perspective of product failure, post-welding residues are the most important factor affecting welding quality. Ionic residues can easily cause electromigration, thereby reducing insulation resistance; rosin resin residues are easy to absorb dust or impurities, which can easily cause contact resistance to increase. If it is large, it will cause the product to open circuit and fail.

Therefore, in view of the above problems, if you want to ensure the quality of the PCBA circuit board, the circuit board has to be cleaned after soldering.

Scan the QR code to read on your phone

Copyright©Sanjing Electronic Technology Co., Ltd. All Rights Reserved 粤ICP备09210657号

400-1668-717

400-1668-717

Feedback

Feedback